Efficient winding and placing device for industrial cloth

A technology for placing devices and industrial fabrics, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., which can solve the problems of large weight and volume of fabrics, inconvenient fabrics, and poor lamination, so as to speed up work efficiency , to ensure the effect of the degree of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

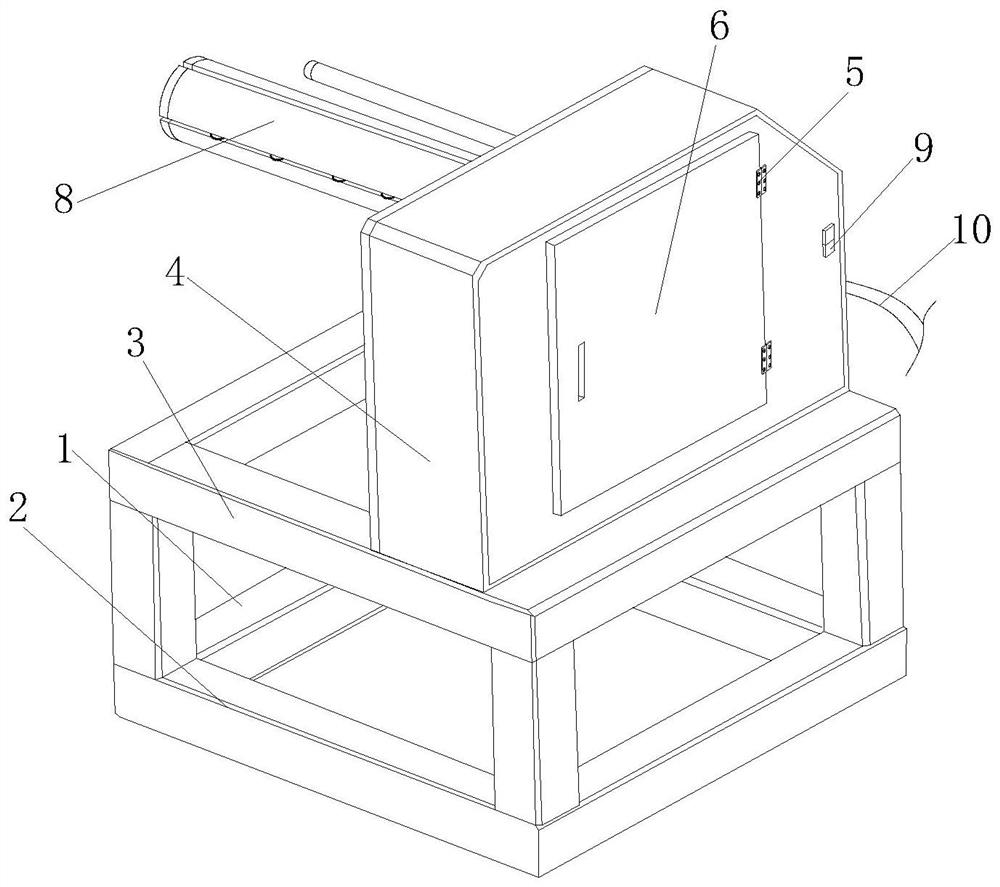

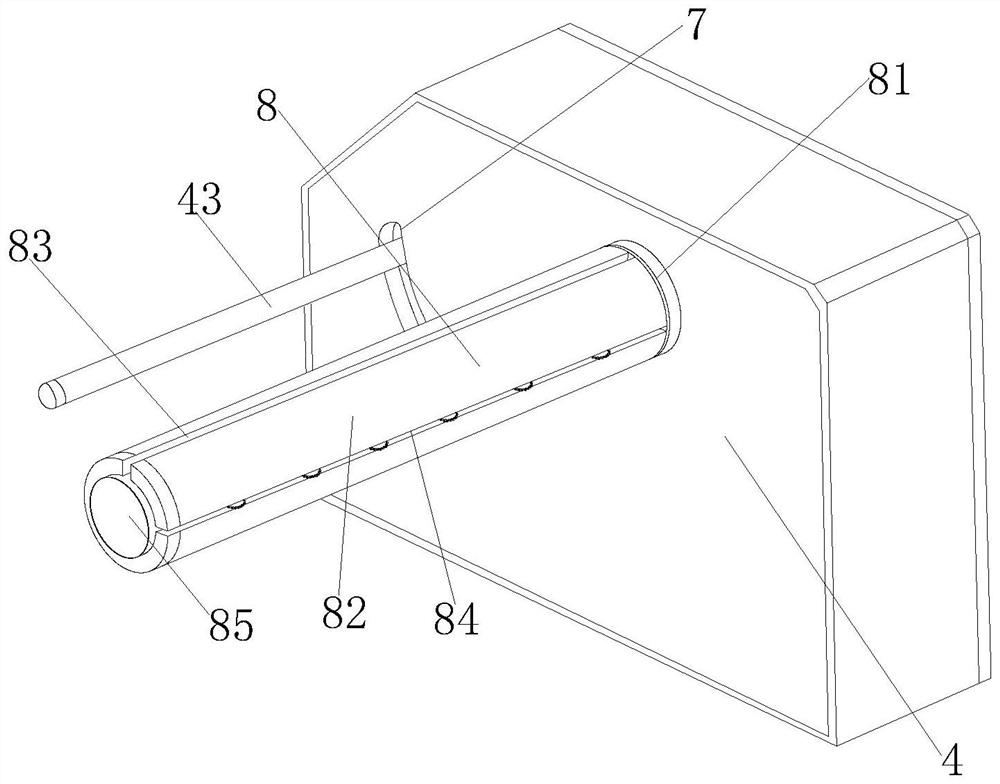

[0030] see figure 1 and figure 2 , a high-efficiency rolling and placing device for industrial cloth of the present invention, the rolling main body 1 includes a bottom frame 2, a top frame 3, a power bin 4, a hinge 5, a cover plate 6, a chute 7, a roller assembly 8, The control switch 9 and the power cord 10 are integrally formed on the top of the bottom frame 2 with a top frame 3, and the top right side of the top frame 3 is fixedly connected with a power compartment 4 by bolts, and the rear part of the right side of the power compartment 4 is connected to the cover plate 6 through a hinge 5. Hinged, a chute 7 is provided on the rear side of the left part of the power bin 4, and the roller assembly 8 is inserted into the inside of the power bin 4 to connect with it. A control switch 9 is arranged on the rear right side of the power bin 4, and a The power cord 10 and the roller assembly 8 include a connection plate 81, a cylinder holder 82, an upper slot 83, a rectangular g...

Embodiment 2

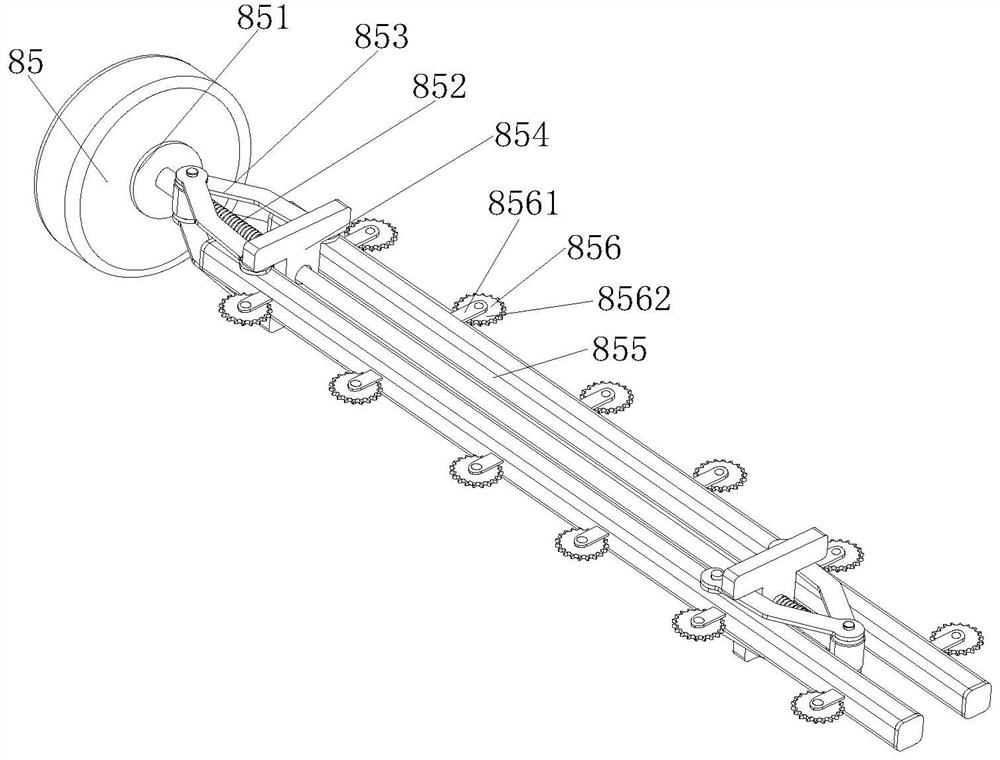

[0035] In the high-efficiency rolling and placing device for industrial cloth of the present invention, the two ends of the threaded rod 852 have threaded structures, and the threaded places on both sides of the threaded rod 852 are respectively inserted into the inner sides of two V-shaped frames 853 to be threaded with them, which is beneficial to drive The V-shaped frame is folded and unfolded, and there are two V-shaped frames 853 and clamping blocks 854, and the two V-shaped frames 853 and the clamping blocks 854 are distributed symmetrically front and back on the support bar 855, which is convenient to drive the support bar 855 to expand and support There are twelve wheels 856 in total, and six are equidistantly arranged on both sides of the support bar 855. At the same time, the support wheels 856 run through the inner side of the rectangular groove 84. Under the contact between the cloth and the support wheels 856, through the support wheels 856 Rotation facilitates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com