Quasi-solid electrolyte for flexible electrochromic film and preparation method of quasi-solid electrolyte

A quasi-solid-state, chromic technology, applied in the field of materials, can solve the problems such as the preparation method of flexible electrochromic thin film needs to be studied, the color changing voltage is high, and the color changing range of the color changing thin film device is narrow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

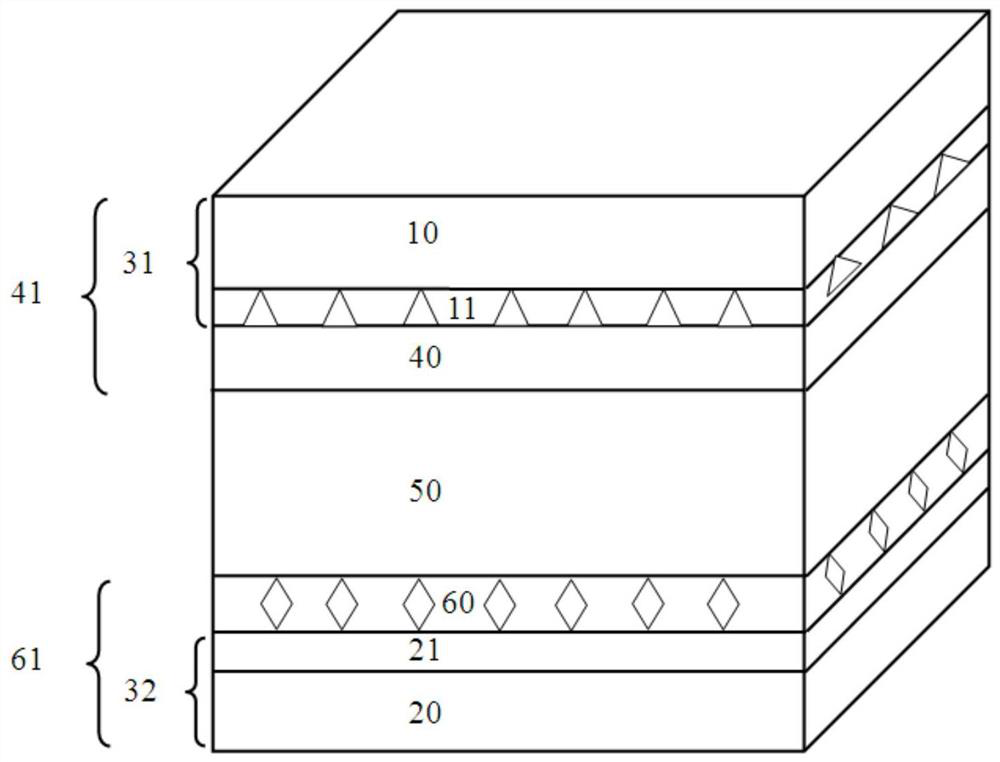

Method used

Image

Examples

Embodiment 1

[0061] 1. Raw materials

[0062] Quasi-solid electrolyte includes: PVB resin, dispersant, inorganic lithium salt, nano-inorganic particles and additives;

[0063] The molecular weight of PVB resin is 70,000, and the dosage is 32.5% by weight in the quasi-solid electrolyte;

[0064] The inorganic lithium salt is lithium bis(pentafluoroethylsulfonyl)imide, and the dosage is 26.4% by weight in the quasi-solid electrolyte;

[0065] The dispersant is tetraethylene glycol dimethyl ether, and the consumption is 38.4% by weight in the quasi-solid electrolyte;

[0066] The nano-inorganic particles are hydrophobic silicon dioxide with a particle size of 7nm, calculated by weight and mass percentage in the quasi-solid electrolyte, 2.0%;

[0067] The auxiliary agent includes cyclohexylcarbodiimide, which is used in quasi-solid electrolyte by weight and mass percentage, and the dosage is 0.5%, and the antioxidant is tert-butyl p-hydroxyanisole, which is used in quasi-solid electrolyte by...

Embodiment 2

[0082] 1. Raw materials

[0083] The initial quasi-solid electrolyte includes: PVB resin, dispersant, inorganic lithium salt, nano-inorganic particles and additives;

[0084] The molecular weight of the PVB resin is 190,000, and the dosage is 37.4% by weight in the quasi-solid electrolyte;

[0085] The inorganic lithium salt is a mixture of lithium bis(pentafluoroethylsulfonyl)imide and lithium bis(fluorosulfonyl)imide with a mass ratio of 2:1, and the dosage is 13.1% by weight in the quasi-solid electrolyte;

[0086] The dispersant is ethylene glycol dimethyl ether, and the consumption is 48% by weight in the quasi-solid electrolyte;

[0087] The nano-inorganic particles are hydrophobic titanium dioxide with a particle size of 20nm, and the dosage is 0.5% by weight in the quasi-solid electrolyte;

[0088] The auxiliary agent includes a water-removing agent of hexamethyldisilazane, which is used in an amount of 0.8% by weight in the quasi-solid electrolyte; the defoamer is p...

Embodiment 3

[0096] 1. Raw materials

[0097] Quasi-solid electrolyte includes: PVB resin, dispersant, inorganic lithium salt, nano-inorganic particles and additives;

[0098] The molecular weight of the PVB resin is 120,000, and the dosage is 24% by weight in the quasi-solid electrolyte;

[0099] The inorganic lithium salt is lithium bis(trifluoromethanesulfonyl)imide, and the dosage is 37.2% by weight in the quasi-solid electrolyte;

[0100] The dispersant is tetraethylene glycol dimethyl ether, and the consumption is 36.2% by weight in the quasi-solid electrolyte;

[0101]The nano-inorganic particles are hydrophobic nano-silicon dioxide, with a particle size of 14nm, calculated by weight and mass percentage in the initial quasi-solid electrolyte, 1.4%;

[0102] Auxiliary agents include 1, (3-dimethylaminopropyl)-3-ethylcarbodiimide as a water-removing agent, in the initial quasi-solid-state electrolyte by weight and mass percentage, the amount is 1%, and the antioxidant is Dibutyl hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com