Plastic film residue winding device and combined machine formed by same and plastic film residue bundling method of combined machine

A combined operation machine and residual film technology, which is applied in collectors, agricultural machinery and tools, agriculture, etc., can solve the problems of secondary pollution, unsuitable storage and transportation of recycled plastic film, etc., achieve good operating performance, improve work efficiency and be economical and practical Sexuality, enhance the effect of comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

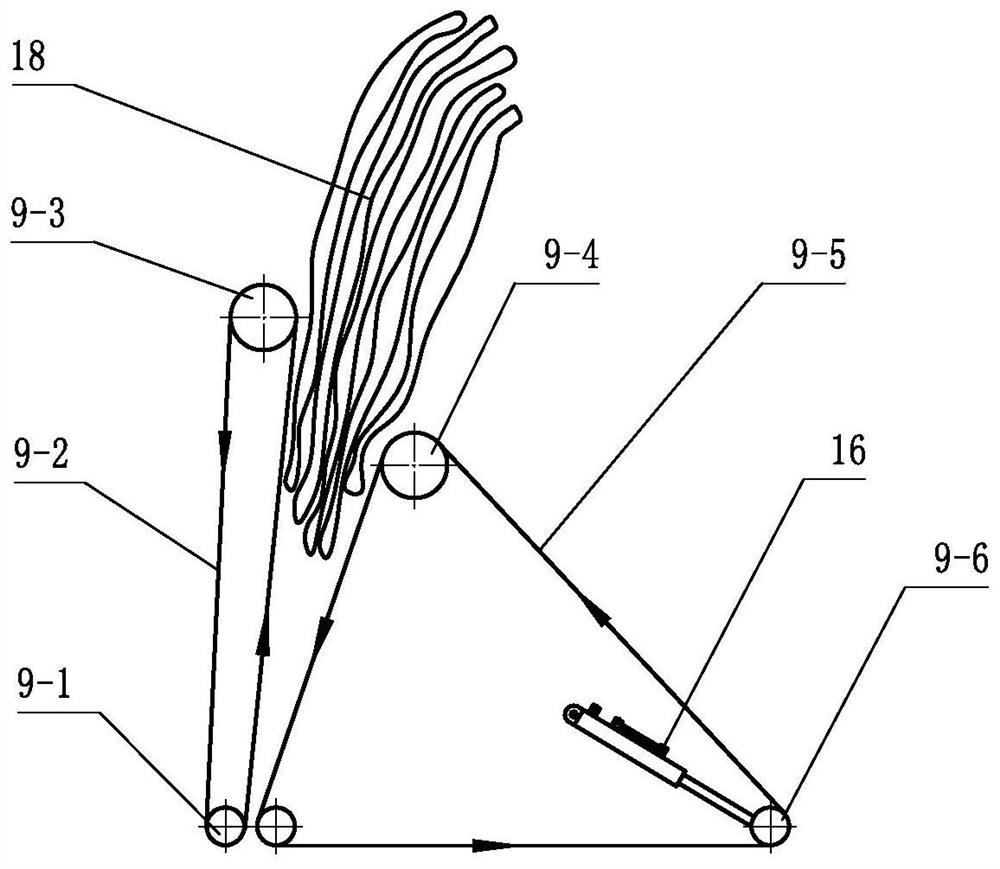

[0036] Embodiment 1: refer to Figure 3-4 , is a schematic structural diagram of Embodiment 1 of the present invention,

[0037] A residual film retracting device, comprising a residual film bundling mechanism 9, the residual film bundling mechanism 9 includes a front driving roller shaft 9-3, a front auxiliary roller shaft 9-1, a front belt 9-2, and a rear driving roller Shaft 9-4, rear auxiliary roller shaft 9-6, rear belt 9-5, the front belt 9-2 is arranged on the front driving roller shaft 9-3 and the front auxiliary roller shaft 9-1, the rear belt 9 -5 is arranged on the rear driving roller shaft 9-4 and the rear auxiliary roller shaft 9-6, and the rotation directions of the front driving roller shaft 9-3 and the rear driving roller shaft 9-4 are the same, and the front driving roller shaft 9-3. The two ends of the rear driving roller shaft 9-4, the front auxiliary roller shaft 9-1 and the rear auxiliary roller shaft 9-6 are all installed on the frame 2 through bearings,...

Embodiment 2

[0040] Embodiment 2: refer to Figure 5 with Image 6 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that there are four rear auxiliary roller shafts 9-6, and the rear auxiliary roller shaft 9-6 with hydraulic cylinder II16 6 is located outside the space enclosed by the rear belt 9-5.

Embodiment 3

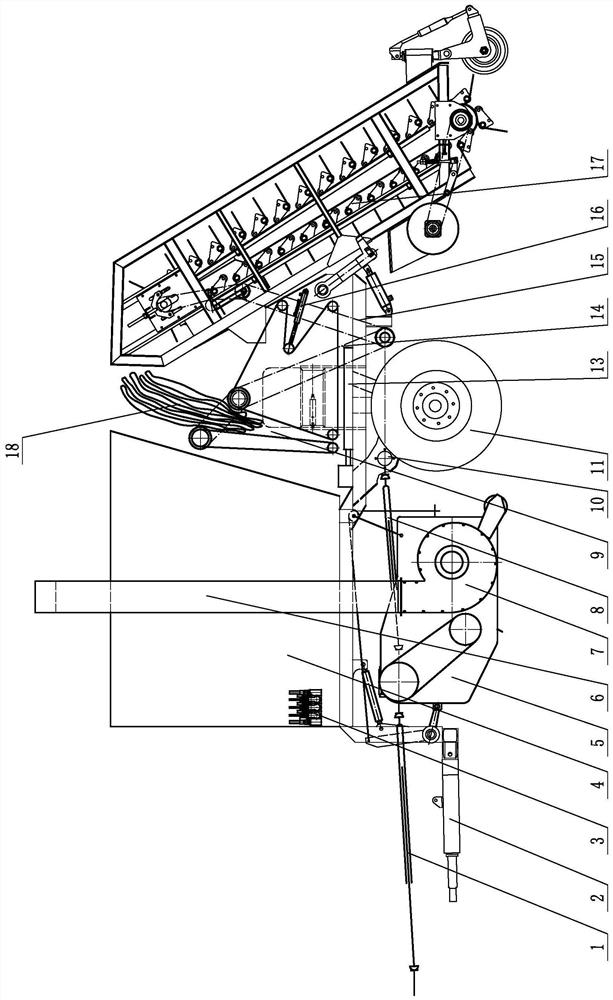

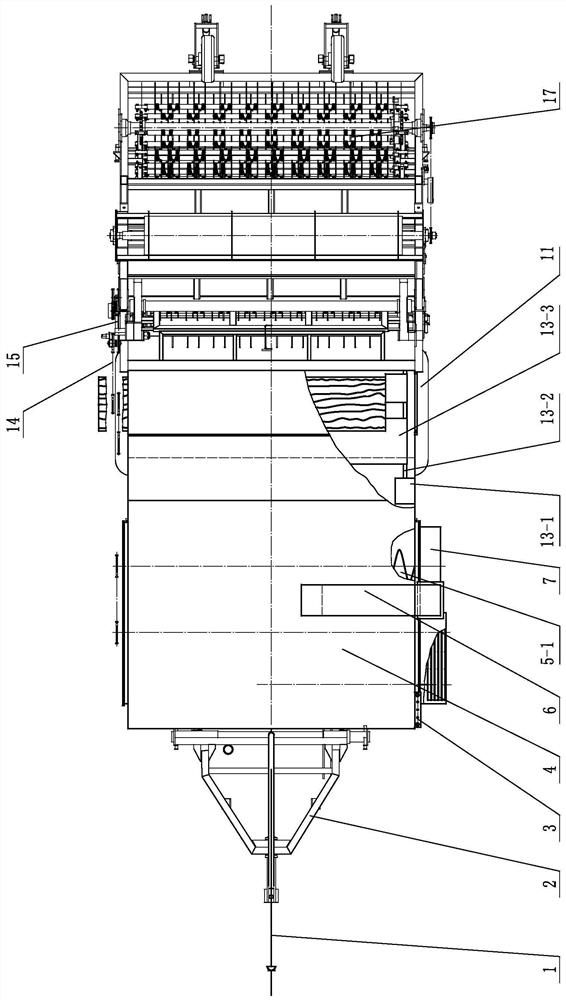

[0041] Embodiment 3: refer to figure 1 with figure 2 , is a schematic structural diagram of Embodiment 3 of the present invention,

[0042] A combined operating machine for residual film rolling and straw crushing and collection, comprising a frame 2, a transmission system, a hydraulic system, and a walking mechanism 11 arranged on the frame 2. The frame 2 is provided with a straw crushing and collecting device, a residual A film bundling mechanism 9, a film unloading mechanism 13 and a residual film picking device 17, the straw pulverizing and collecting device is arranged at the front end of the frame 2, and a residual film bundling mechanism 9 is provided behind the straw pulverizing and collecting device. The film unloading mechanism 13 is arranged below the residual film bundling mechanism 9, and the rear side of the residual film bundling mechanism 9, that is, the rear end of the frame 2, is provided with a residual film picking device 17, wherein:

[0043] The transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com