Fabricated steel structure beam-column energy dissipation connector

A technology for connecting keys and steel structures, applied to building components, building structures, protective buildings/shelters, etc., can solve problems such as inability to dissipate energy and difficult repairs, reduce repair and reinforcement costs, and improve overall Anti-seismic performance, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

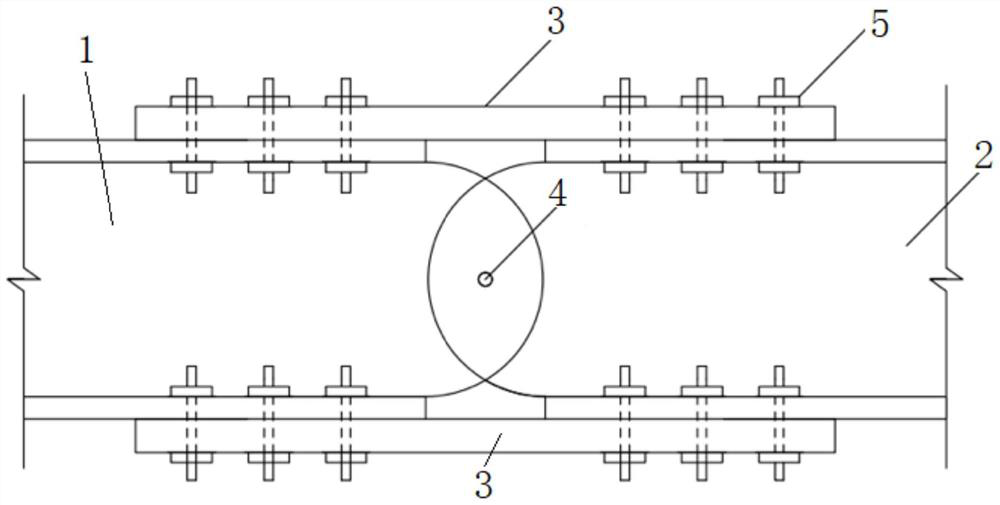

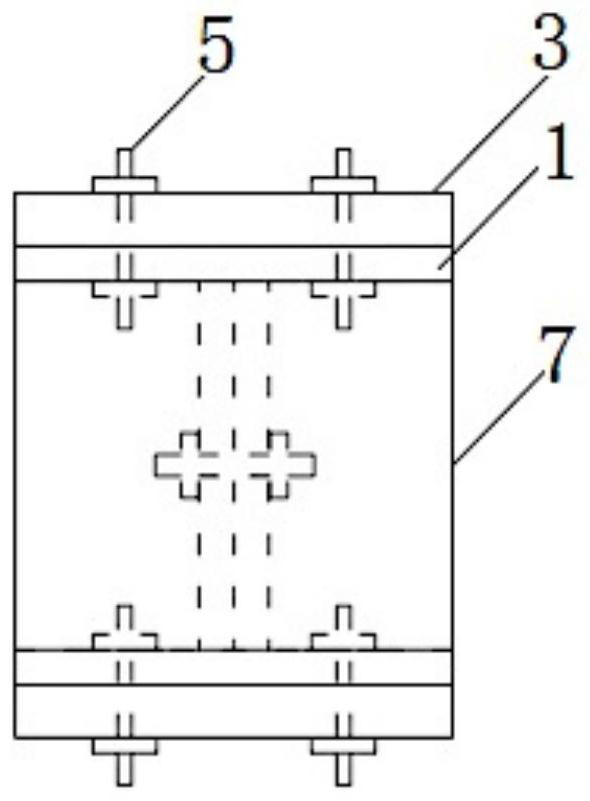

[0045] This embodiment provides an assembled steel structure beam-column energy-dissipating connection key, including two connecting steel beams on the left and right, and the two connecting steel beams on the left and right are hinged and fixed by hinge bolts; wherein, the connecting steel beam near the column on the left side is shorter , the distance between the right connecting steel beam and the column is approximately equal. Cut the 200-400mm of the hinged ends of the left and right connecting steel beams respectively, cut off the upper and lower flanges of the left and right connecting steel beams, and cut the web into an arc-shaped structure; Hinge bolt holes are provided at the corresponding positions of the web ends of the two connecting steel beams to ensure that the left and right connecting steel beams are aligned up and down when the two connecting steel beams are connected by hinge bolts through the hinge bolt holes.

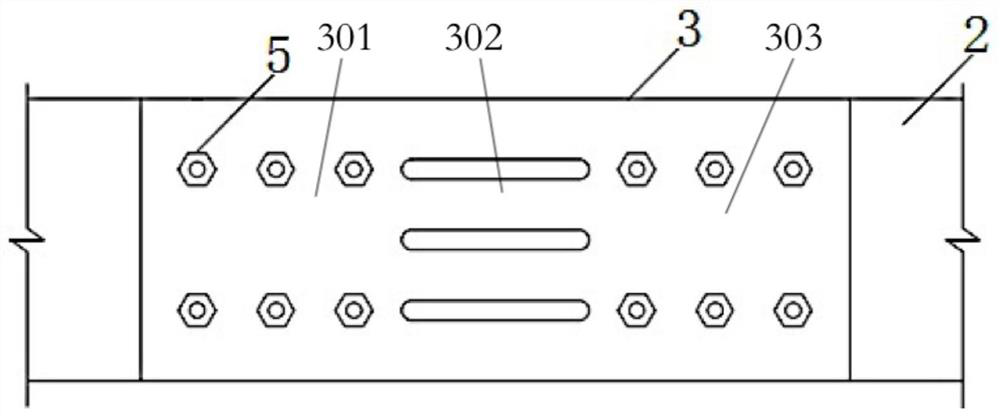

[0046] In this embodiment, energy-dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com