Composition containing polyglycolic acid and application of composition

A technology of polyglycolic acid and composition, which is applied in the direction of drilling composition, chemical instruments and methods, etc., and can solve problems such as failure, weakened plugging strength, and inability to soften the bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

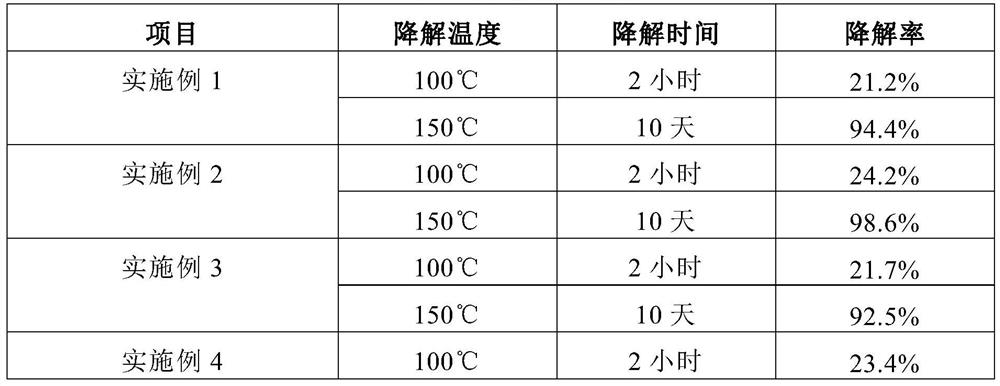

Embodiment 1

[0110] The composition containing polyglycolic acid in this embodiment comprises i) polyglycolic acid and ii) a functional thickener mixed with polyglycolic acid and a degradation regulator, wherein the amount of polyglycolic acid is 100 parts by weight, and the functional thickener The consumption of is 12 parts by weight, and the consumption of degradation modifier is 3 parts by weight.

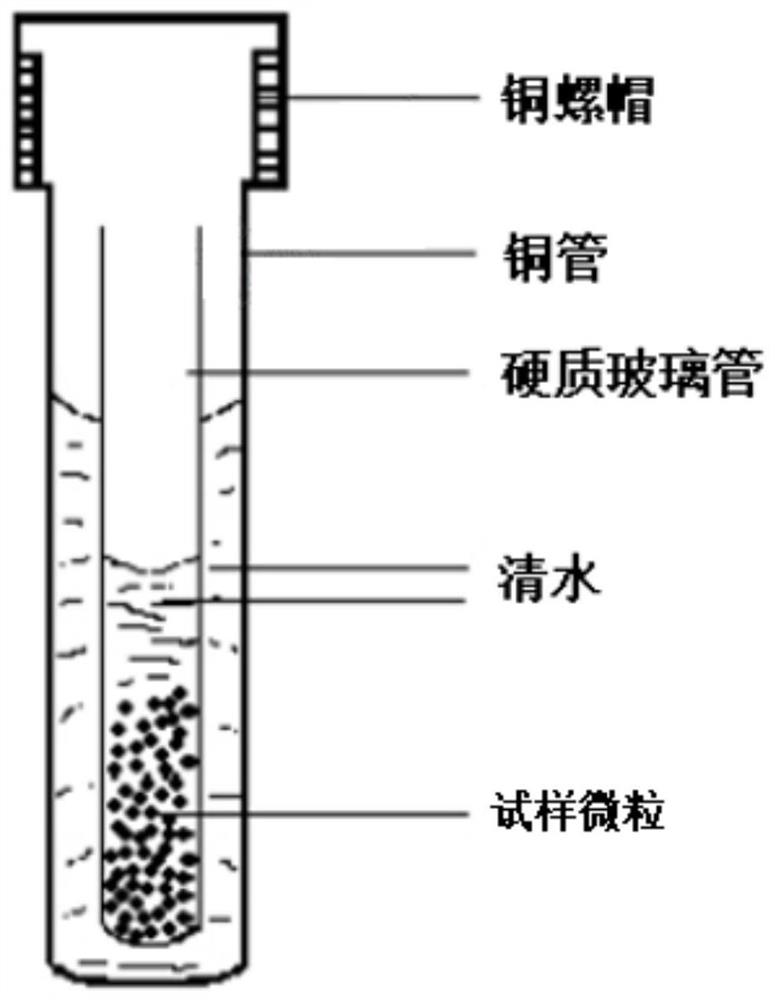

[0111] The polyglycolic acid used in this embodiment is a homopolymer of glycolic acid, and its shape is granular, and its degradation test can adopt the following steps:

[0112] Step I): Weigh 2 parts of mass and both are M 0 Polyglycolic acid, and placed in a constant temperature drying oven, dried at 60 ° C for 48 hours;

[0113] Step II): Put the dried 2 parts of polyglycolic acid into hard glass tubes with one end open respectively, and then add appropriate amount of water to completely soak the polyglycolic acid, and then put the hard glass tubes into the hard glass tubes with clean...

Embodiment 2

[0135] The composition containing polyglycolic acid in this embodiment comprises i) polyglycolic acid and ii) a functional thickener mixed with polyglycolic acid and a degradation regulator, wherein the amount of polyglycolic acid is 100 parts by weight, and the functional thickener The consumption of is 18 parts by weight, and the consumption of degradation regulator is 2 parts by weight.

[0136] The polyglycolic acid used in this embodiment is a glycolic acid-lactic acid copolymer, wherein the mass content of glycolic acid repeating units is about 56%.

[0137] The polyglycolic acid used in this example is fibrous, and the degradability of polyglycolic acid can be measured by the same method as that used in Example 1 for testing the degradability of polyglycolic acid.

[0138] It was measured that the degradation rate of the polyglycolic acid used in this example was less than 20% in 100°C water within 2 hours, and greater than 90% in 150°C water after 15 days.

[0139] Th...

Embodiment 3

[0147] The composition containing polyglycolic acid in this embodiment comprises i) polyglycolic acid and ii) a functional thickener mixed with polyglycolic acid and a degradation regulator, wherein the amount of polyglycolic acid is 100 parts by weight, and the functional thickener The consumption of is 20 parts by weight, and the consumption of degradation modifier is 6 parts by weight.

[0148] The polyglycolic acid used in this example is a homopolymer of glycolic acid, which is in the form of flakes. The degradability of polyglycolic acid can be measured by the same method as that used in Example 1 for testing the degradability of polyglycolic acid.

[0149] It was measured that the degradation rate of the polyglycolic acid used in this example was less than 20% in 100°C water within 2 hours, and greater than 90% in 150°C water after 15 days.

[0150] The functional thickener used in this example contains the following components in mass percent: 59.85% xanthan gum, 35% p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com