Novel water storage artificial turf system structure

A technology of artificial turf and system structure, which is applied in the manufacture of rayon, one-component polyolefin rayon, textile and paper making, etc., can solve the problem of poor dimensional stability, low friction between recyclable artificial turf and elastic pad, and the surface of turf. High temperature problems, to achieve long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

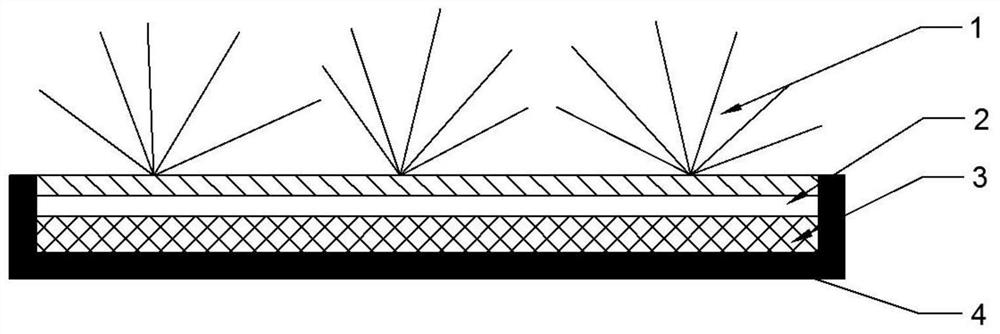

[0056] Recyclable artificial turf 1: The back is non-woven hot-melt adhesive artificial turf, the row spacing is 5 / 8, the number of stitches is 16, the grass height is 40mm, and the lawn weight is 1kg / m 2 ;

[0057] Damping cloth layer 2: The weight of non-woven fabric is 200g / m 2 , PVC single side point plastic weight 70g / m 2 , the density of spot molding is 20,000 pieces / m 2 .

[0058] Elastic cushion layer 3: 3D silk cushion layer with a thickness of 8mm. After mixing 80kg copolymerized PP, 14kg polyethylene, 4kg color masterbatch and 2 parts of stabilizing additives, it is extruded through a single-screw extruder, and extruded through a spinneret die. Out of the cooling water to cool and shape, the 3D wire is solid, and the diameter of the 3D wire is 1mm.

[0059] Water storage tank 4: The depth of the water storage tank is 8mm.

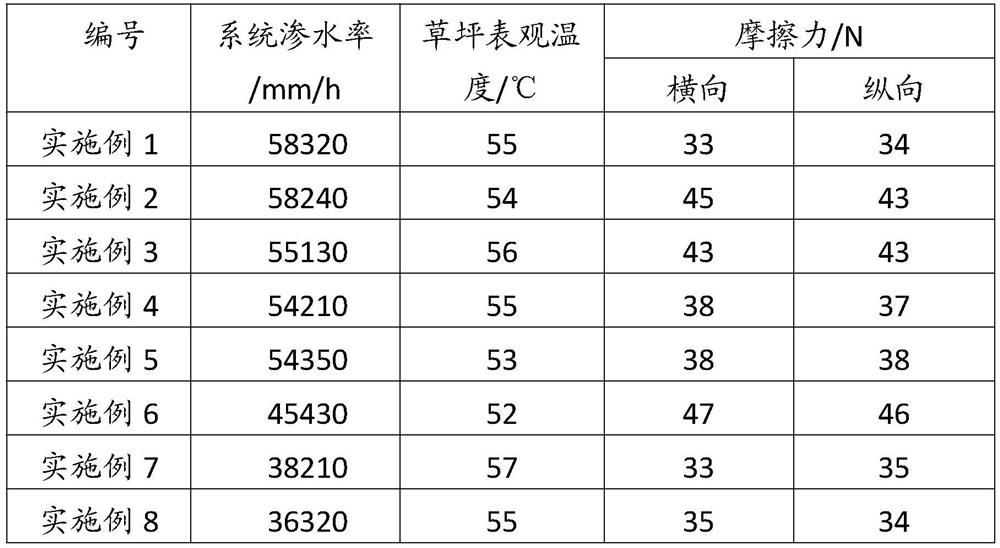

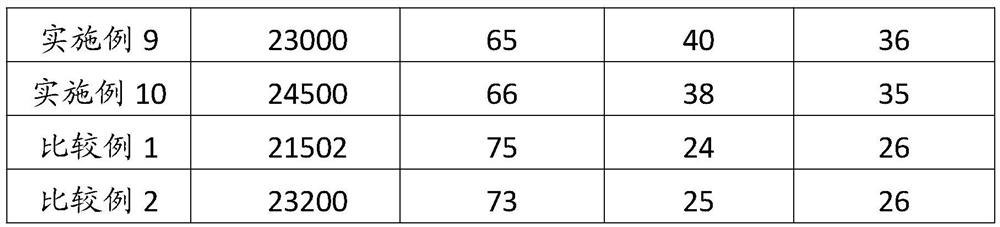

[0060] See Table 1 for the water seepage rate of the system, the apparent temperature of the turf, and the frictional force between the rec...

Embodiment 2

[0062] Recyclable artificial turf layer 1: the back is non-woven hot-melt adhesive artificial turf, the row spacing is 5 / 8, the number of stitches is 16 stitches, the grass height is 40mm, and the lawn weight is 1kg / m 2 ;

[0063] Damping cloth layer 2: The weight of non-woven fabric is 300g / m 2 , PVC double-sided point plastic weight 130g / m 2 , the density of spot molding is 30,000 pieces / m 2 .

[0064] Elastic cushion layer 3: 3D silk cushion layer with a thickness of 15mm. After mixing 80kg copolymerized PP, 14kg polyethylene, 4kg color masterbatch and 2 parts of stabilizing additives, it is extruded through a single-screw extruder, and extruded through a spinneret die. Out of the cooling water to cool and shape, the 3D is solid, and the diameter of the 3D wire is 1.5mm.

[0065] Water storage tank 4: The depth of the water storage tank is 20mm.

[0066] See Table 1 for the water seepage rate of the system, the apparent temperature of the turf, and the frictional force...

Embodiment 3

[0068] Recyclable artificial turf 1: The back is non-woven hot-melt adhesive artificial turf, the row spacing is 5 / 8, the number of stitches is 16, the grass height is 40mm, and the lawn weight is 1kg / m 2 ;

[0069] Damping cloth layer 2: The weight of non-woven fabric is 300g / m 2 , PVC double-sided point plastic weight 130g / m 2 , the density of spot molding is 30,000 pieces / m 2 .

[0070] Elastic cushion layer 3: 3D silk cushion layer, thickness 20mm, 80kg copolymerized PP, 14kg ethylene-octene copolymer, 4kg color masterbatch, 2 parts of stabilizing agent are mixed and extruded through a single-screw extruder. The plate die head is extruded with cooling water to cool and shape, and the 3D wire is hollow with a diameter of 1.5mm.

[0071] Water storage tank 4: The depth of the water storage tank is 20mm.

[0072] See Table 1 for the water seepage rate of the system, the apparent temperature of the turf, and the frictional force between the recyclable artificial turf and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com