Heat insulation protection device for vacuum preheating electron beam welding of pressure-resistant shell

A technology for electron beam welding and pressure-resistant shells, which is applied in the direction of electron beam welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of electron beam welding machine damage, heater winding, heat radiation, etc., to solve winding, improve Heating efficiency, effect of reducing radiant heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

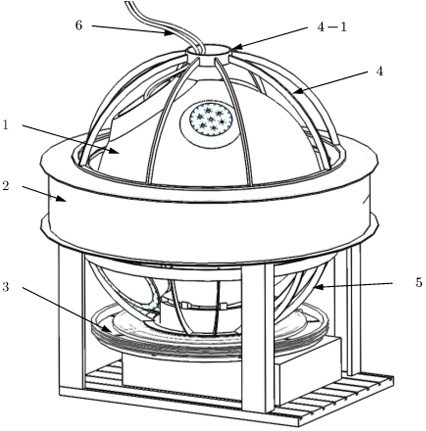

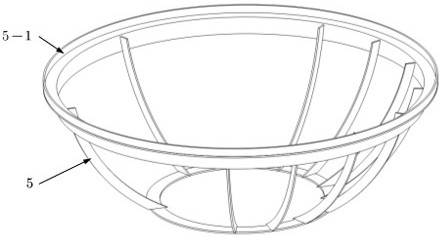

[0012] Such as Figure 1-2 As shown, a heat insulation protection device for vacuum preheating electron beam welding of pressure shells is used for heat insulation protection in vacuum preheating electron beam welding of pressure shells. The pressure shell 1 is spherical, The welding of the annular weld needs to be completed. The vacuum preheating electron beam welding device includes an electron beam welder, a turntable 3, a heating system 2 and a vacuum chamber. The pressure-resistant shell 1 is located above the turntable 3 and rotates with the turntable 3. , the heating system 2 is assembled with the pressure-resistant casing 1, and vacuum heating is performed in the vacuum chamber of the electron beam welding machine. The heating system 2 is composed of an inner heater and an outer heater, and the outer heater is supported on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com