Acoustic emission monitoring and endpoint for chemical mechanical polishing

A chemical machinery and grinding pad technology, applied in grinding machine tools, grinding tools, grinding devices, etc., can solve the problem of unable to meet the increasing demand of semiconductor device manufacturers, and achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

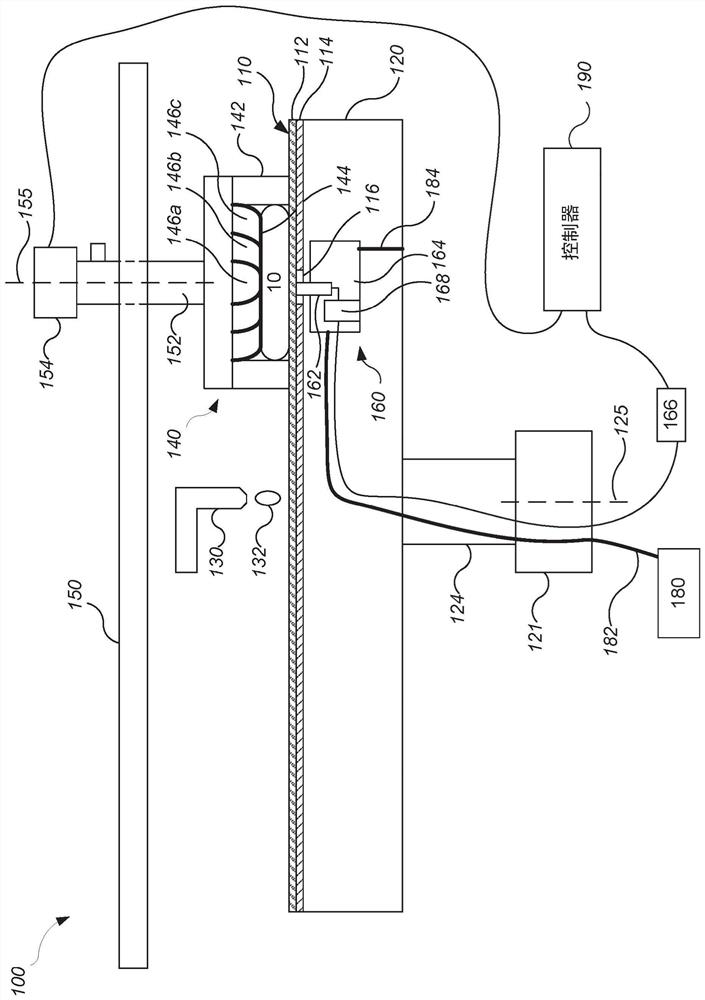

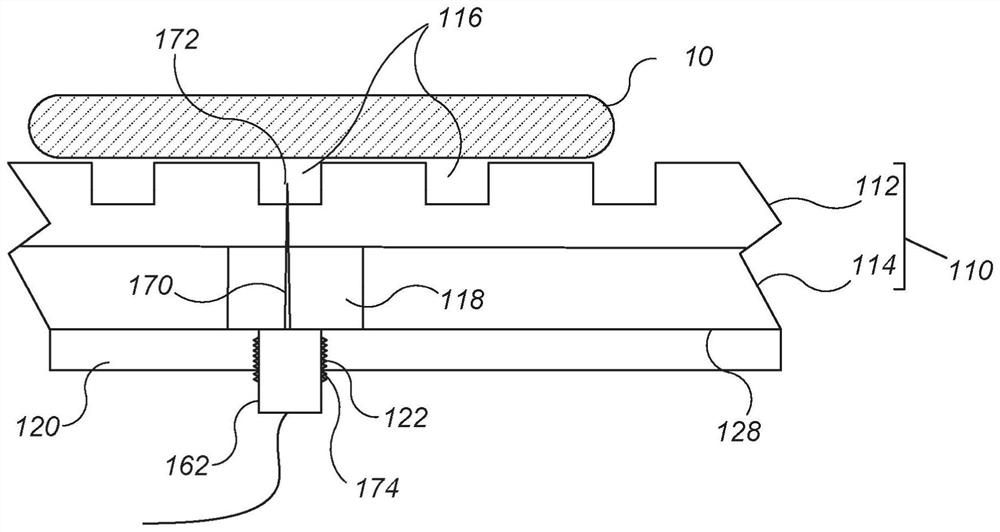

[0031] In some semiconductor chip fabrication processes, overlying layers (eg, metal, silicon oxide, or polysilicon) are ground until underlying layers (eg, dielectrics such as silicon oxide, silicon nitride, or high-K dielectrics) are exposed. For some applications, the acoustic emission from the substrate will change when the undercoat is exposed. The end of grinding can be determined by detecting this change in the acoustic signal.

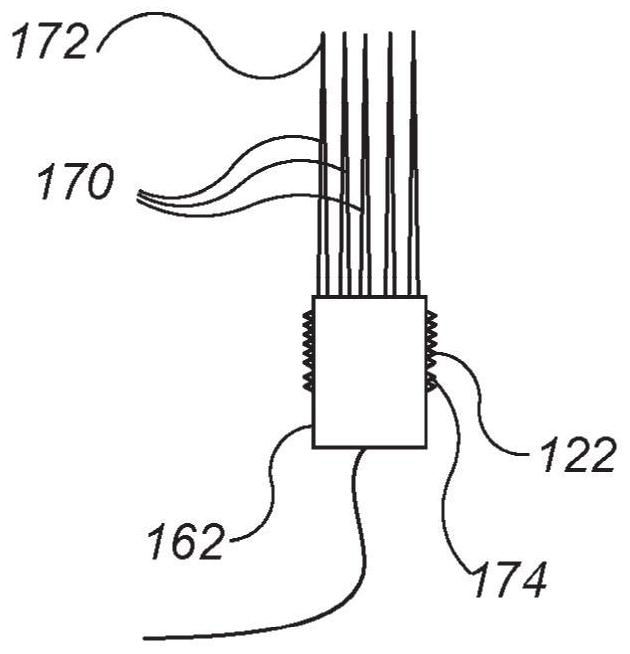

[0032] The acoustic emission to be monitored may be caused by stress energy when the substrate material is deformed, and the resulting acoustic spectrum is related to the material properties of the substrate. It may be noted that this acoustic effect is not the same as the noise (sometimes referred to as the acoustic signal) produced by the substrate rubbing against the polishing pad; the acoustic effect occurs in a significantly higher frequency range than such rubbing noise, e.g., 50kHz to 1 MHz, and thus the monitoring of a suitable frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com