Phase-change heat-storage medium melting device and system

A phase change heat storage and melting device technology, applied in heat storage equipment, energy storage, indirect heat exchangers, etc., can solve the problems of high production cost, large gas consumption, gas environmental protection, etc., to save production costs and improve mixing effect, the effect of improving melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

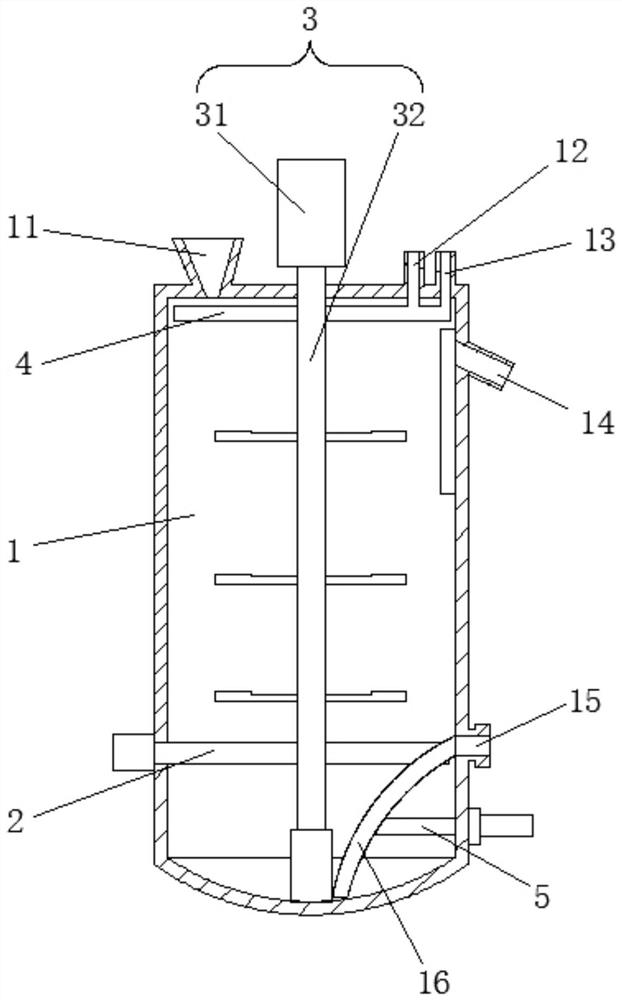

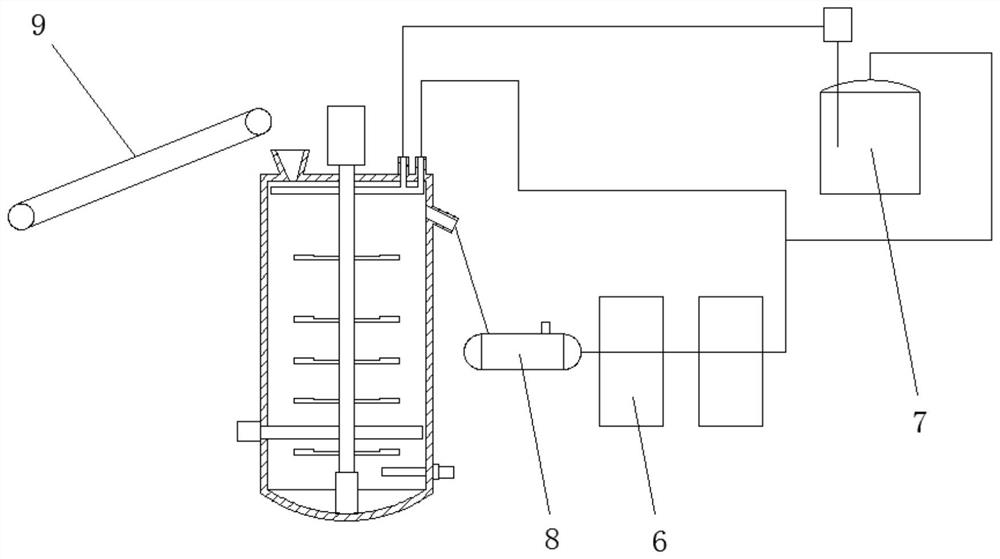

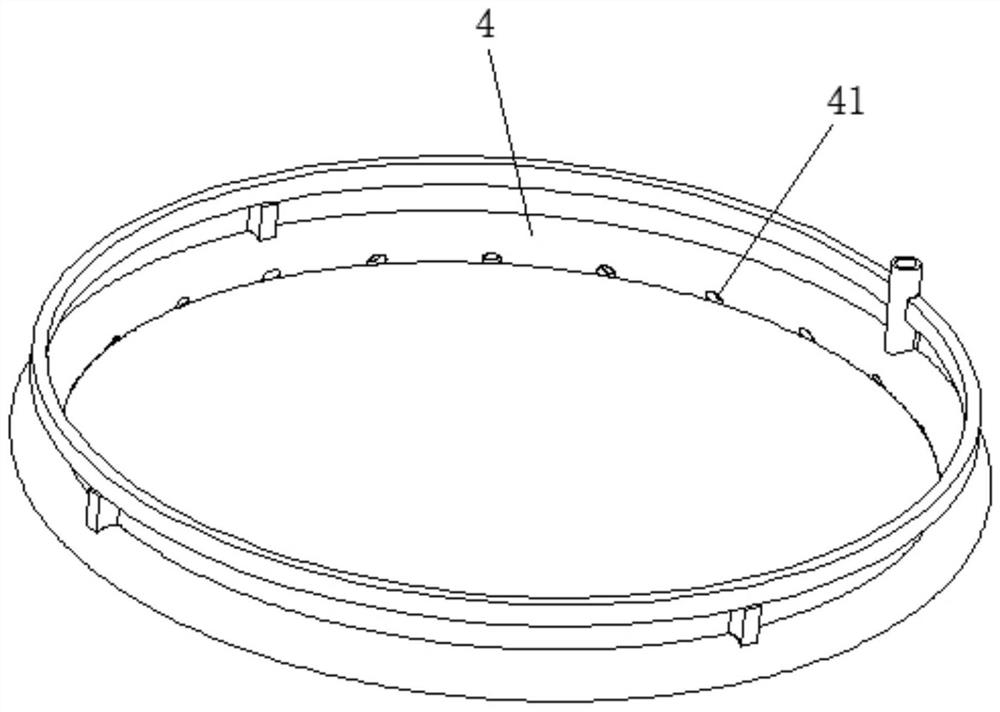

[0030] See figure 1 , the phase-change heat storage medium melting device in the present invention includes a thermal insulation container 1; the thermal insulation container 1 is provided with an inlet 11 for a solid phase-change heat storage medium to enter, and an inlet 11 for a liquid phase-change heat storage medium Outflow overflow port 14; the heat preservation container 1 is provided with a group of heating tubes 2 for circulating combustion gas; the exhaust port of the heating tube group 2 extends out of the heat preservation container 1; the heat preservation container 1 is provided with an agitator 3 The driving device 31 of the agitator 3 is fixedly arranged on the top of the heat-retaining container 1, and the stirring shaft 32 of the agitator 3 stretches into the heat-retaining container 1; the heating tube group 2 is arranged at the bottom of the heat-retaining container 1; There are two inlets for the liquid phase-change heat storage medium to flow in, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com