Multi-wheeled arm space robot facing large rolling target

A space robot and target technology, which is applied in the field of multi-wheel arm space robot and spacecraft space grasping end effector, can solve the problem of high fuel consumption, and achieve the effects of reducing energy consumption, stable capture, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

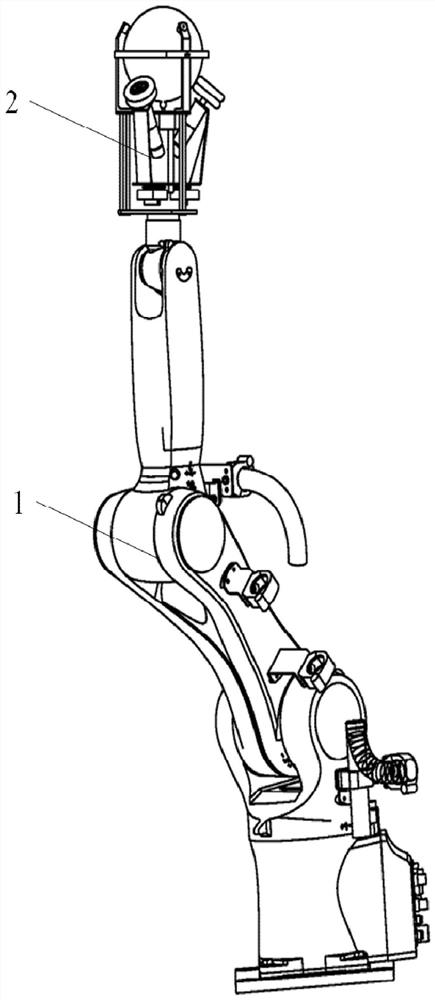

[0030] Such as figure 1 , 2 , a space robot with multi-wheeled arms facing a large rolling target, including a mechanical arm and an end effector of the mechanical arm; the end effector of the mechanical arm includes a mechanical arm 1 and an end effector 2; the end effector 2 is mounted on a end of arm 1;

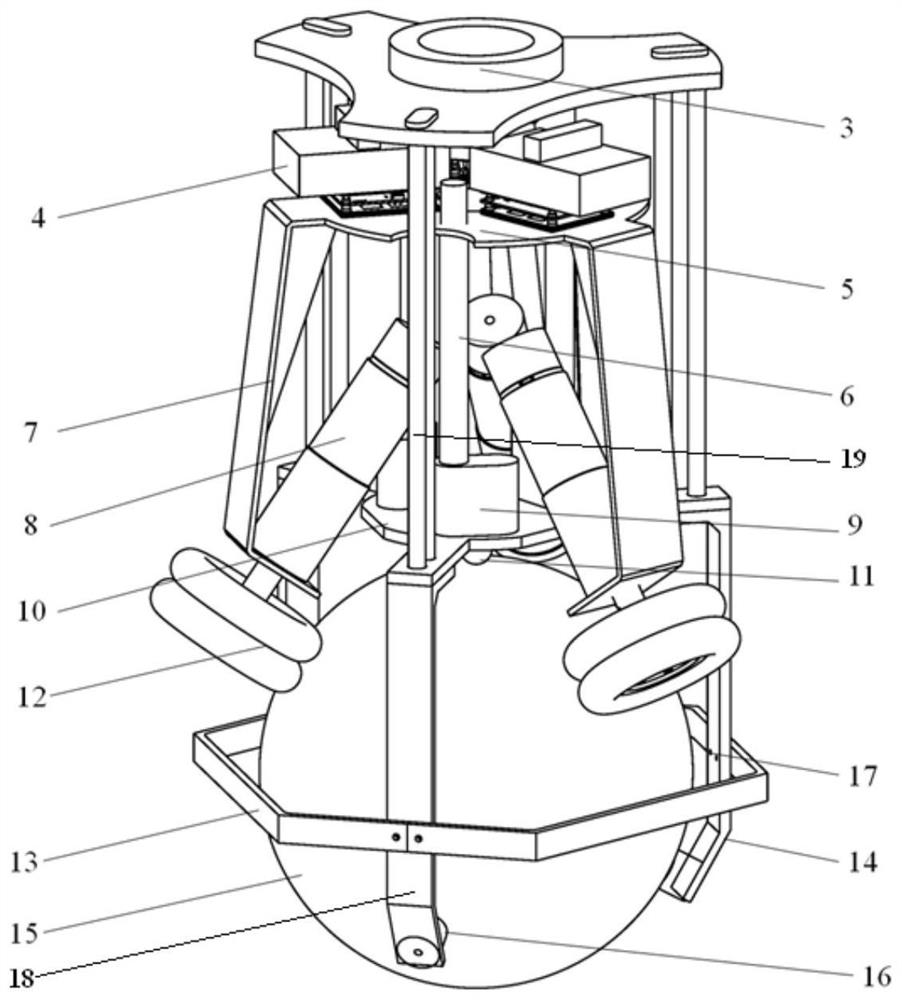

[0031] The end effector 2 includes an end effector mounting flange 3, a servo motor driver 4, a movable suspension 5, a linear module clutch system 6, a motor flange bracket 7, a servo motor 8, a linear module clutch driver 9, a fixed Suspension 10, limit ball bearing 11, Omni wheel 12, drive ball 15, omnidirectional bearing 16, laser measurement sensor 17 and drive ball support 18; One end of described motor flange support 7 is provided with movable suspension 5, so The movable suspension 5 is provided with a servo motor driver 4, and the other end of the motor flange bracket 7 is provided with a servo motor 8 and an omni wheel 12, and the servo motor 8 is used to contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com