Vacuum device, vacuum control method and ion implantation equipment

A vacuum device and ion technology, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of complex operation of ion vacuum gauges and long recovery time of ion implantation equipment, so as to shorten the recovery time and improve the service life , to prevent the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

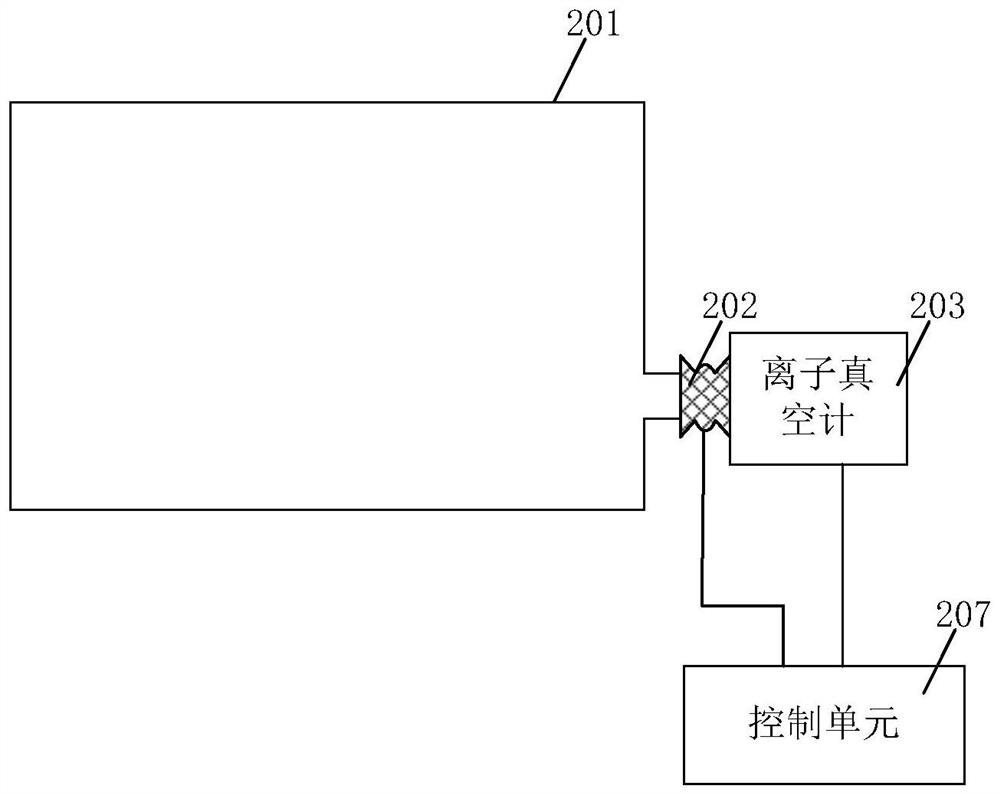

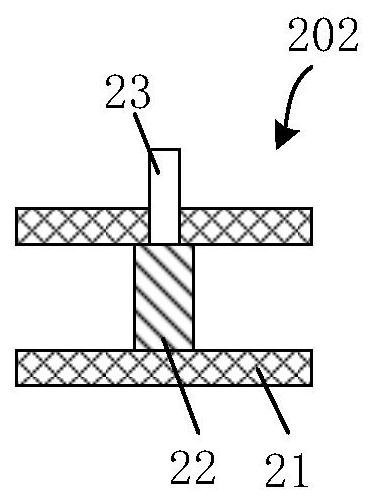

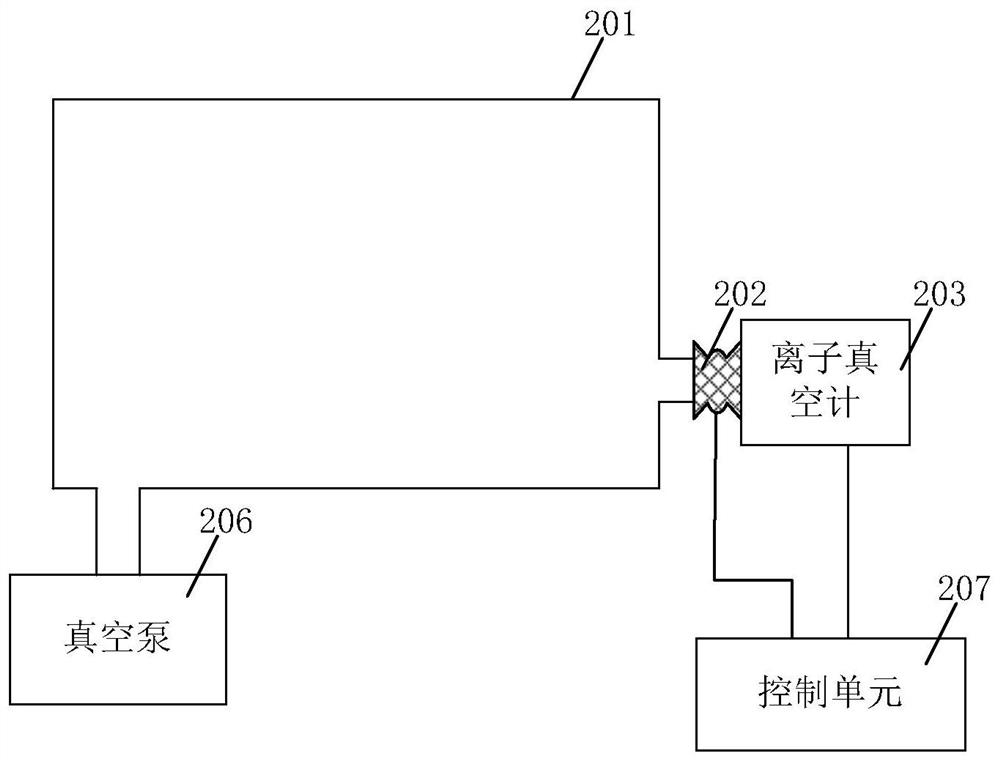

[0035] As stated in the background technology, it takes a long time to replace the ion vacuum timer and reset it.

[0036] The study found that the existing ion vacuum gauge is directly connected to the vacuum chamber, and the ion vacuum gauge must continuously monitor the vacuum condition in the vacuum chamber. In addition, the ion implantation equipment needs regular maintenance, and the vacuum chamber needs to be checked repeatedly during regular maintenance. The ion vacuum gauge will be repeatedly exposed to the atmosphere and foreign matter, which will affect the ion vacuum gauge and cause the ion vacuum gauge to be abnormal or damaged. When the ion vacuum gauge is abnormal or damaged, the ion implantation equipment will stop the injection immediately. Personnel just must shut down, close relevant vacuum pump one by one (vacuum pump is connected with vacuum chamber, to guarantee the vacuum degree in the vacuum chamber), and the vacuum chamber is exhausted so that the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com