Small-sized vibrating pulverizer for laboratory

A vibrating mill technology for laboratory use, applied in vibration suppression adjustment, mechanical equipment, grain processing, etc., can solve the problems of easily damaged internal structure of equipment, reduced equipment service life, complex structure of milling machine, etc., to prevent metal pollution , Avoid wear and tear, good vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The present application can be implemented in many different forms, and is not limited to the implementation manner described in this embodiment. The purpose of providing the following specific embodiments is to facilitate a clearer and more thorough understanding of the disclosure of the present application, wherein the words indicating orientation such as up, down, left, and right are only for the positions of the structures shown in the corresponding drawings.

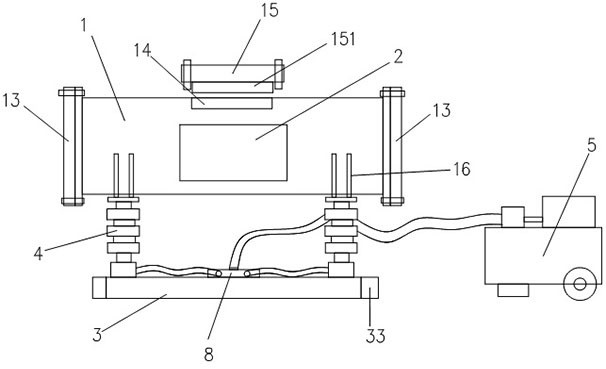

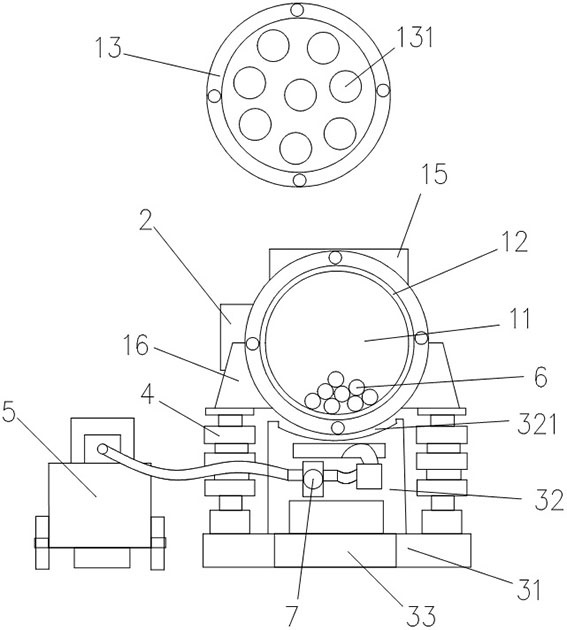

[0020] see Figure 1-2 As shown, the present invention relates to a small vibrating mill for laboratory use, including a vibrating shell 1, a vibrator 2, a chassis support 3, an air spring 4, and an air compressor 5, and the vibrating shell 1 is arranged on the chassis support 3 On the upper side, the left and right sides of the vibration shell 1 are connected to the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com