Polaroid image measuring instrument and detection method

A technology for image measuring instruments and polarizers, applied in measuring devices, instruments, optics, etc., can solve the problems of repeated taking and placing of polarizers, inconvenience for operators to detect, etc., to improve detection efficiency, wide application range, and ensure docking accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

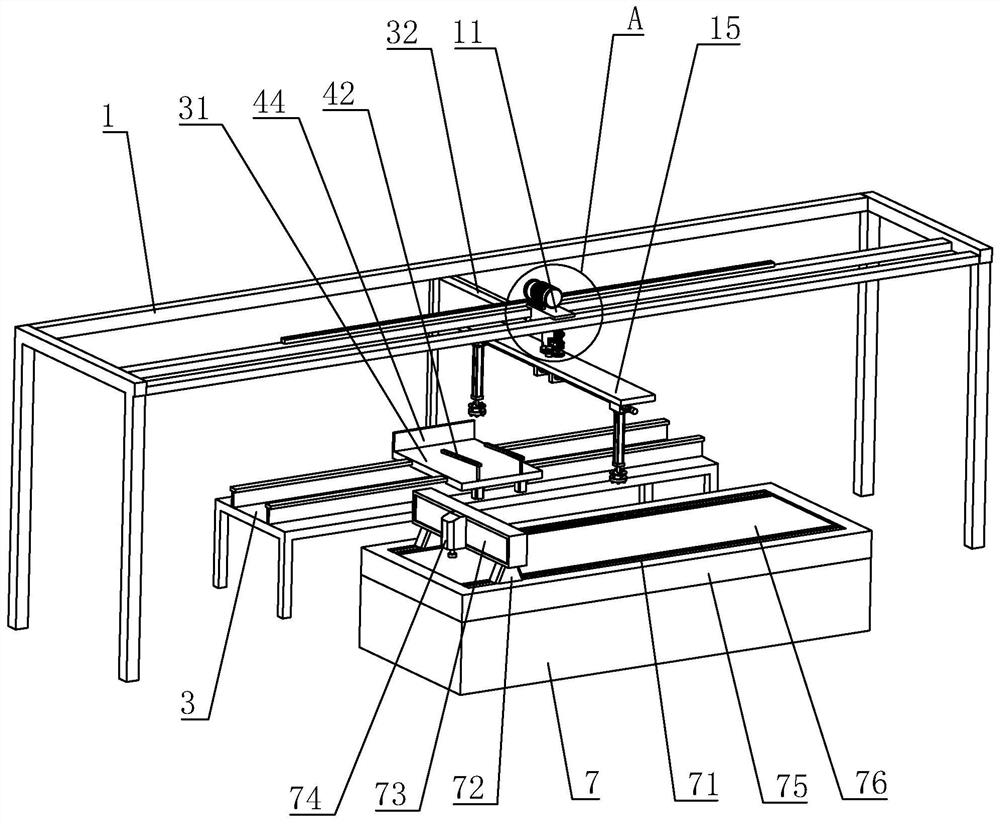

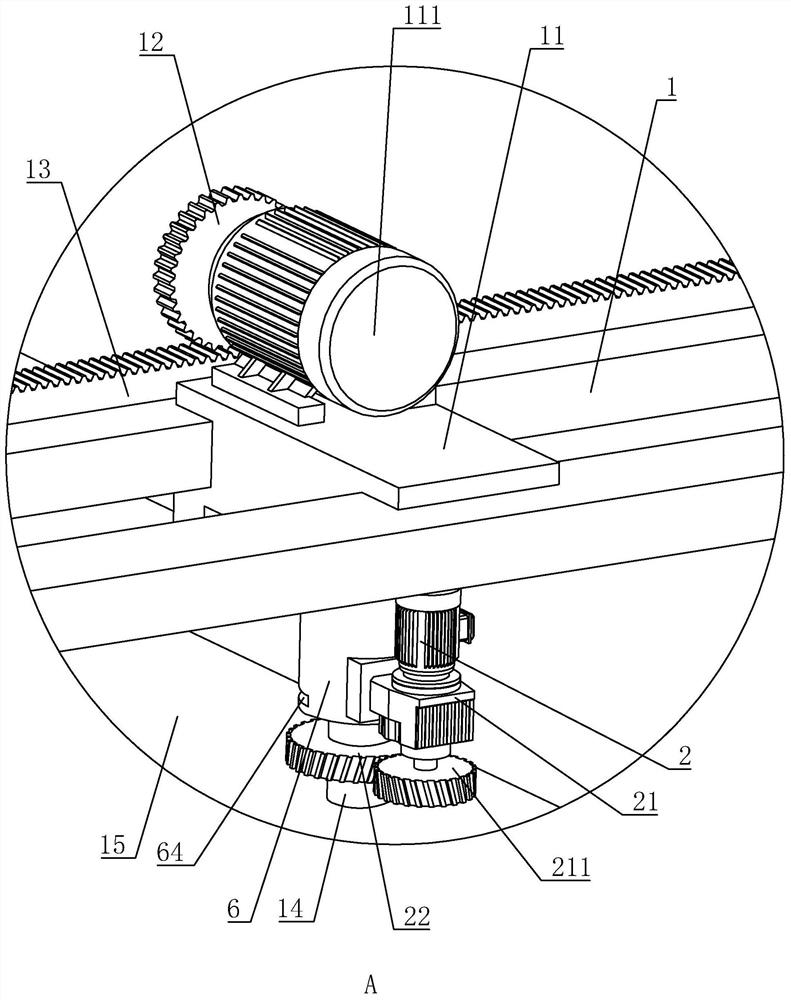

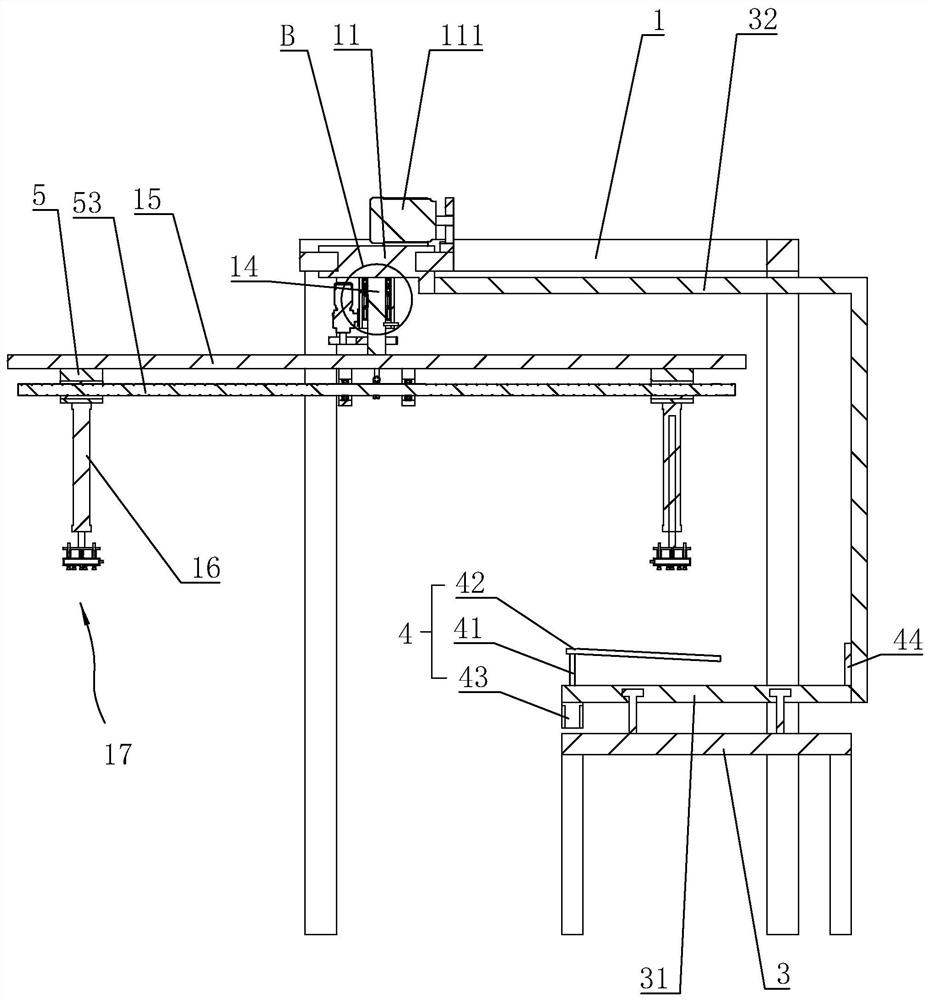

[0041] Embodiment one: if figure 1 As shown, it is a polarizer image measuring instrument disclosed in the present invention, which includes a machine 7, a frame 1 and a storage platform 3. One end of the machine 7 is connected with an X-axis track 71, and the X-axis track 71 slides with the gantry column 72. Connection, the gantry column 72 is fixedly connected with the gantry of the machine platform 7, a digital camera 74 is arranged on the horizontal sliding of the gantry of the machine platform 7, a marble platform 75 is arranged on the machine platform 7, and a glass platform 76 is fixedly connected on the marble platform 75, and the glass platform 76 is fixedly connected to the gantry. Platform 76 tops are facing digital camera 74, and the tail of machine platform 7 is connected with organic platform 7 electric control cabinets, is used to control the X-axis direction movement of machine platform 7 gantry, and the bottom of machine platform 7 is provided with machine plat...

Embodiment 2

[0053] Embodiment 2: A polarizer detection method, including a polarizer image measuring instrument, A1, first turn on the power of the measuring instrument, and then turn on the power of the computer to prevent downtime, and clear the glass platform 76 during the waiting process to avoid dust Wipe the measuring platform with a cloth.

[0054] A2. Execute the InSpec software, and the measuring instrument performs self-test.

[0055] A3. Place the polarizer to be tested on the flat plate 31 in advance, and the two vacuum chucks 17 advance synchronously with the platform. During the movement, the vacuum chucks 17 hold the polarizer in turn and place them on the glass platform 76 at intervals.

[0056] A4. The inspector controls the movement of the gantry column 72 and the digital camera 74 through the control panel, so that the digital camera 74 moves directly above the polarizer to focus, acquire an image and present it on the display screen.

[0057] A5. Call out the coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com