Blasting blocking dust fall device

A technology of resistance drop and blast holes, which is applied in blasting, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as no buffering of blasting impact force, small range of water curtain, excessive dust concentration, etc., and achieve tight sealing of blast holes , Saving natural resources, the effect of increasing the range of water curtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

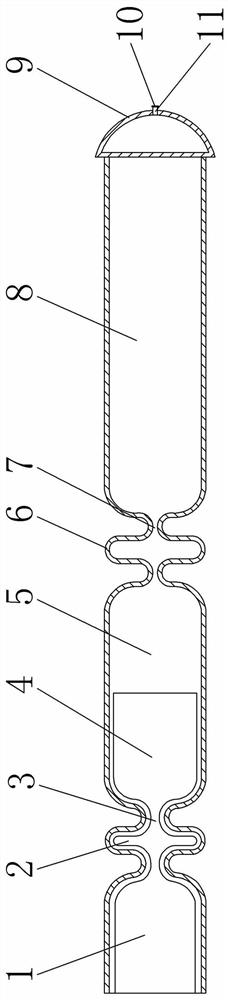

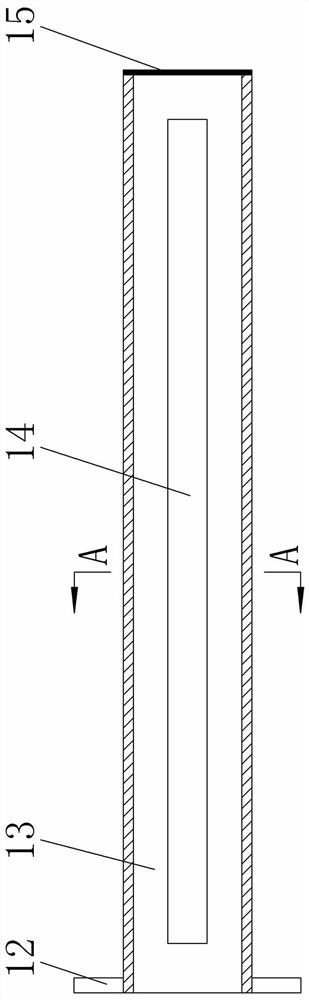

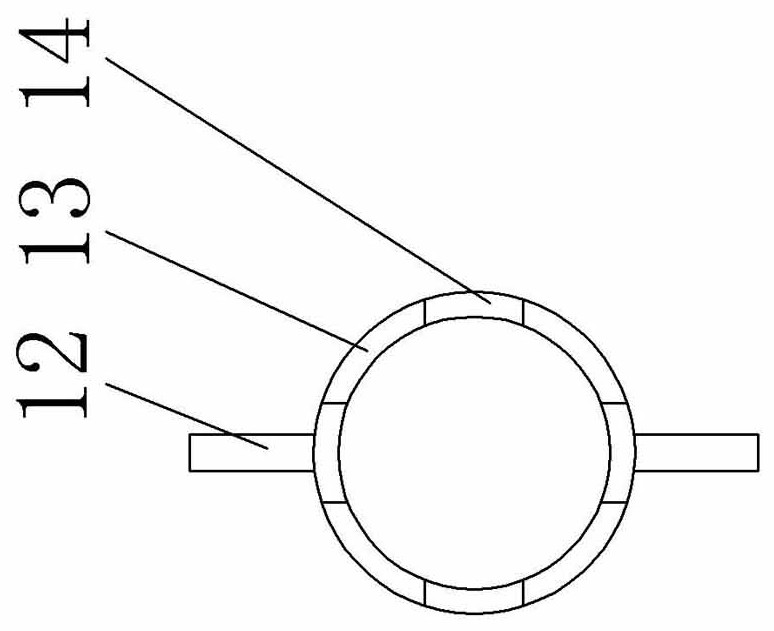

[0012] The specific embodiment of the present invention is, with reference to figure 1 , including the blister bag body and special tools for the blister bag, the blister bag body has a water injection cavity 1, a water injection channel cavity 2, a water injection channel 3, a water injection channel sealing bag layer 4, a section of blister bag 5, a water bag partition cavity 6, and a high-pressure water channel 7. The second-stage blister bag 8, the air bag 9 at the end of the blister bag and the air nozzle 11, wherein, there is a water injection channel cavity 2 between the water injection chamber 1 and the first-stage blister bag 5, and the water injection channel 3 is connected to the water injection chamber 1 and the first-stage blister bag. The blister bags 5 are connected, and the first section of the blister bag 5 has a water injection channel sealing bag layer 4. There is a water bag partition 6 between the first section of the blister bag 5 and the second section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com