Combined stirring blade metal core for molten iron KR desulfurization stirrer

A stirrer and combined technology, which is applied in the field of combined stirring blade metal cores for molten iron KR desulfurization stirrers, can solve the problems of long custom processing cycle for anchor bricks, reduce online maintenance and repair, and restrict industrial implementation, etc., and achieve simple processing and preparation Reliable, reduce online maintenance amount and maintenance cost, and delay the effect of online start maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

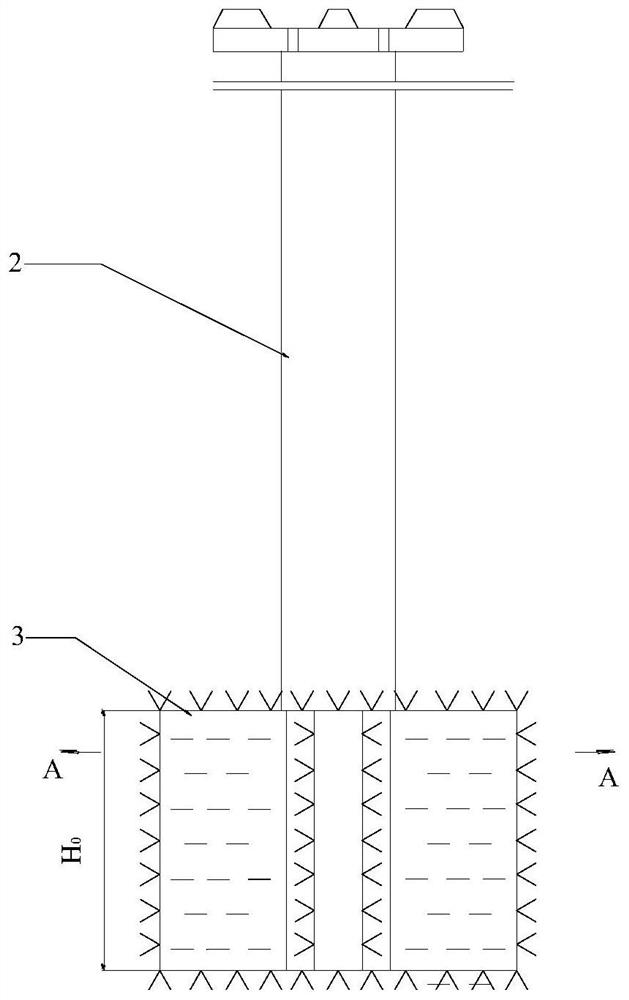

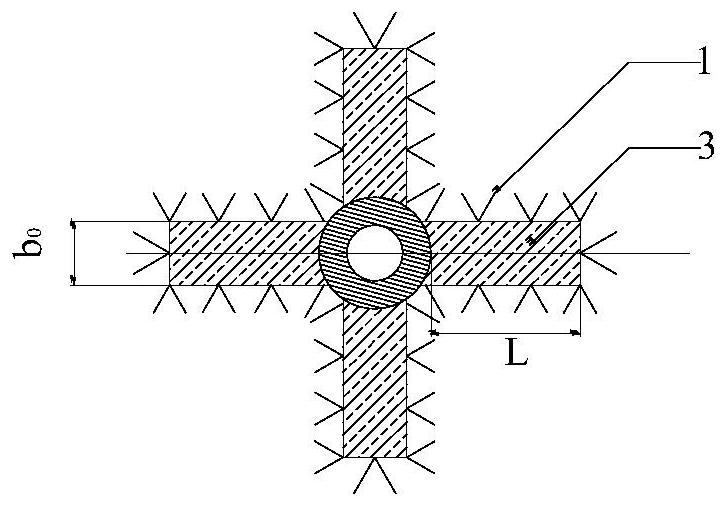

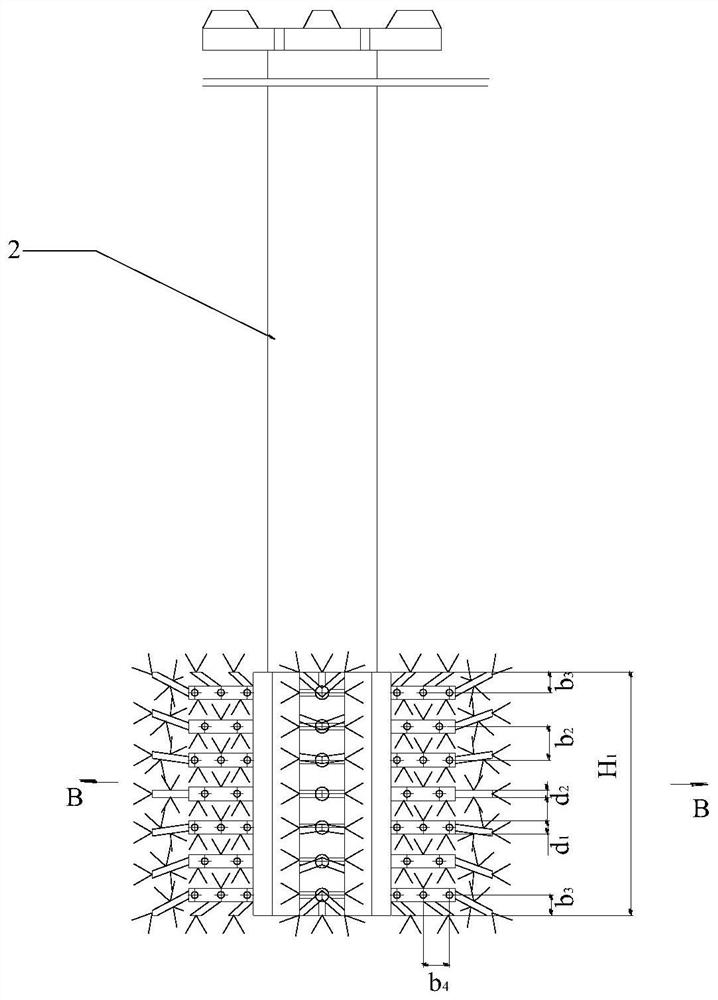

[0024] like figure 1 , 2 shown as image 3 , 4 The shown combined type stirring blade metal core for molten iron KR desulfurization stirrer includes three or four rectangular metal thick plates 4, several large-diameter metal round rods 5 mounted on each rectangular metal thick plate 4, and Several small-diameter metal round rods 6 on the large-diameter metal round rods 5, wherein three or four rectangular metal thick plates 4 are evenly arranged in the circumferential direction and the inner side of the rectangular metal thick plates 4 is connected to the metal stirring shaft core 2. The outer surface of the lower part is welded, and several large-diameter metal round rods 5 are welded on the outer side of the rectangular metal thick plate 4 in a single row along the axial direction of the stirrer, and each large-diameter metal roun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap