A kind of dismantling-free cleaning device, cleaning method and application of bearing seat of cold rolling mill

A technology for cleaning device and bearing seat, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of stable and direct rolling mill production, low qualification rate, long consumption time, etc. Achieve the effect of reducing the content of chemical components, avoiding manual disassembly and assembly, and reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

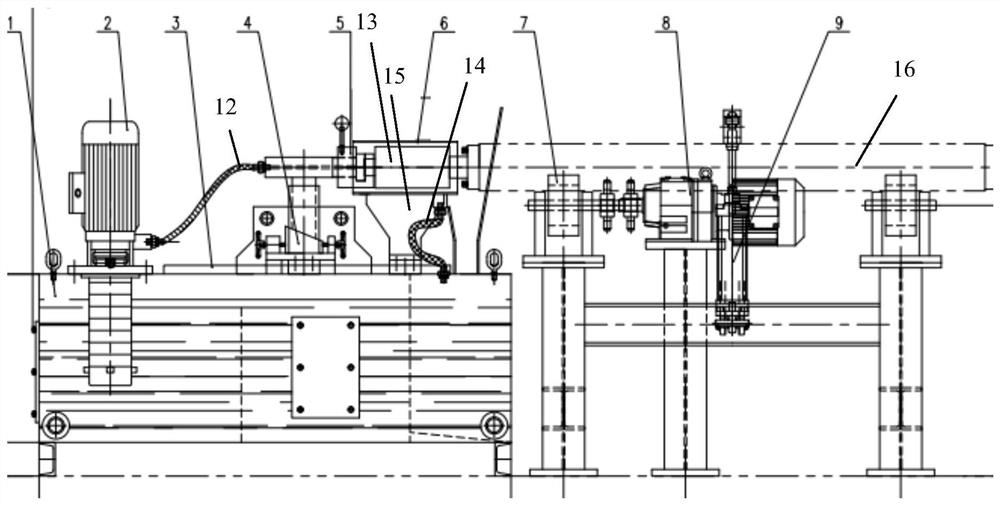

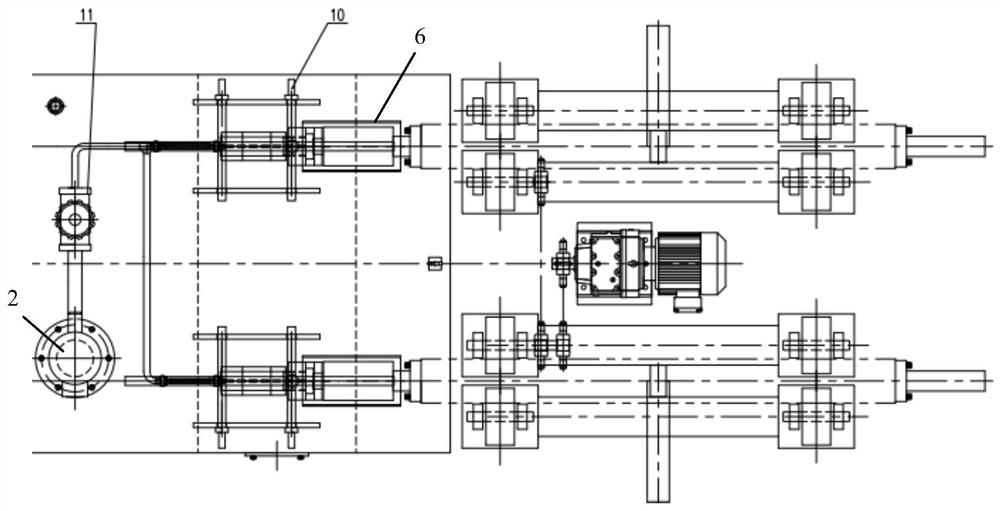

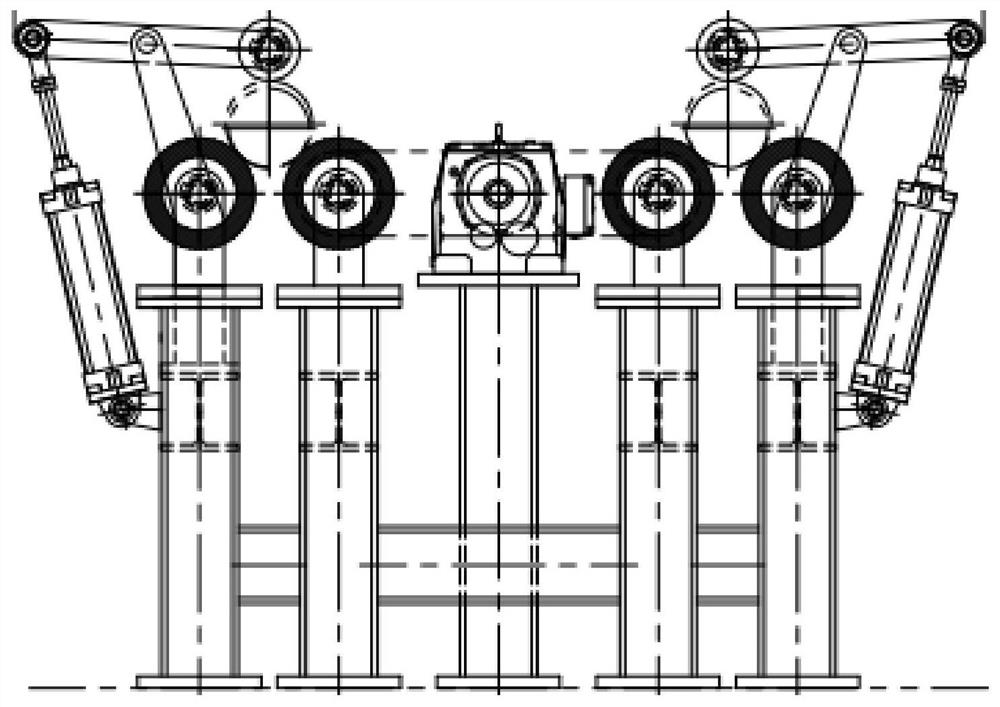

[0081] Cold rolling 20-high single-stand reversible rolling mill, there are 4 middle rolls in the whole roll system. During the whole process of rolling plate shape control, through the movement of a middle roll, the 1 / 4 of the curling part of the plate will be waved. to the flattening effect. Each intermediate roller is equipped with a bearing seat on one side, and the internal structure of the bearing seat mainly includes thrust bearings, radial bearings, gap rings and other components.

[0082] The current cleaning and maintenance content of an intermediate roller bearing housing is as follows:

[0083] 1. When the maintenance cycle of the bearing in the bearing seat is up (150 hours online), it needs to be manually disassembled, disassembled, cleaned and maintained;

[0084] 2. For an intermediate bearing seat that got off the machine in an accident (such as stacked steel, broken strips and sticky steel, etc.), it needs to be manually disassembled, disassembled, cleaned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com