A kind of pure bromobutyl rubber inner liner and its mixing method and application

A technology of bromobutyl rubber and airtight layer, which is applied in the field of rubber mixing, can solve problems such as carbon black agglomeration, achieve good airtightness, avoid abnormal damage, and be easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

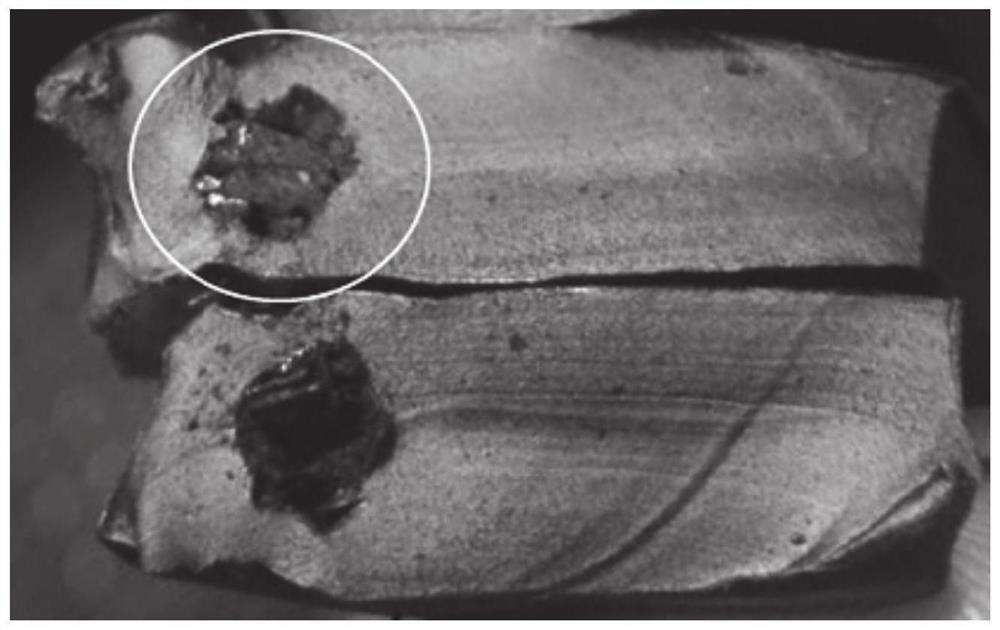

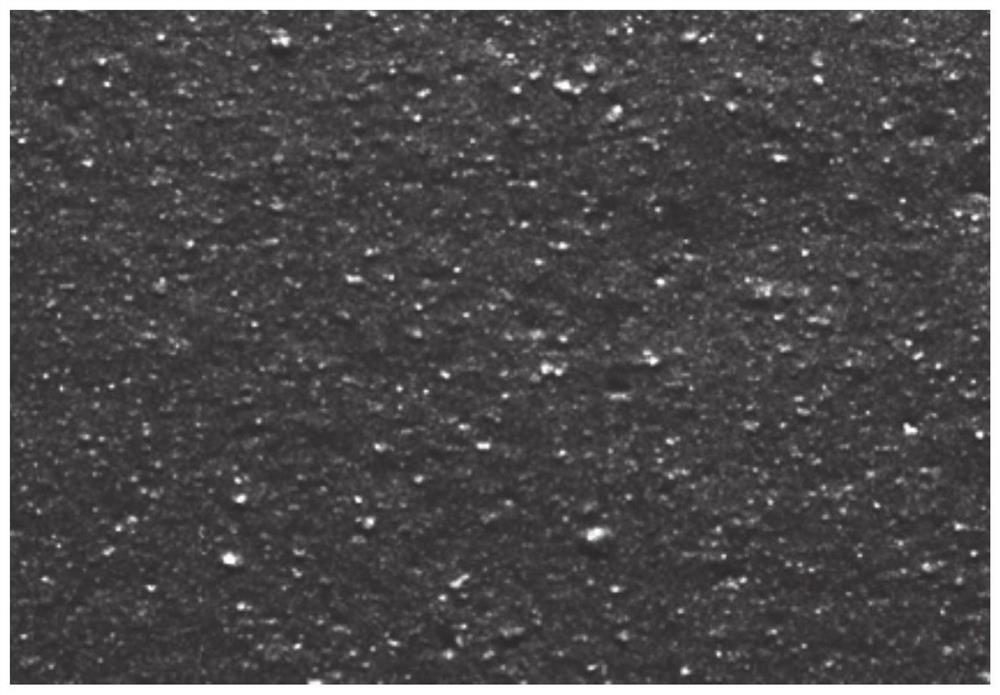

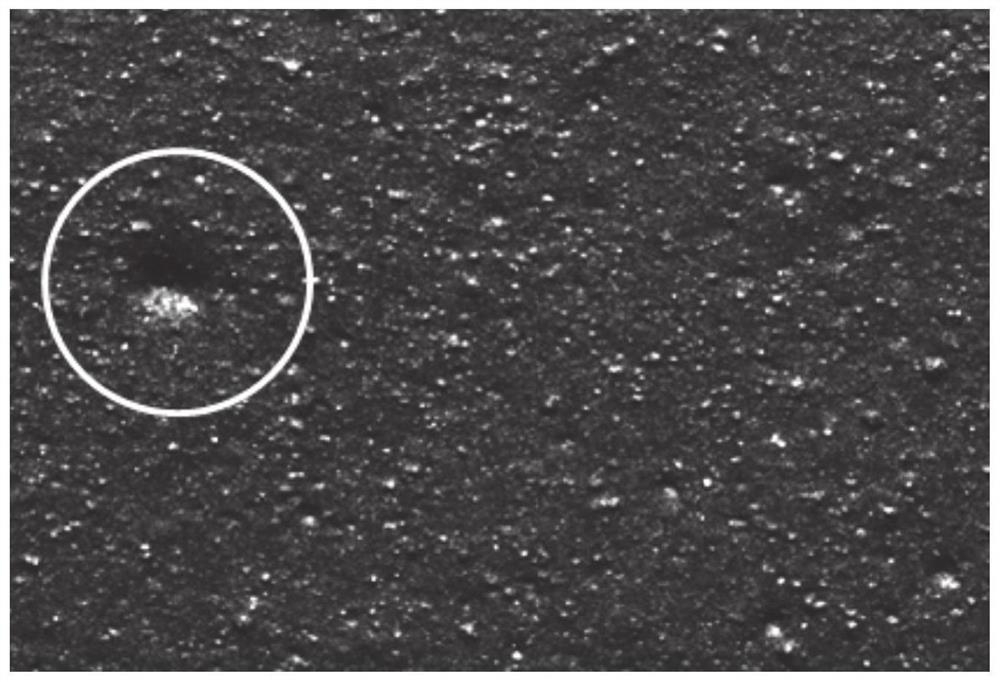

Image

Examples

Embodiment 1

[0050] HF Group GK420 Internal Mixer is used for the first stage of masterbatch, the rotor is a shear type full square rotor, and the upper bolt pressure is 50N / cm 2 , mixing room, rotor temperature 40 ℃, put bromobutyl rubber, homogenizer 40MSF, stearic acid, magnesium oxide into the internal mixer at the same time, put all the carbon black, speed 27 rpm, press the top bolt To 90°C, lift the top bolt, add environmental protection oil, rotate at 37 rpm, press the top bolt to 130°C, lift the top bolt, rotate at 20 rpm, press the top bolt to 138°C to remove glue, use a screw The extruder is unloaded, and after cooling, it is parked for 6-8 hours for final rubber mixing. The final rubber mixing adopts HF Group GK255 type internal mixer, the rotor is ZZ2 rotor, and the pressure of the top bolt is 45N / cm 2 , the temperature of the mixing room and the rotor is 40°C, put the masterbatch, zinc oxide, MBTS, and sulfur into the internal mixer at a speed of 20 rpm, press the top bolt fo...

Embodiment 2

[0052] HF Group GK420 Internal Mixer is used for the first stage of masterbatch, the rotor is a shear type full square rotor, and the upper bolt pressure is 50N / cm 2 , mixing room, rotor temperature 40 ℃, put bromobutyl rubber, homogenizer 40MSF, stearic acid, magnesium oxide into the internal mixer at the same time, put all the carbon black, rotate at 30 rpm, press the top bolt To 95°C, lift the top bolt, add environmental protection oil, rotate at 33 rpm, press the top bolt to 125°C, lift the top bolt, rotate at 25 rpm, press the top bolt to 138°C to remove glue, use a screw The extruder is unloaded, and after cooling, it is parked for 6-8 hours for final rubber mixing. The final rubber mixing adopts HF Group GK255 type internal mixer, the rotor is ZZ2 rotor, and the pressure of the top bolt is 45N / cm 2 , the temperature of the mixing room and the rotor is 40°C, put the masterbatch, zinc oxide, MBTS, and sulfur into the internal mixer at a speed of 20 rpm, press the top bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com