Centralized oil supply device for electric spark circulation filtering system

A technology of circulating filtration and centralized oil supply, which is used in attachments, electric processing equipment, metal processing equipment, etc., can solve the problems of large oil loss of EDM, poor filtering effect, and inability to filter EDM oil. Achieve the effect of reducing processing cost, excellent filtering effect and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

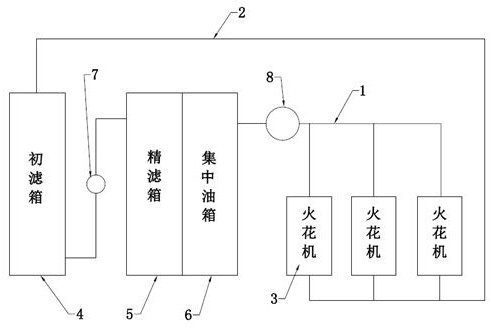

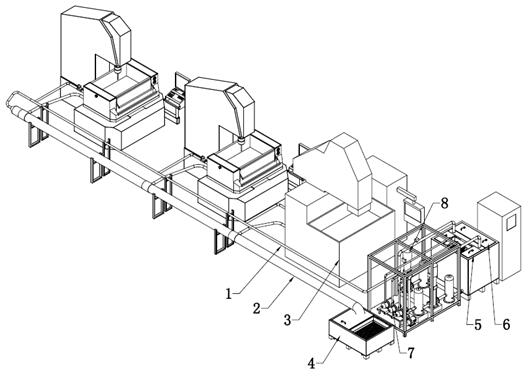

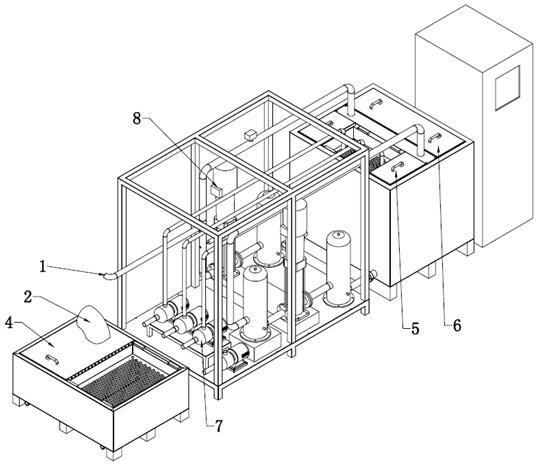

[0019] A centralized oil supply device for an electric spark circulation filter system, such as figure 1 as well as figure 2 As shown, it includes an oil supply pipe 1 and an oil return pipe 2, wherein the oil supply pipe 1 supplies oil to the spark machine 3, the oil supply pipe 1 can be connected with the oil pipes of multiple spark machines 3, and supplies oil to multiple spark machines 3 at the same time , in the embodiment of the present invention, the oil supply device is connected with the oil pipes of three spark machines 3, and can supply oil to three spark machines 3 at the same time; The oil return pipe of one spark machine 3 is connected, and finally the oil supply device can supply oil to multiple spark machines 3 and recover oil.

[0020] The oil supply device also includes a primary filter box 4, a fine filter box 5, and a centraliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com