Shii-take spin-drying device during production process of bottled shii-take sauce

A production process and technology of shiitake sauce, which is applied in the fields of application, food processing, food science, etc., can solve the problems of taking more time, uneven dehydration of shiitake mushrooms, increasing time cost and economic cost, etc., so as to improve the dehydration effect and avoid damage. , to prevent unintended effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

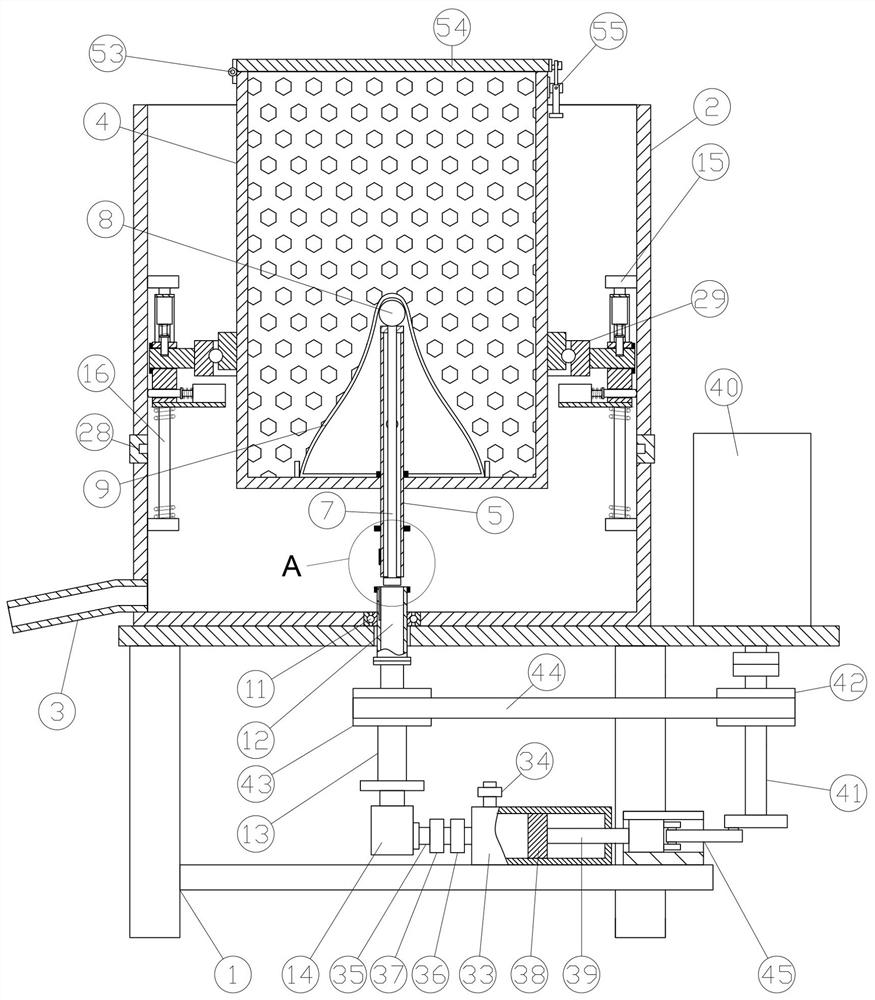

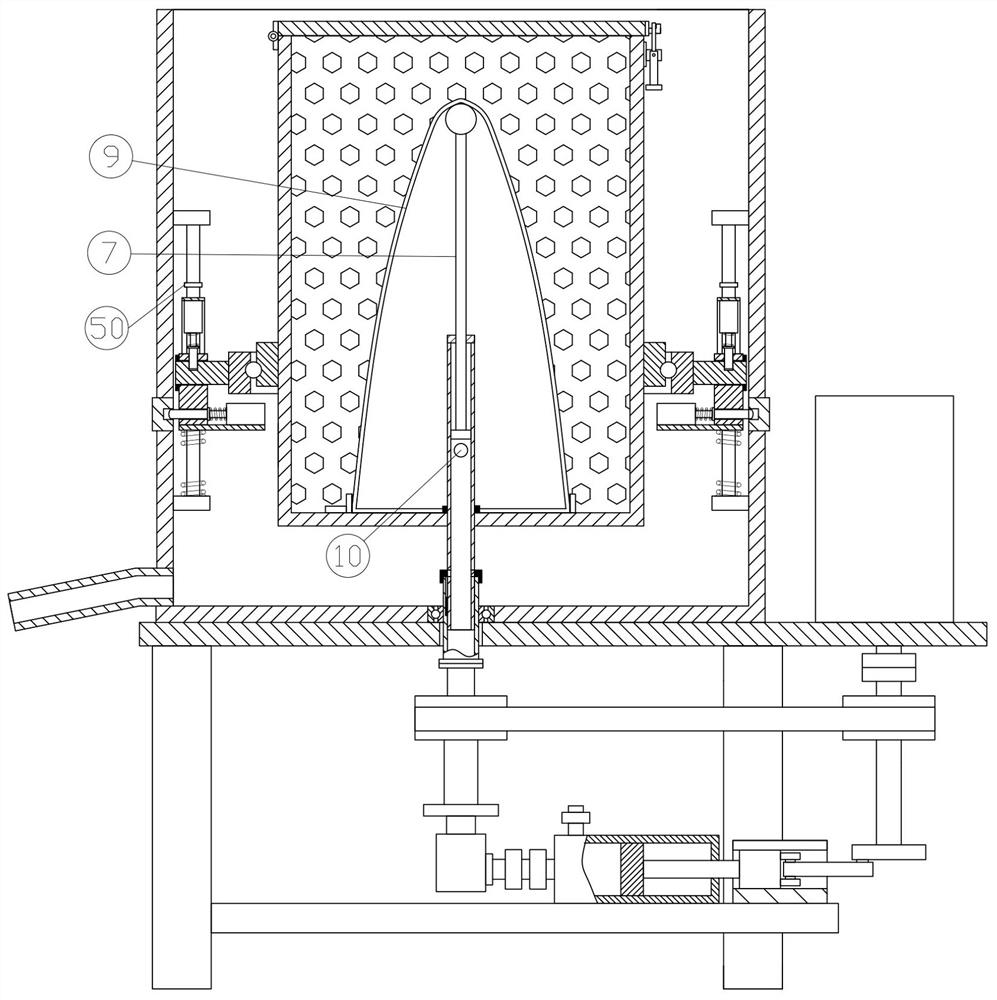

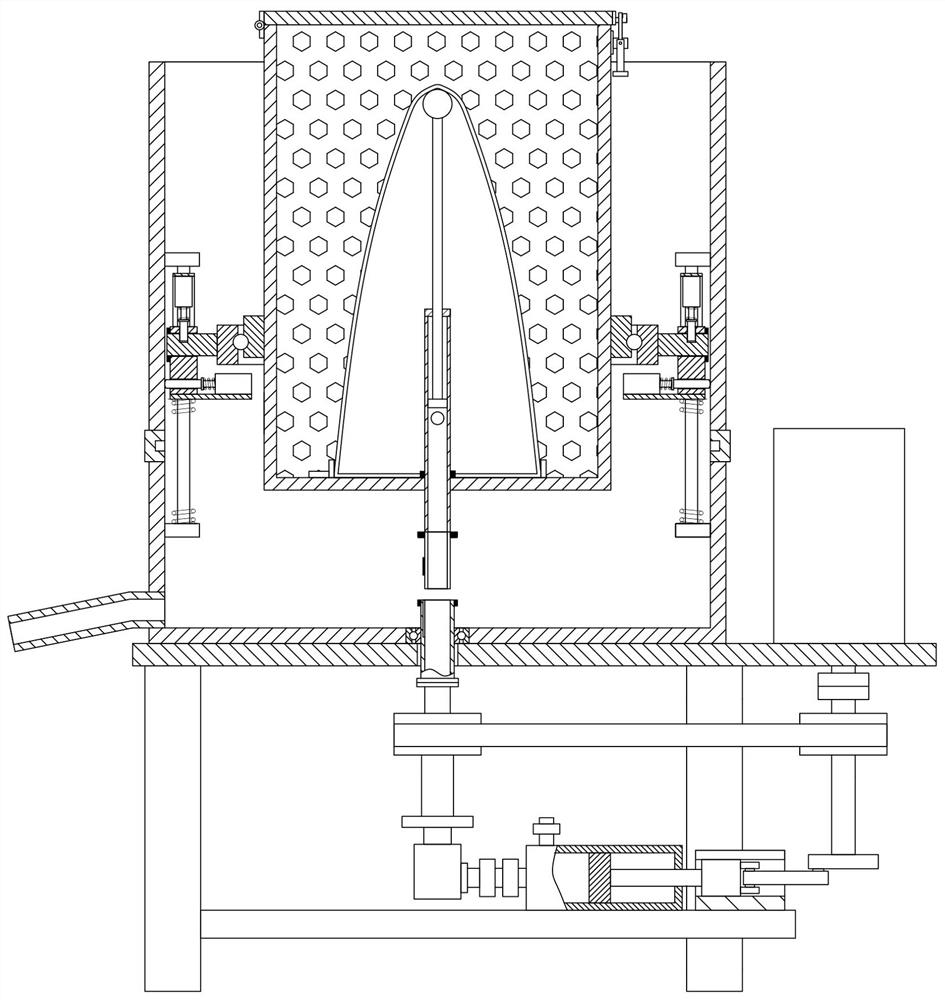

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8 Shown: a shiitake mushroom spin-drying device in the production process of bottled shiitake mushroom sauce, comprising a frame 1 and a cylindrical casing 2 fixedly installed on the frame 1, the side of the lower end of the casing 2 is provided with a drain 3, The centrifugal filter cartridge 4 is coaxially rotated inside the casing 2, and the bottom of the centrifugal filter cartridge 4 is coaxially fixed with an upper hollow sleeve 5. The upper hollow sleeve 5 is detachably connected with a jacking piston 6 for sliding and sealing cooperation with its inner wall. The upper end of the jacking piston 6 is fixed with a push rod 7, and the upper end of the push rod 7 protrudes from the upper hollow sleeve 5 and is equipped with a ball head 8. An air bag 9 is installed on the inner wall of the bottom end of the centrifugal filter cartridge 4, and the upper hollow sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com