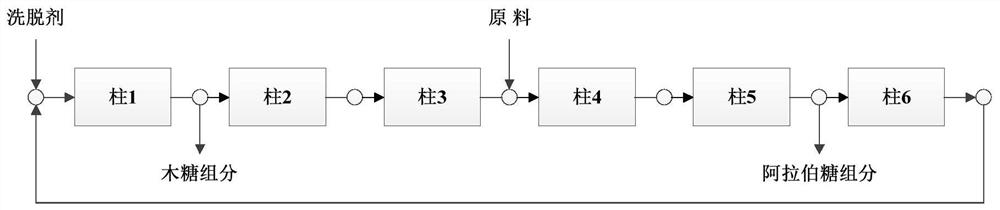

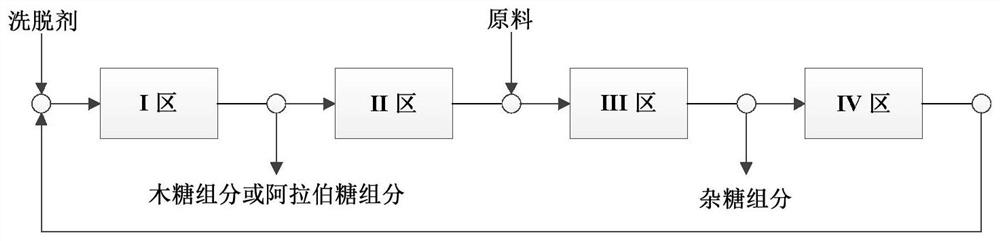

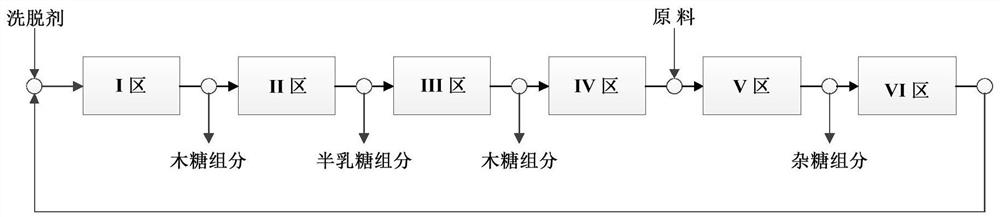

A method for simultaneously producing xylose, arabinose and galactose by using batch simulated moving bed chromatography

A technology for simulating moving bed and arabinose, applied in chemical instruments and methods, monosaccharides, sugar derivatives, etc., can solve the problem of reducing the yield of xylose and arabinose crystallization products, ineffective recovery of galactose, and reducing resource utilization efficiency and other issues, to achieve the effect of improving the utilization rate of biomass resources, reducing the amount of resin and the number of chromatographic columns, and reducing investment and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for simultaneously producing xylose, arabinose and galactose by using batch simulated moving bed chromatography is as follows.

[0055](1) Pretreatment of xylose mother liquor: the total sugar refraction of xylose mother liquor is about 60%, of which, by mass fraction, xylose content is 45% to 52%, arabinose content is 20% to 23%, and glucose content is 12% to 13.5% %, the content of galactose is 7% to 10%, and the content of cellobiose and mannose is 2% to 5%. Dilute the xylose mother liquor with deionized water. After dilution, the refractive concentration is about 25%. Inoculate the active dry yeast powder into the xylose mother liquor at a ratio of 0.3% (m / V), blow air to oxygenate and control the temperature at 25-35°C, and ferment After 24 hours, the glucose content in the liquid after fermentation is lower than 1%, and the miscellaneous sugar content is lower than 0.5%.

[0056] After fermentation, the liquid is finely filtered to remove colloid, protei...

Embodiment 2

[0062] A method for simultaneously producing xylose, arabinose and galactose by using batch simulated moving bed chromatography is as follows.

[0063] (1) Pretreatment of xylose mother liquor: the total sugar refraction of xylose mother liquor is about 60%, of which, by mass fraction, xylose content is 45% to 52%, arabinose content is 20% to 23%, and glucose content is 12% to 13.5% %, the content of galactose is 7% to 10%, and the content of cellobiose and mannose is 2% to 5%. Dilute the xylose mother liquor with deionized water. After dilution, the refractive concentration is about 22%. Inoculate the active dry yeast powder into the xylose mother liquor at a ratio of 0.5% (m / V), blow air to oxygenate and control the temperature at 30-35°C, and ferment After 15 hours, the glucose content in the fermented liquid is lower than 2%, and the cellobiose and mannose contents are lower than 0.5%.

[0064] After fermentation, the liquid is finely filtered to remove colloid, protein, ...

Embodiment 3

[0070] A method for simultaneously producing xylose, arabinose and galactose by using batch simulated moving bed chromatography is as follows.

[0071] (1) Pretreatment of xylose mother liquor: the total sugar refraction of xylose mother liquor is about 60%, of which, by mass fraction, xylose content is 45% to 52%, arabinose content is 20% to 23%, and glucose content is 12% to 13.5% %, the content of galactose is 7% to 10%, and the content of cellobiose and mannose is 2% to 5%. Dilute the xylose mother liquor with deionized water. After dilution, the refractive concentration is about 25%. Inoculate the active dry yeast powder into the xylose mother liquor at a ratio of 1% (m / V), blow air to oxygenate and control the temperature at 30-35°C, and ferment After 12 hours, the glucose content in the fermented liquid is lower than 1.5%, and the cellobiose and mannose contents are lower than 0.5%.

[0072] After fermentation, the liquid is finely filtered to remove colloid, protein, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com