Forming method and quality detection method of concrete aggregate detection model

A technology for concrete aggregates and detection models, which is applied to measurement devices, neural learning methods, biological neural network models, etc., can solve the problems of being affected by ambient light, low detection accuracy, unstable results, etc. High detection accuracy, satisfying the effect of real-time processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

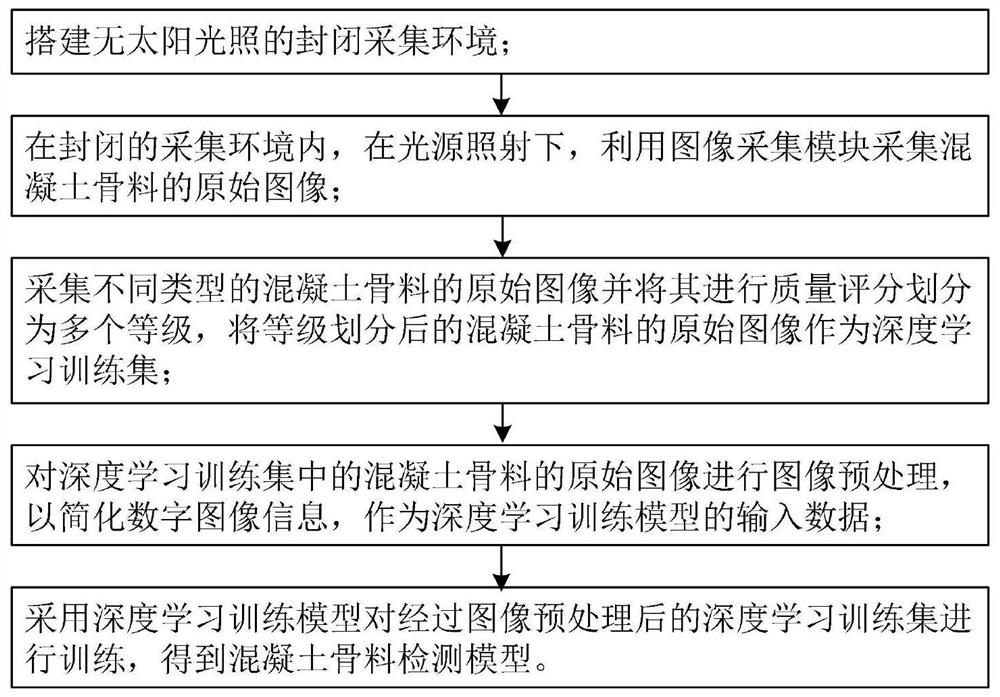

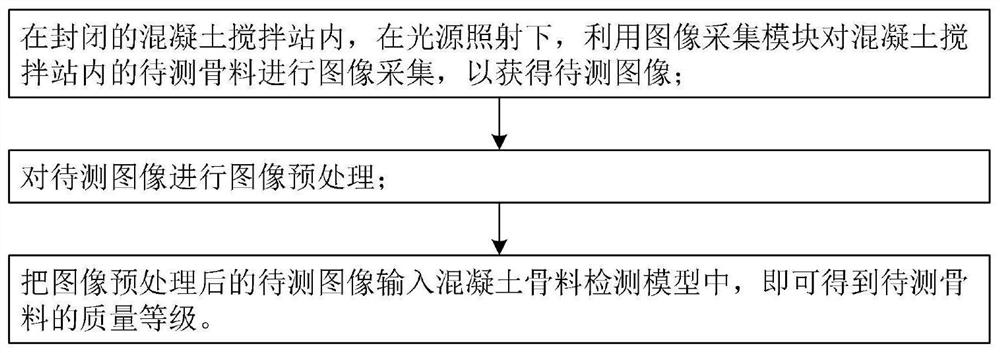

[0040] see figure 1 As shown, this embodiment discloses a method for forming a concrete aggregate detection model, including the following steps:

[0041] Build a closed collection environment without sunlight; the reason for setting up a closed collection environment is the need to simulate the environmental parameters of the mixing plant in a closed setting.

[0042] In a closed acquisition environment, under the light source, the original image of the concrete aggregate is collected by the image acquisition module;

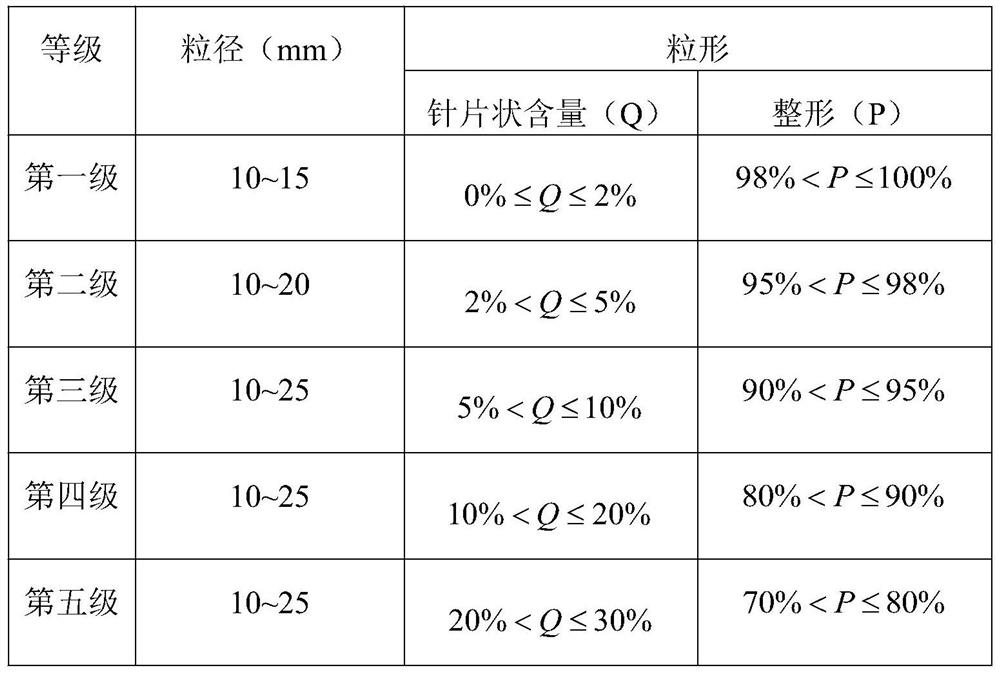

[0043] Collect the original images of different types of concrete aggregates and divide them into multiple grades for quality scoring, and use the graded original images of concrete aggregates as a deep learning training set;

[0044] Perform image preprocessing on the original image of concrete aggregate in the deep learni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com