Onboard fuel separation for octane-on-demand using membrane distillation

A technology of fuel separation and membrane distillation, applied in the direction of semi-permeable membrane separation, liquid fuel feeder, membrane, etc., can solve the problem of ineffective use of gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

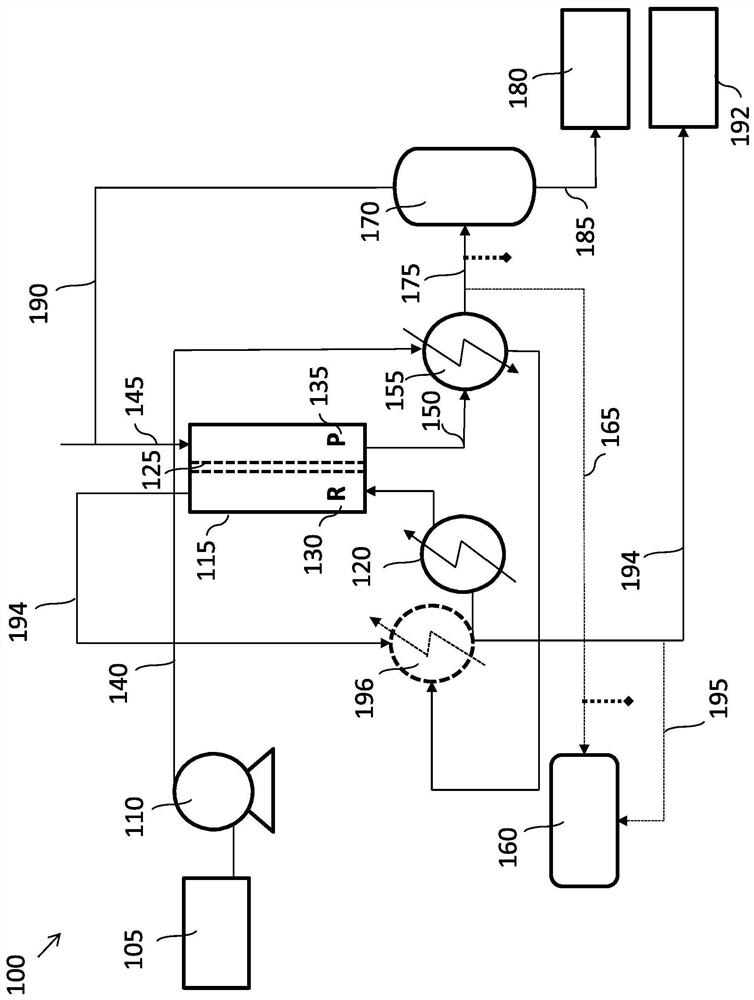

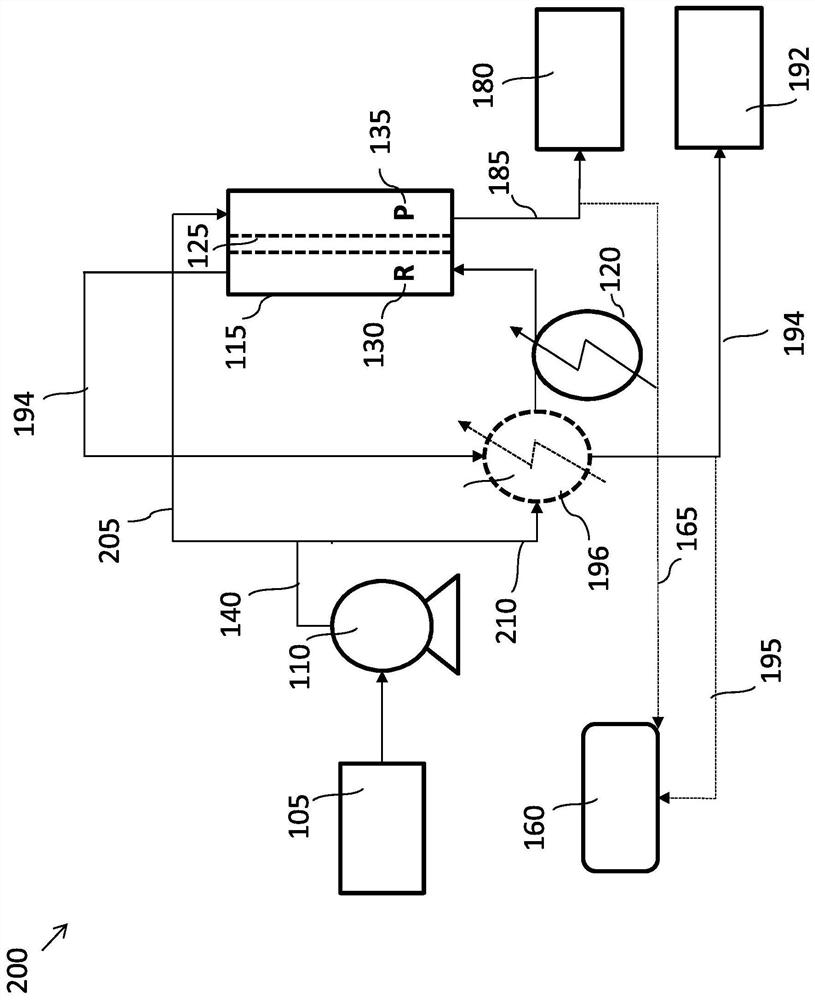

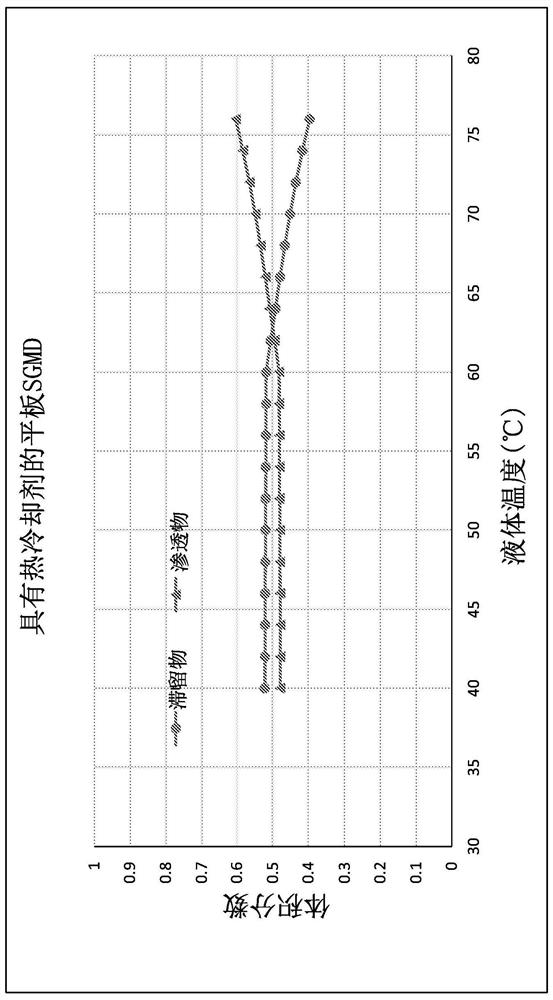

[0024] The present application describes onboard systems and methods for separating fuel. In particular, the present application describes systems and methods for on-board fuel separation using membrane distillation. The present application addresses challenges related to gasoline fuel efficiency and carbon emissions of internal combustion engines, among others, and provides solutions to such technical challenges.

[0025] In one or more embodiments, the onboard system includes a source fuel tank for containing liquid fuel, such as gasoline, and a pump for delivering the liquid fuel from the source fuel tank to the membrane module. A membrane module may include membranes, retentate channels, and permeate channels. The membrane module is configured to separate the liquid fuel into a high octane fraction and a low octane fraction, wherein the high octane fraction collects in the retentate channel and the low octane fraction diffuses through the membrane to the permeate channel....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com