Family shellfish cultivation device

A kind of shellfish and family technology, applied in fish farming, engine frame, supporting machine, etc., can solve the problems of inability to drain, the air is not ventilated, and die in the aquaculture device, so as to improve air circulation, improve the effect of seedlings, The effect of improving the cultivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

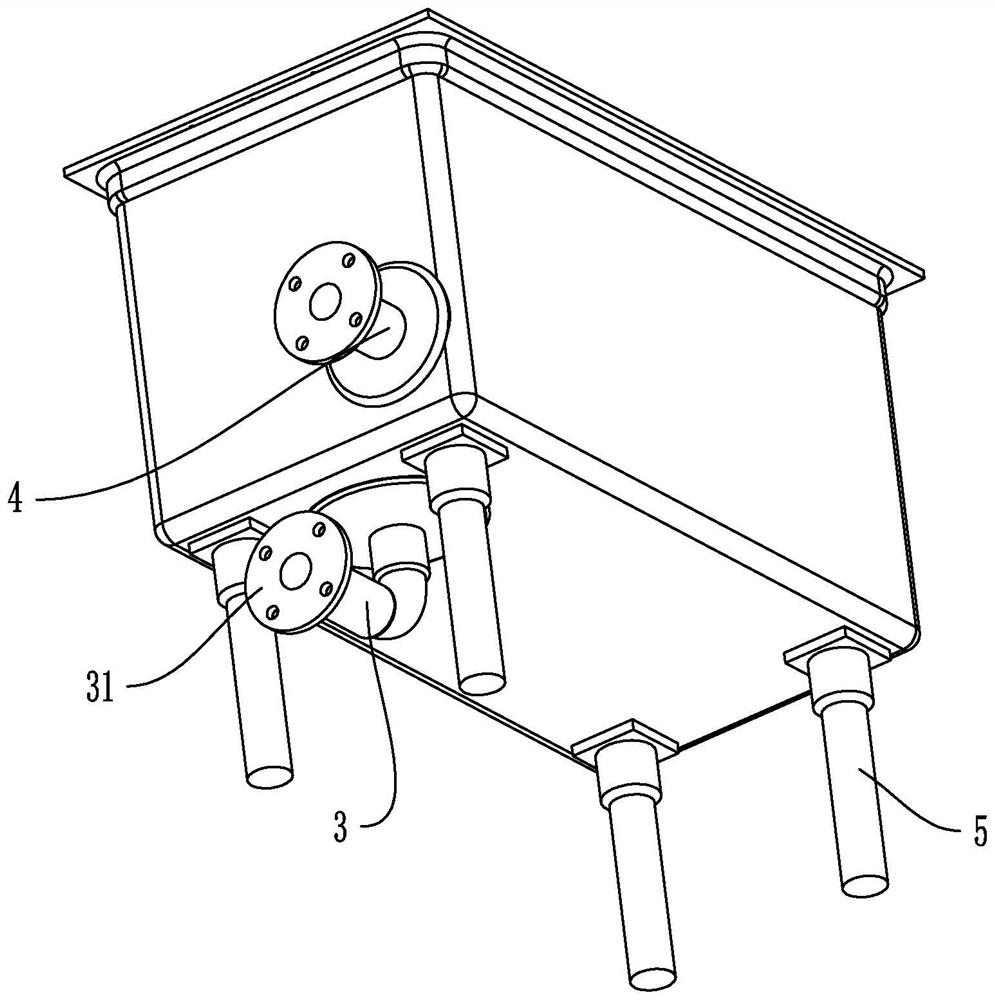

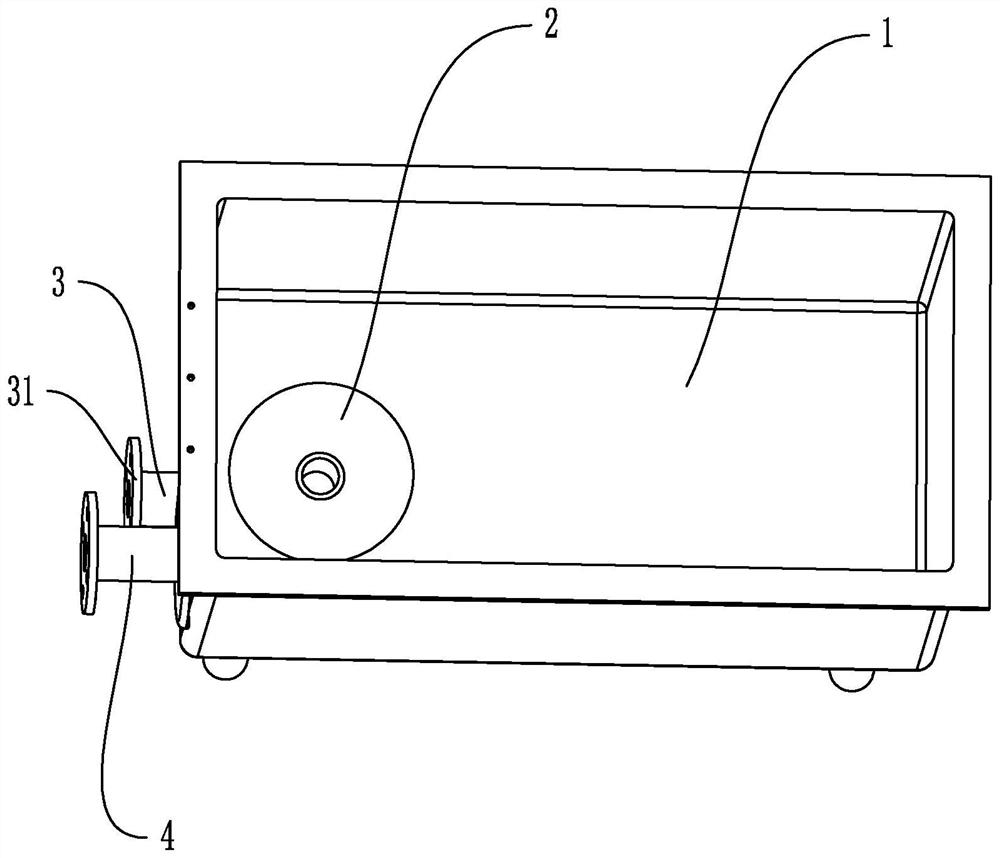

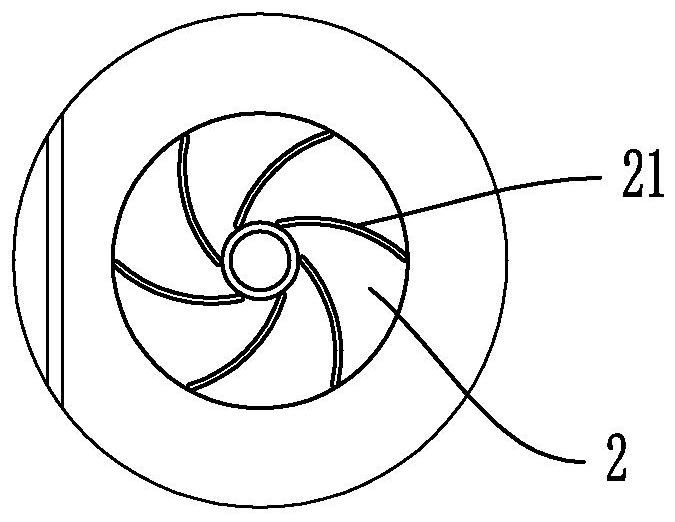

[0043] Embodiment 1, this embodiment discloses a kind of family shellfish culture device, such as Figures 1 to 3 As shown, it includes a body, and the body is provided with a culture cavity 1 with an upward opening. The bottom of the culture cavity 1 is provided with a connecting groove 2 that is compatible with it. The inside of the connecting groove 2 is provided with a spherical structure. The center of the groove 2 is fixed with a first connecting pipe 3 communicating with it. The first connecting pipe 3 is arranged in an L-shaped structure as a whole. One side of the body is also provided with a second connecting pipe 4 communicating with the breeding cavity 1. The inner diameters of the second connecting pipe 4 and the first connecting pipe 3 are equal in size, and the outlet ends of the second connecting pipe 4 and the first connecting pipe 3 are arranged parallel to each other and facing the same direction. The lower end of the body is also provided with a number of su...

Embodiment 2

[0047] Embodiment two, this embodiment is on the basis of embodiment one, such as Figures 4 to 7 As shown, the shading assembly 6 includes a shading baffle 61 and a shading bracket 62 slidably connected to the upper end of the body. The shading bracket 62 is provided with a shading sub-frame 63 matching it. 63 are fixedly connected with the above-mentioned light-shielding baffles 61, and the light-shielding baffles 61 are distributed at equal intervals, the lower side of the light-shielding sub-frame 63 is provided with a number of light-shielding support columns 631, and the light-shielding support columns 631 are interspersed with The shading sub-column 632 that moves up and down, the lower end of the shading sub-column 632 is fixedly connected with the shading bracket 62; the shading baffle 61 is used to block the strong light from the outside, so as to avoid the excessive light intensity affecting the effect of seedling cultivation, and the shading sub-frame 63 is supporte...

Embodiment 3

[0051] Embodiment three, this embodiment is on the basis of embodiment two, such as Figure 8 As shown, the support structure 5 includes a support base column 51 and a support sub-column 52 pierced on the support base column 51. The support base column 51 is provided with a lifting groove 511, and the lifting groove 511 is provided with a The matching lifting motor 53, the supporting sub-column 52 is fixedly connected with the lifting motor 53 by setting the lifting screw rod 54, the lower end of the supporting sub-column 52 is fixedly provided with a lifting nut 55 that is sleeved outside the lifting screw rod 54, and the supporting sub-column 52 Also be provided with the screw groove 521 that matches with lifting screw rod 54 inside; Support bottom column 51 and support sub-column 52 and lift motor 53 cooperate with each other, make the height of support structure 5 can be adjusted and then the height of body is adjusted, The lifting motor 53 drives the lifting screw mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com