Shield launching flexible connecting steel sleeve mechanism and construction method thereof

A flexible connection and steel sleeve technology, which is applied in wellbore lining, earthwork drilling, tunnel lining, etc., can solve problems such as damage and failure of steel sleeve reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below the present invention is further described:

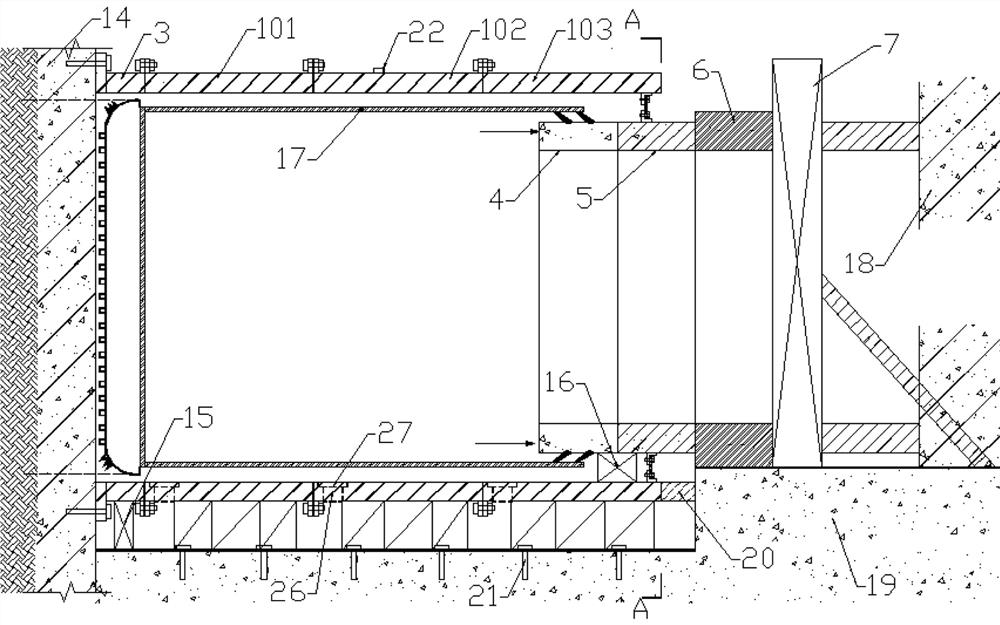

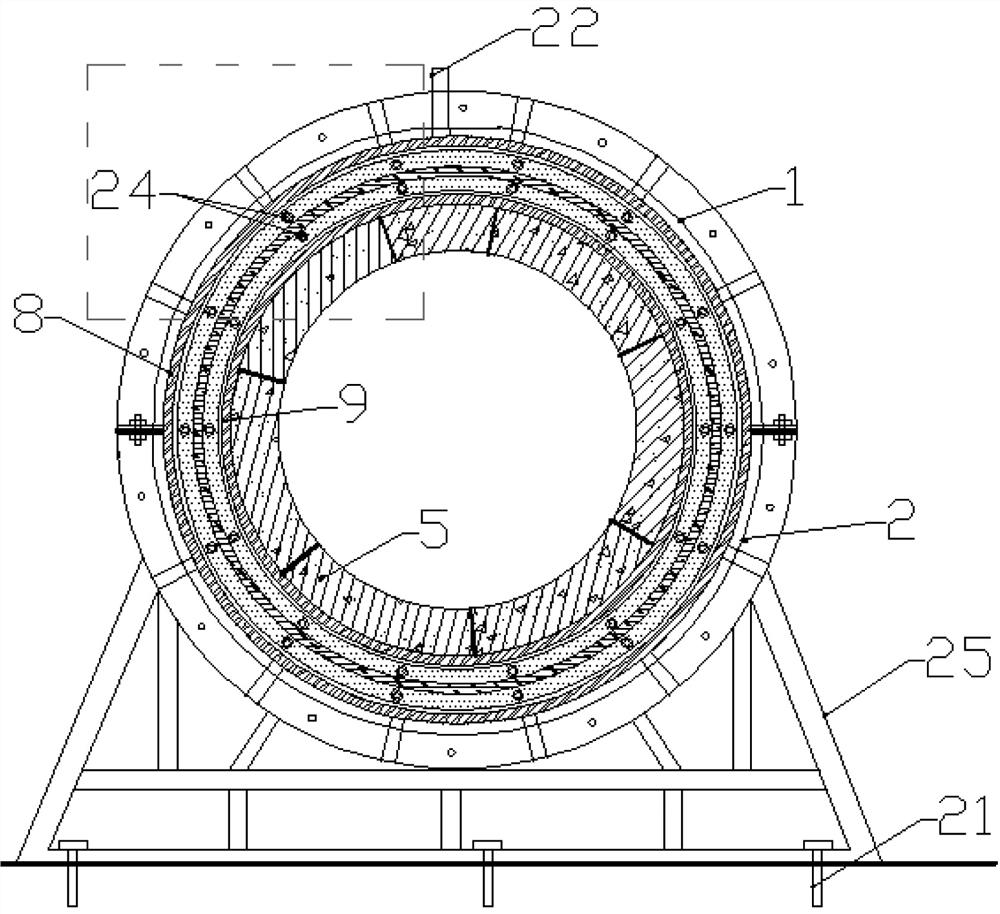

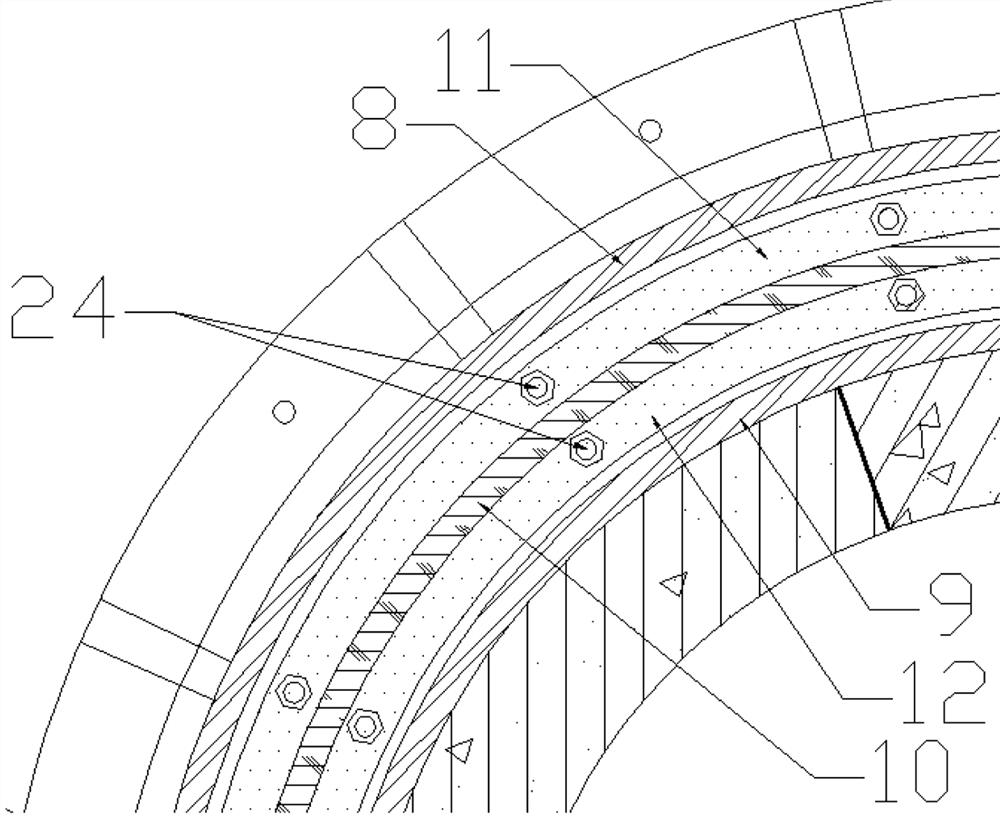

[0053] see Figure 1-6 ,

[0054] The invention discloses a flexible connecting steel sleeve mechanism for shield tunneling, which includes a steel sleeve body used to cover a shield machine 22, an annular transition steel ring 3, a negative ring segment 4, a special segment 5, and a reinforcing ring Beam 6, reaction frame 7;

[0055] The annular transition steel ring 3 has an annular structure, one end of which is connected to the ground wall 14, and the other end is connected to the front end of the steel sleeve body;

[0056] The steel sleeve body is composed of a first steel sleeve unit 101, a second steel sleeve unit 102 and a third steel sleeve unit 103 connected in sequence along its axial direction, the second steel sleeve unit 102 The outer wall is provided with a grouting nozzle 22; the steel sleeve body is formed by butting and combining a semicircular upper steel cylinder 1 and a lower steel cylinder 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com