Efficiency tester for rod-pumped well system

A system efficiency, pumping unit well technology, applied in the field of pumping unit well system efficiency tester, can solve problems such as large volume, loose interface, misjudgment of system efficiency diagnosis and analysis, etc., and achieve the effect of multiple on-chip resources and fast running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

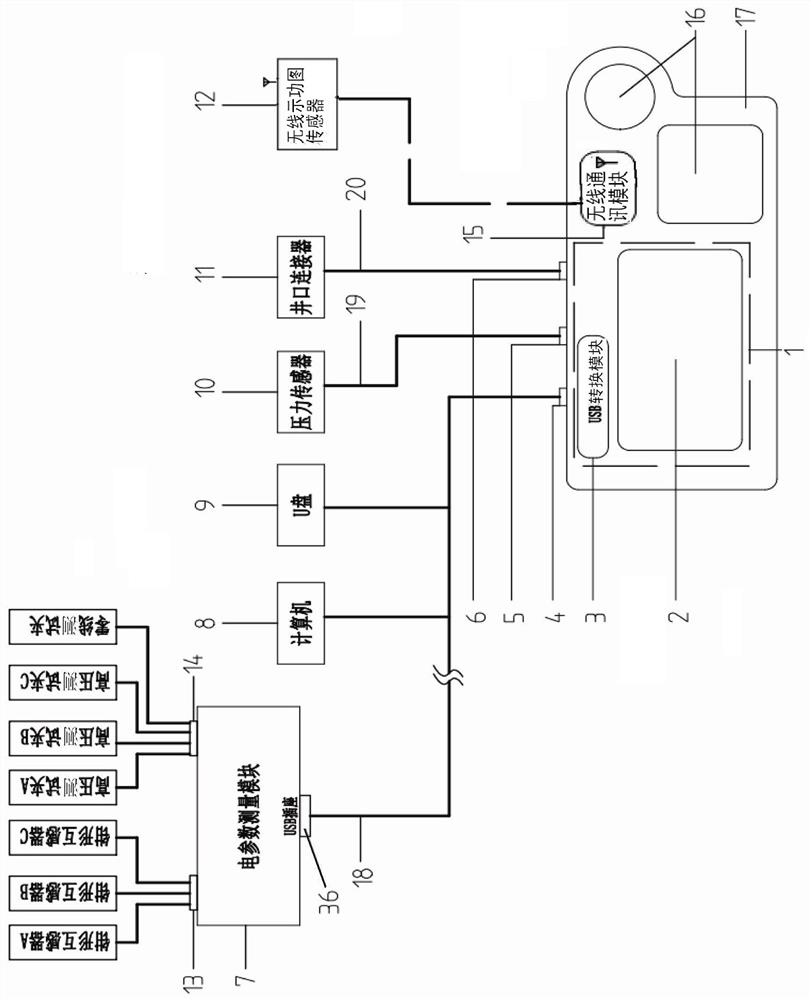

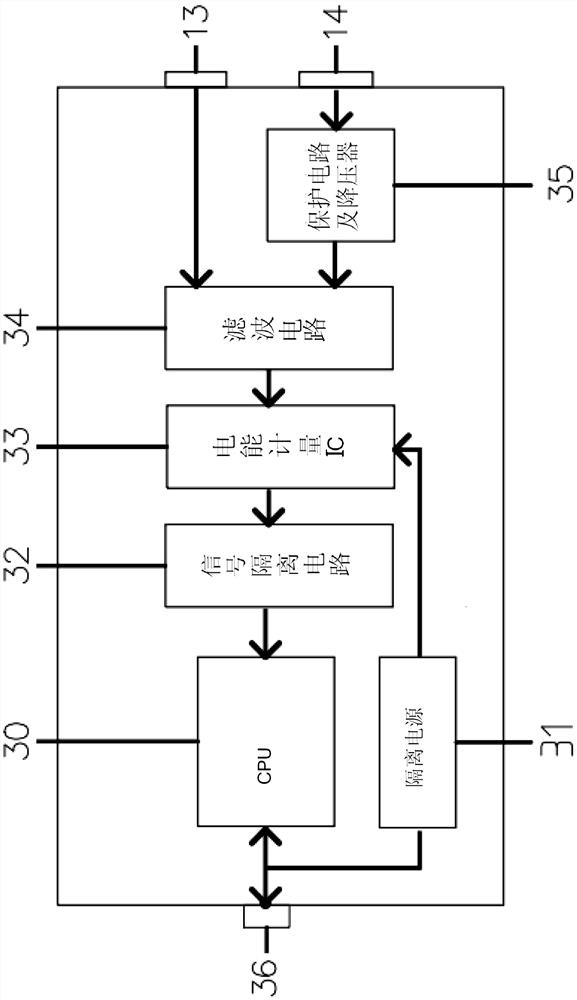

[0057] A pumping well system efficiency tester has a host 17 (hand operator).

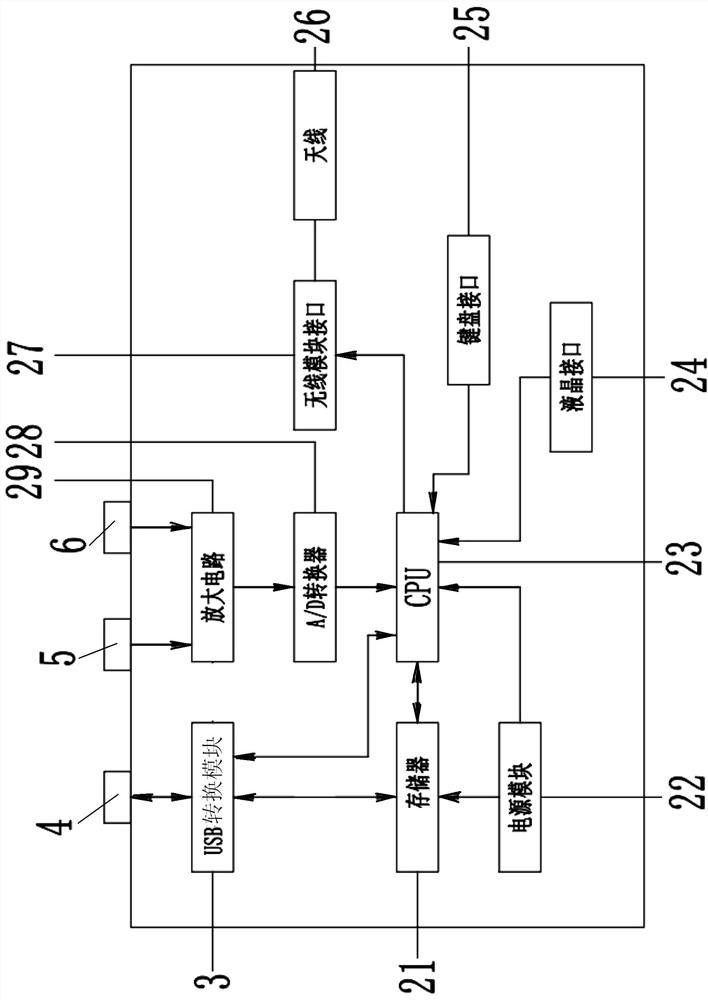

[0058] The host computer 17 has a host CPU processor 23 inside.

[0059] The pressure sensor 10 is connected to the host casing pressure test socket 5 through the host and the pressure sensor connection cable 19, and the host casing pressure test socket 5 is connected to the host amplifier circuit 29. (Pressure signal and moving liquid level signal amplifying circuit).

[0060] The wellhead connector 11 is connected to the main motor liquid level socket 6 through the host computer and the wellhead connector connecting cable 20 , and the main motor liquid level socket 6 is connected to the host amplifier circuit 29 .

[0061] The host amplifying circuit 29 is correspondingly connected with the host CPU processor 23 through the host A / D converter 28 .

[0062] The host CPU processor 23 is correspondingly connected to the host wireless communication module interface 27 (433MHZ), and the host wireles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com