Preparation method of two-dimensional graphdiyne nanosheet, working electrode, and photoelectric detector

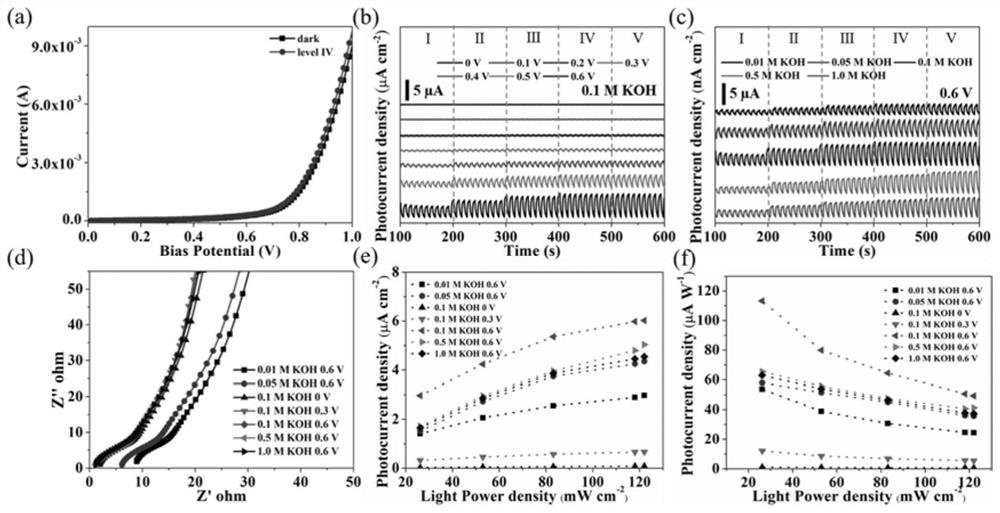

A working electrode and graphdiyne technology, applied in two-dimensional nanomaterials and their application fields, can solve the problems of inability to have high carrier mobility bandgap, flexibility, and difficulty in effectively batch preparation of two-dimensional graphdiyne nanosheets, etc. Achieve excellent photoelectric detection performance, broaden the scope of use, and ensure the effect of work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

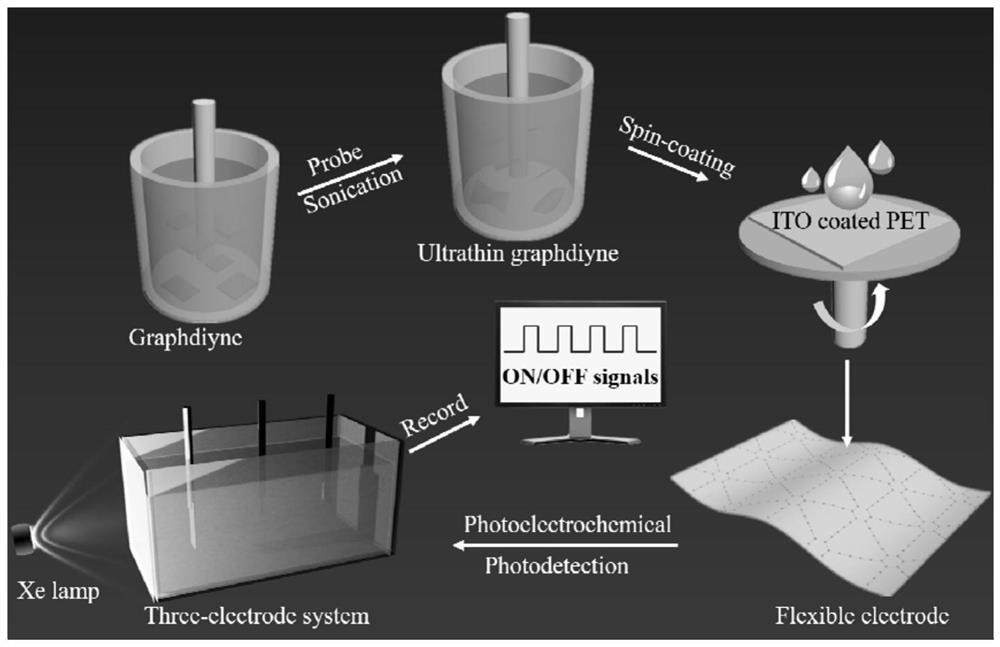

[0033] In a first aspect, the invention provides a method for preparing two-dimensional graphyne nanosheets, comprising the following steps:

[0034] Provide an ethanol dispersion of graphyne, transfer the ethanol dispersion of graphyne to 2 to 15°C for ultrasonication for 1 to 7 days, separate the ethanol dispersion of graphyne after ultrasonication by stepwise centrifugation, and collect The graphyne nanosheets obtained at 5,000-8,000 r / min are dried to prepare two-dimensional graphyne nanosheets.

[0035] Preferably, the ethanol dispersion of the graphyne is prepared by the following method: providing the graphyne block powder dispersed in ethanol, the ratio of the mass of the graphyne block powder to the mass of ethanol is 1:16~400, the preparation Obtain the ethanol primary dispersion liquid of graphyne;

[0036] Stir the ethanol primary dispersion of the graphyne for 10-100 min to prepare the ethanol dispersion of the graphyne.

[0037] Optionally, the ratio of the mas...

Embodiment 1

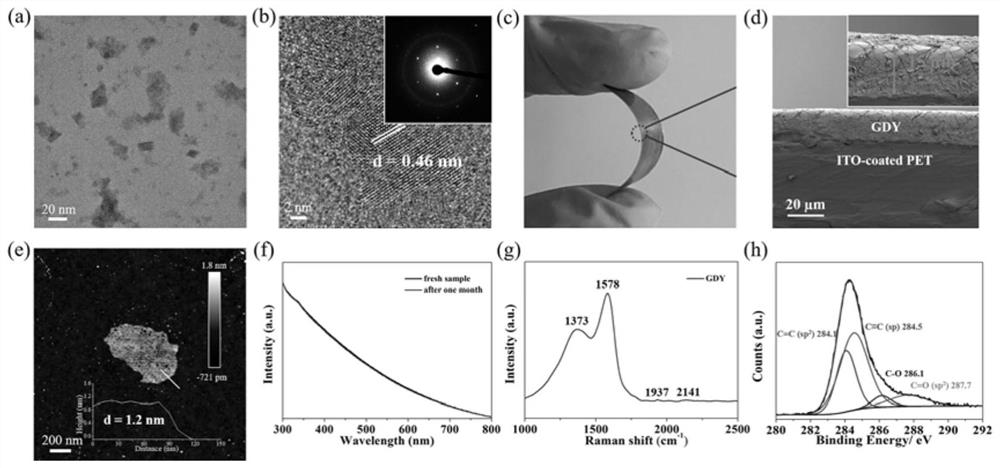

[0052] A kind of preparation method of two-dimensional ultrathin graphyne nanoplate comprises the following steps:

[0053] Step 1: Provide 1 mg of graphyne bulk powder and disperse it in 100 mL of ethanol, mix and stir for 30 minutes, and the stirring speed is 350 rpm to prepare the ethanol dispersion of graphyne

[0054] Step 2: Transfer the ethanol dispersion of graphdiyne to a water bath environment at 8°C, and ultrasonicate the water bath for 4 days.

[0055] Step 3: The ethanol dispersion of the graphyne after ultrasonication in a water bath is separated using a stepwise centrifugation method, the initial centrifugal speed is 3000r / min, centrifuged for 5min, and then the precipitate under the centrifugal condition of 3000r / min is collected; press each time 1000r / min The speed of min gradually increases the rotation speed, and at the same time collects the corresponding precipitate at this rotation speed, thereby obtaining graphdiyne nanosheets with different thicknesses....

Embodiment 2

[0059] A kind of preparation method of two-dimensional ultrathin graphyne nanoplate comprises the following steps:

[0060] Step 1: Provide 1 mg of graphyne bulk powder and disperse it in 500 mL of ethanol, mix and stir for 10 minutes, and the stirring speed is 500 rpm to prepare the ethanol dispersion of graphyne

[0061] Step 2: Transfer the ethanol dispersion of graphdiyne to a water bath environment at 15°C, and ultrasonicate the water bath for 1 day.

[0062] Step 3: The ethanol dispersion of the graphyne after ultrasonication in a water bath is separated using a stepwise centrifugation method, the initial centrifugal speed is 4000r / min, centrifuged for 5min, and then the precipitate under the centrifugal condition of 4000r / min is collected; The speed of min gradually increases the rotation speed, and at the same time collects the corresponding precipitate at this rotation speed, thereby obtaining graphdiyne nanosheets with different thicknesses.

[0063] Step 4: Collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com