Butt welding method and welding structure of bimetal clad plate without intermediate layer

A welding method and composite plate technology, applied in welding equipment, metal processing equipment, laser welding equipment, etc., can solve the problems of deterioration of corrosion resistance of stainless steel layer, influence of mechanical properties of brittle compounds, poor welding quality, etc., and achieve stable joint performance , low cost, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

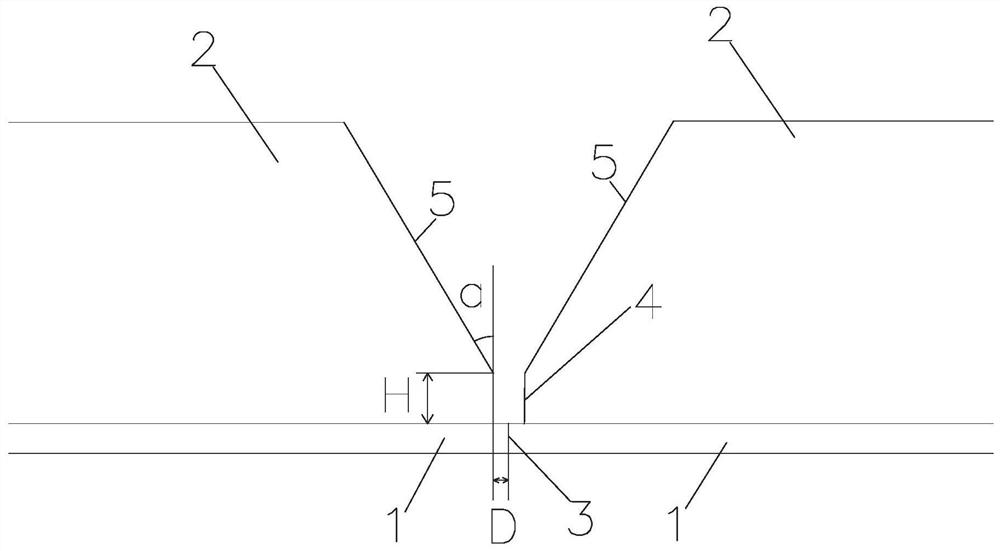

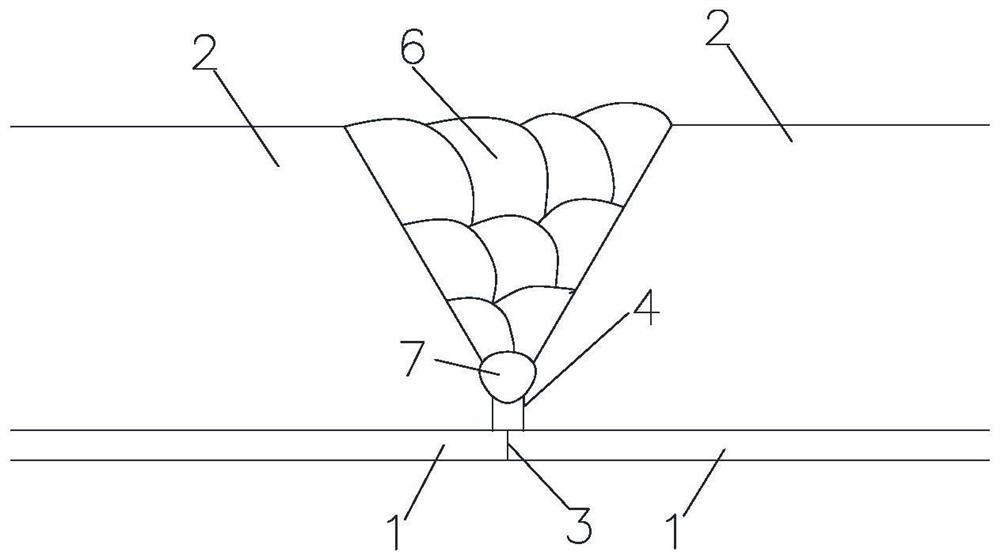

[0027] The titanium / steel clad plate is welded by adopting the butt welding structure and the welding method of the bimetal clad plate proposed by the present invention. Wherein, the material of the composite layer (1) is TC4 titanium alloy, and the material of the base layer (2) is X80 pipeline steel. The thickness of the composite layer is 1mm; the thickness of the base layer is 18mm.

[0028] The welding procedure includes the following steps:

[0029] a. First use the milling method to mill the welded end face of the plate. Align and close them together, and check with a feeler gauge, the gap between the two plates is less than 0.1mm. Then, the X80 steel material with a thickness of 1.2 mm is removed from the end face to be welded by milling, and the titanium layer is retained; at this time, the titanium layer is a step of 1.2 mm protruding from the base layer. Then use the milling method to open the groove of the base material, the groove angle is 30° on one side, and ...

Embodiment 2

[0035] The titanium / steel clad plate is welded by adopting the butt welding structure and the welding method of the bimetal clad plate proposed by the present invention. The composite layer material is TA1 pure titanium, and the base layer material is Q235 steel. The thickness of the composite layer is 0.8mm; the thickness of the base layer is 6mm.

[0036] The welding procedure includes the following steps:

[0037] a. First use the milling method to mill the welded end face of the plate. Align and close them together, and check with a feeler gauge, the gap between the two plates is less than 0.1mm. Then, the Q235 steel material with a thickness of 1 mm is cut off on the end face to be welded by milling, and the titanium layer is retained; at this time, the titanium layer is a step of 1 mm protruding from the base layer. Then use the milling method to open the groove of the base layer, the angle of which is 30° on one side, and the thickness of the blunt edge is 2mm;

[0...

Embodiment 3

[0043]The stainless steel / carbon steel clad plate is welded by adopting the butt welding structure and the welding method of the bimetal clad plate proposed by the present invention. The composite layer material is SUS316L stainless steel, and the base layer material is Q235 steel. The thickness of the composite layer is 1mm; the thickness of the base layer is 8mm. The welding procedure includes the following steps:

[0044] a. First use the milling method to mill the welded end face of the plate. Align and close them together, and check with a feeler gauge, the gap between the two plates is less than 0.1mm. Then, the Q235 steel material with a thickness of 1.5mm is cut off on the end face to be welded by milling, and the stainless steel layer is retained; at this time, the titanium layer is a step of 1.5mm protruding from the base layer. Then use the milling method to open the groove of the base layer, the angle is 30° on one side, and the thickness of the blunt edge is 2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com