Light anti-high-overload integrated bullet holder for electromagnetic rail gun

A technology for electromagnetic railguns and ammunition supports, which is applied to electromagnetic launchers, weapons without explosives, offensive equipment, etc., can solve the problems of high initial velocity of projectiles, reduce the launching efficiency and service life of electromagnetic railguns, and improve the storage speed performance. , the effect of reducing negative quality and processing difficulty, and increasing the life of the launch system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

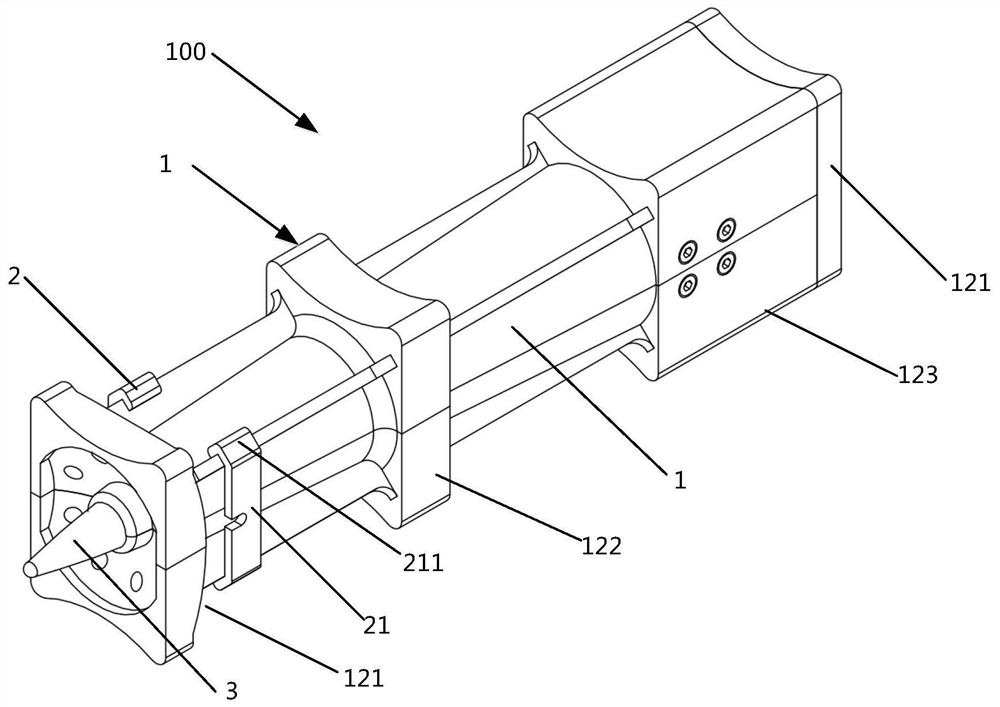

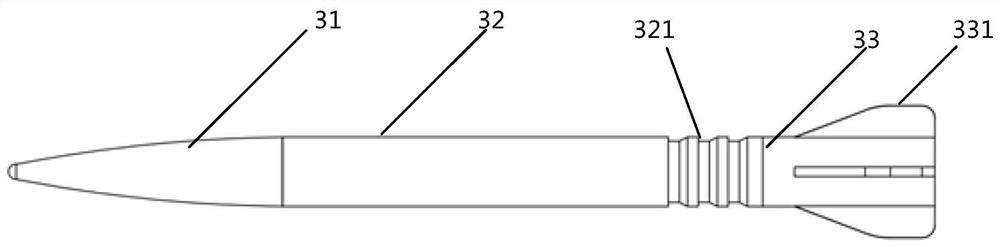

[0044] like figure 1 , 2 As shown, in one embodiment of the present invention, a lightweight anti-high overload integrated bullet holder 100 for an electromagnetic railgun is disclosed, which generally includes a bullet holder main body 1, a cassette belt 2, a flying body 3, and a protection holder 4 And the ring type bullet belt 5.

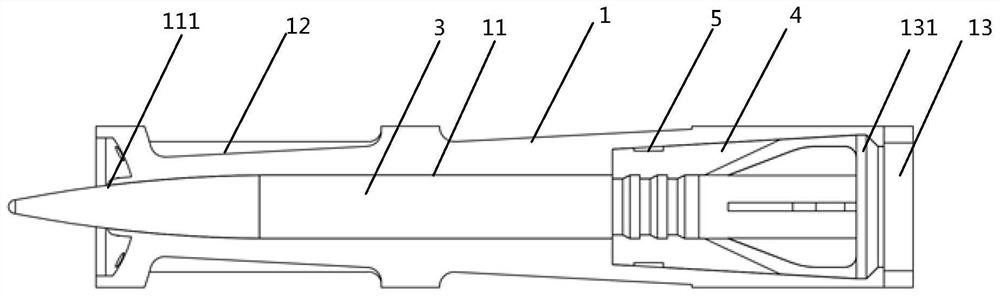

[0045] The bullet holder main body 1 is used as a container for accommodating the flying body 3, and the bullet holder main body 1 is divided into two symmetrical parts up and down in the axial direction, and includes a protective tube 12 with an accommodating cavity 11 inside, and one end of the protective tube 12 is provided with The outlet 111 communicating with the accommodation cavity 11 has a base 13 that closes the accommodation cavity 11 at the other end. The base 13 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com