A method for predicting the remaining life of mechanical equipment based on real-time data monitoring

A technology for mechanical equipment and life prediction, applied in complex mathematical operations, etc., can solve problems such as difficult to achieve real-time prediction, and achieve the effects of efficient prediction methods, saving manpower, and accurate probability results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

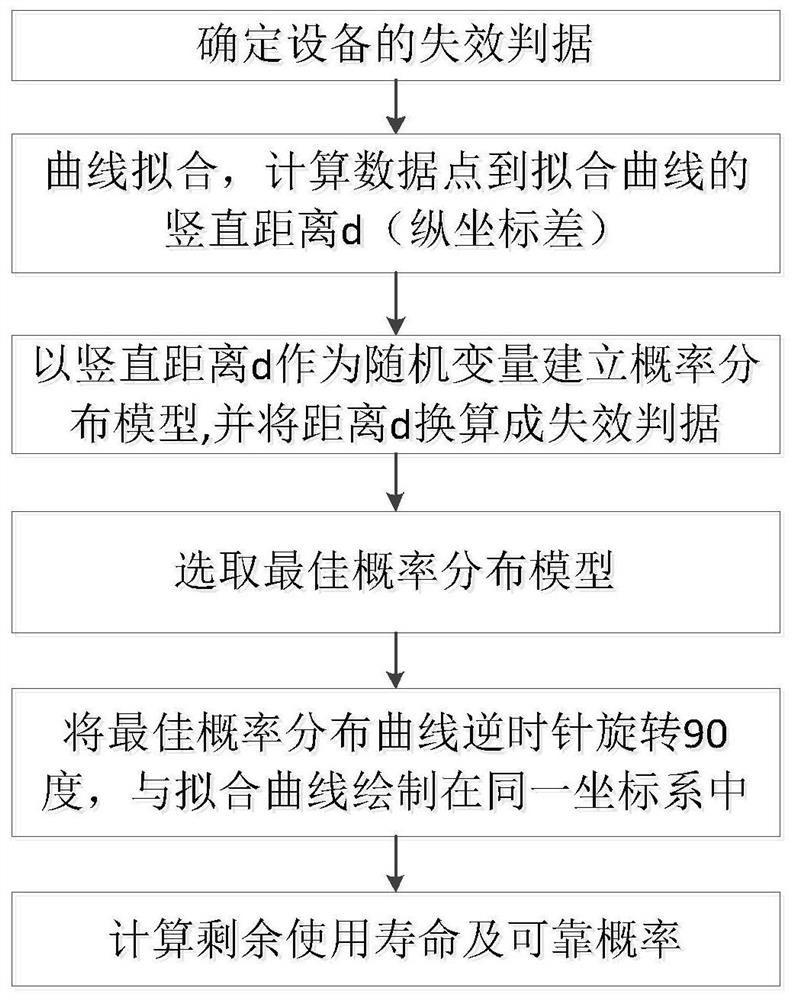

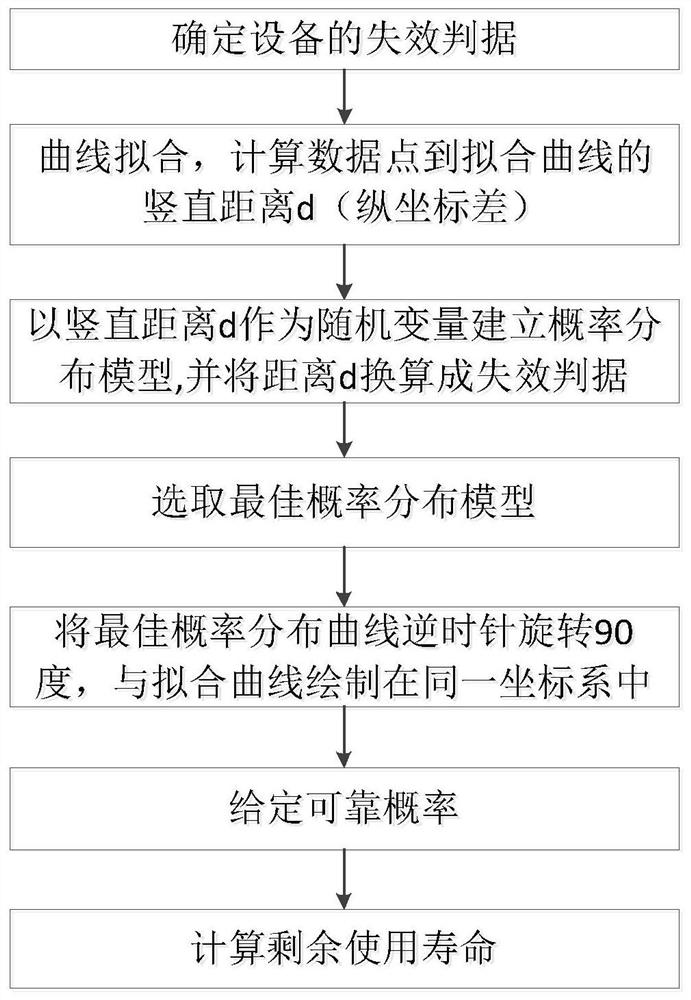

Method used

Image

Examples

Embodiment 1

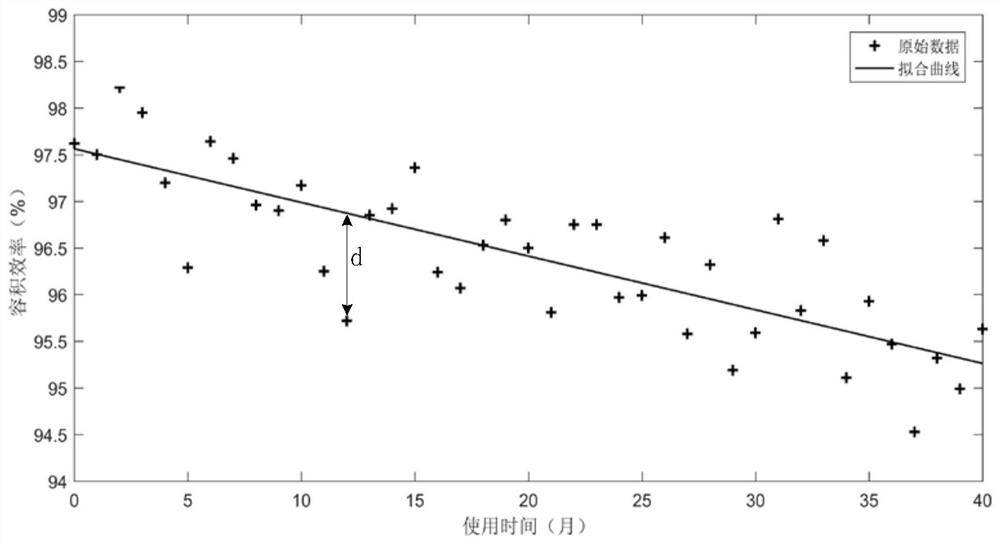

[0099] The plunger pump is an important device of the hydraulic system and belongs to a kind of hydraulic pump. It relies on the reciprocating movement of the plunger in the cylinder to change the volume of the sealed working chamber to realize oil suction and pressure. In order to predict and judge the remaining life of the plunger pump in normal operation, the specific implementation steps are as follows:

[0100]S1. According to the performance parameters of the plunger pump, determine the failure criterion of the plunger pump with volumetric efficiency η, and define its failure by reducing the volumetric efficiency by 4%. The volume of mixed gas actually inhaled by the cylinder is divided by the cylinder volume. The ratio of the actual flow rate of the pump or motor to the theoretical flow rate of the pump or motor, the calculation expression of the volumetric efficiency of the axial piston pump is as follows:

[0101]

[0102] Among them, η v - volumetric efficiency ...

Embodiment 2

[0122] The plunger pump is an important device of the hydraulic system and belongs to a kind of hydraulic pump. It relies on the reciprocating movement of the plunger in the cylinder to change the volume of the sealed working chamber to realize oil suction and pressure. In order to predict and judge the remaining life of the plunger pump in normal operation, the specific implementation steps are as follows:

[0123] S1. According to the performance parameters of the plunger pump, determine the failure criterion of the plunger pump with volumetric efficiency η, and define its failure by reducing the volumetric efficiency by 4%. The volume of mixed gas actually inhaled by the cylinder is divided by the cylinder volume. The ratio of the actual flow rate of the pump or motor to the theoretical flow rate of the pump or motor, the calculation expression of the volumetric efficiency of the axial piston pump is as follows:

[0124]

[0125] in:

[0126] n v - volumetric efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com