Gridding packaging adhesive film and preparation method thereof

A technology of encapsulating adhesive film and gridding, which is applied in the direction of adhesives, films/sheets without carriers, coatings, etc., which can solve the deviation of the shape of the gridded reflective layer, reduce the power generation efficiency of photovoltaic cell modules, and the thickness of the grid Uneven problems, to achieve the effect of uniform and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

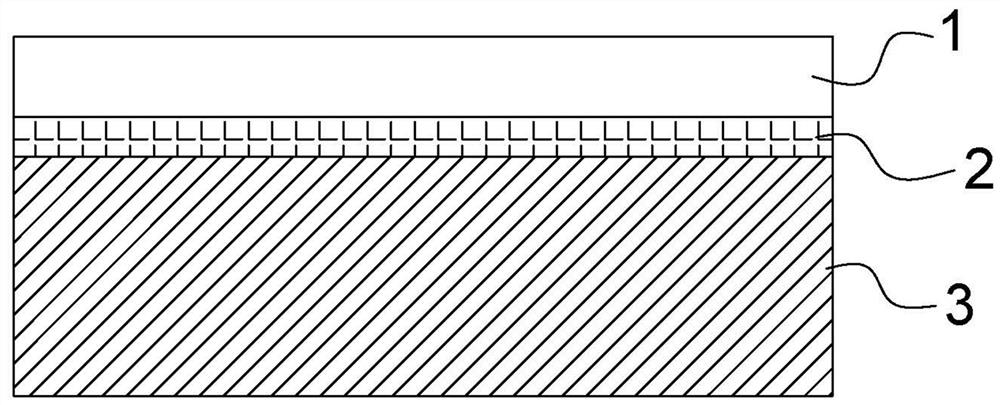

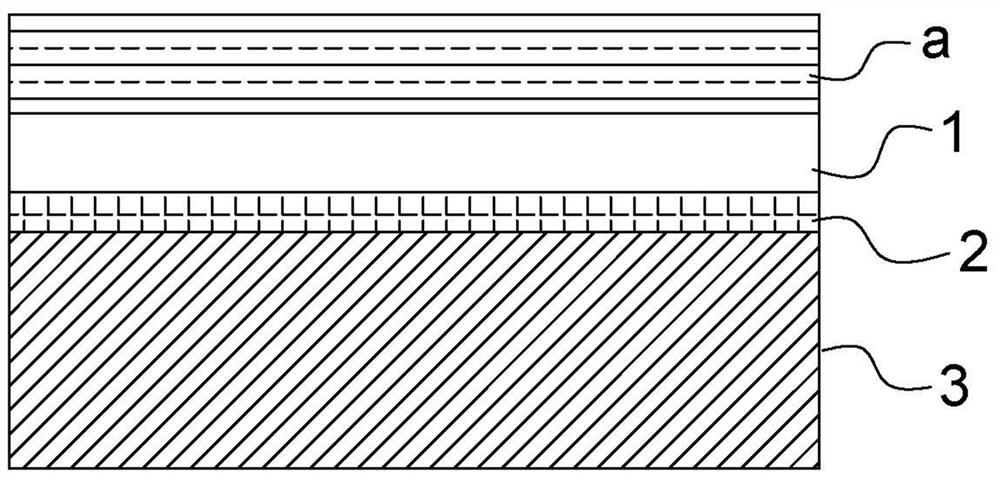

[0037] Example: Reference figure 1 , gridded encapsulation film, usually used for the rear encapsulation film of the photovoltaic power generation module, that is, after the photovoltaic power generation module is assembled, there are still cells, front encapsulation film and front photovoltaic tempered glass etc. member.

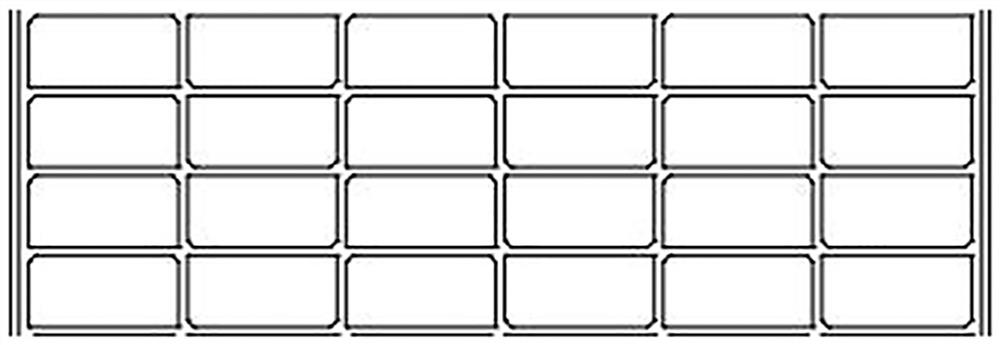

[0038] The gridded encapsulation adhesive film is composed of an adhesive film surface layer 1 , a reflective grid layer 2 and a transparent adhesive film layer 3 arranged in sequence adjacent to the battery sheet.

[0039] Among them, the surface layer 1 of the adhesive film is a transparent and weather-resistant layered body with a thickness of 15-50 μm, and it is easy to form a flat surface, which is used to provide the attachment basis for the reflective mesh layer 2. Because its surface is flat, it can be It is easy to control the reflective grid layer 2 to form a grid layer with uniform thickness on it, so that the local outflow / deformation phenomeno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com