Glass fiber modified polypropylene with high impact resistance and high modulus and preparation method thereof

A technology of glass fiber and high modulus, which is applied in the field of polypropylene and its composition, can solve the problem that the impact and other mechanical properties of glass fiber modified polypropylene cannot be improved at the same time, and achieve the goal of improving impact performance and impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

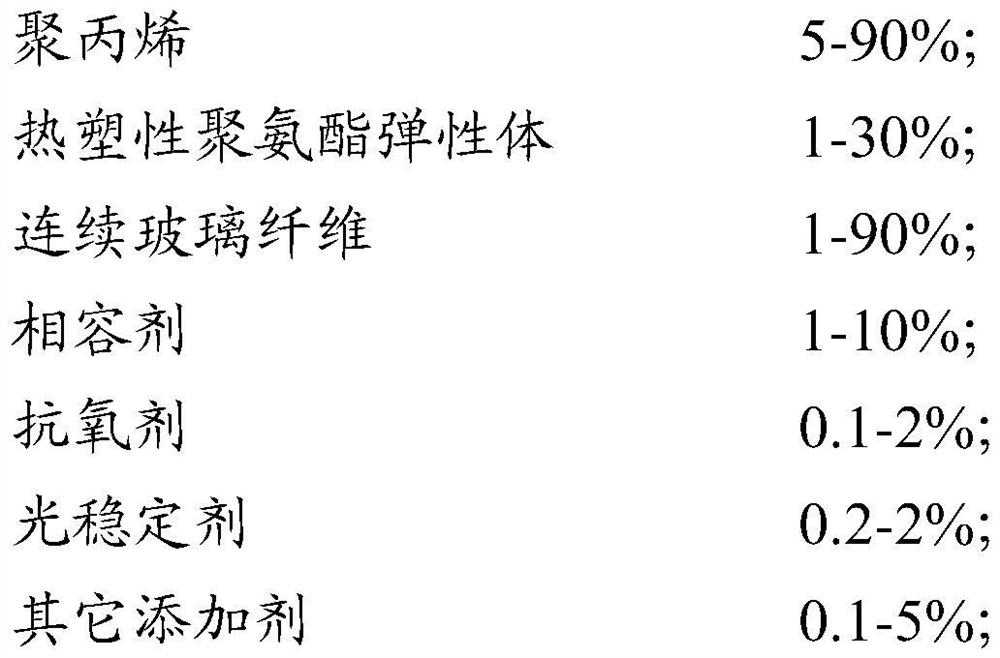

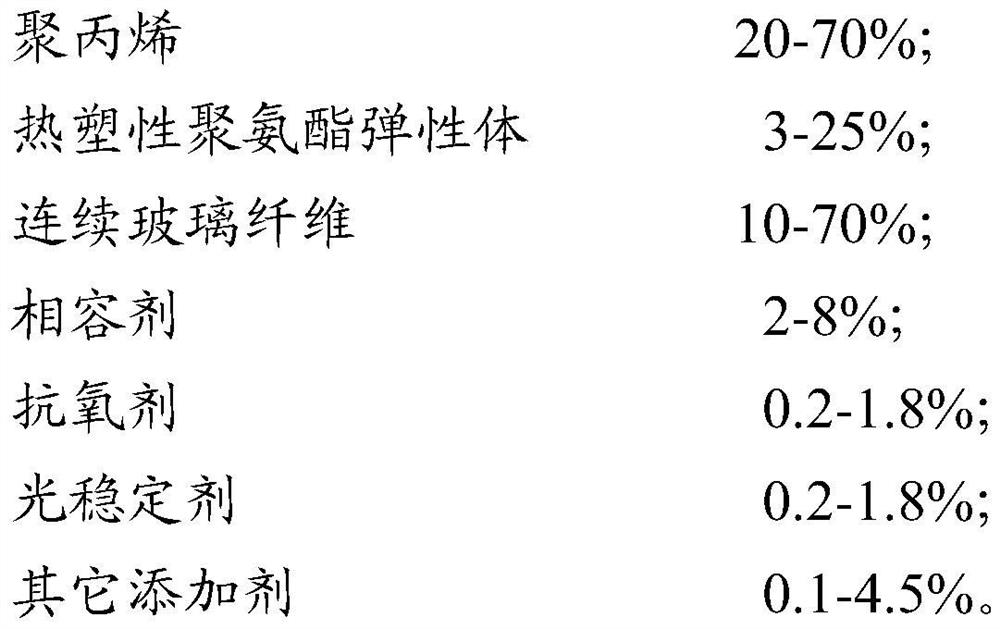

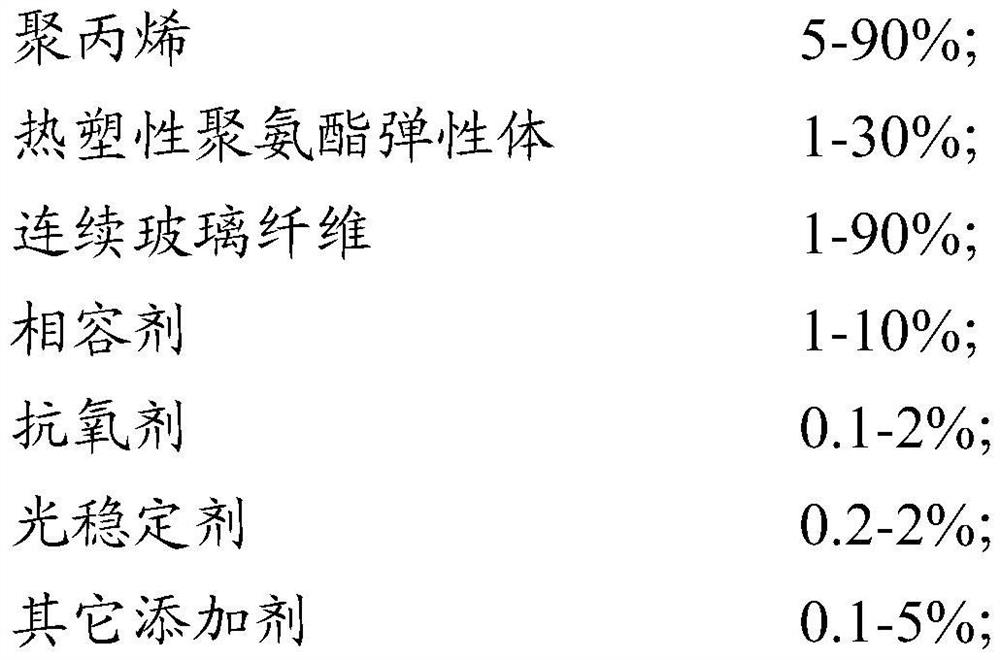

Method used

Image

Examples

Embodiment 1

[0052] (1) Weigh 5wt.% of thermoplastic polyurethane elastomer, 0.2wt.% of primary antioxidant, and 0.1wt.% of secondary antioxidant, put them in a high-speed mixer and mix for 5 minutes to obtain mixture one; It is melted and plasticized in a twin-screw extruder at 120°C for 1 min. The plasticized melt is fully infiltrated with the continuous glass fiber through the long glass fiber infiltration die. The infiltrated continuous glass fiber is cooled under cold air, fully dried, and then collected. volume;

[0053] (2) Weigh 66.8wt.% polypropylene, 15wt.% polyolefin elastomer (brand 8150, Dow), 2wt.% compatibilizer, 0.1wt.% primary antioxidant, 0.1wt.% The auxiliary antioxidant, 0.2wt.% light stabilizer, and 0.5wt.% lubricant were mixed to obtain the second mixture, which was mixed and added to the single-screw extruder for melting and plasticization, and the melting and plasticization temperature was 190 ~220℃, plasticizing time 2min;

[0054] After fully melted and plasticized, ...

Embodiment 2

[0056] (1) Weigh 10wt.% of thermoplastic polyurethane elastomer, 0.2wt.% of primary antioxidant, and 0.1wt.% of secondary antioxidant, put them in a high-speed mixer and mix for 5 minutes to obtain mixture one; It is melted and plasticized in a twin-screw extruder at 120°C for 1 min. The plasticized melt is fully infiltrated with the continuous glass fiber through the long glass fiber infiltration die. The infiltrated continuous glass fiber is cooled under cold air, fully dried, and then collected. volume;

[0057] (2) Weigh 51.8wt.% polypropylene, 15wt.% polyolefin elastomer (brand 8150, Dow), 2wt.% compatibilizer, 0.1wt.% primary antioxidant, 0.1wt.% The auxiliary antioxidant, 0.2wt.% light stabilizer, and 0.5wt.% lubricant were mixed to obtain the second mixture, which was mixed and added to the single-screw extruder for melting and plasticization, and the melting and plasticization temperature was 190 ~220℃, plasticizing time 2min;

[0058] After being fully melted and plasti...

Embodiment 3

[0060] (1) Weigh 15wt.% of thermoplastic polyurethane elastomer, 0.2wt.% of primary antioxidant, and 0.1wt.% of secondary antioxidant, put them in a high-speed mixer and mix for 5 minutes to obtain mixture one; It is melted and plasticized in a twin-screw extruder at 120°C for 1 min. The plasticized melt is fully infiltrated with the continuous glass fiber through the long glass fiber infiltration die. The infiltrated continuous glass fiber is cooled under cold air, fully dried and then collected volume;

[0061] (2) Weigh 46.8wt.% polypropylene, 15wt.% polyolefin elastomer (brand 8150, Dow), 2wt.% compatibilizer, 0.1wt.% primary antioxidant, 0.1wt.% The auxiliary antioxidant, 0.2wt.% light stabilizer, and 0.5wt.% lubricant were mixed to obtain the second mixture, which was mixed and added to the single-screw extruder for melting and plasticization, and the melting and plasticization temperature was 190 ~220℃, plasticizing time 2min;

[0062] After being fully melted and plastici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com