Novel ultrahigh pressure plunger pump

An ultra-high pressure, plunger pump technology, applied in the direction of pumps, multi-cylinder pumps, pump devices, etc., can solve the problem of not meeting the working requirements of ultra-high pressure plunger pumps, insurmountable processing errors and assembly errors, fluid-solid-heat multi-field coupling effect enhancement and other problems, to achieve the effect of compact structure, improved service life and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, and the embodiments described here are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

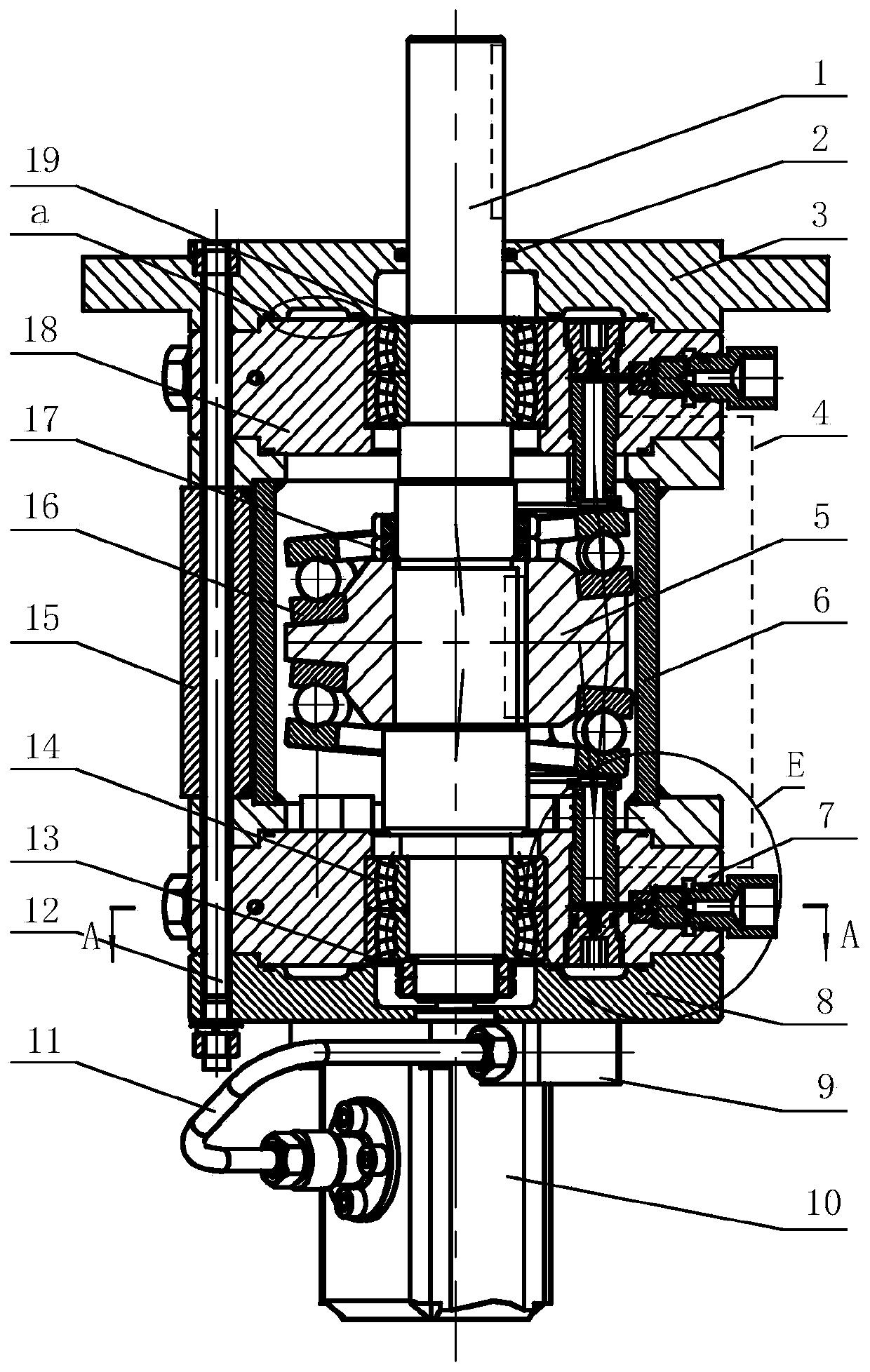

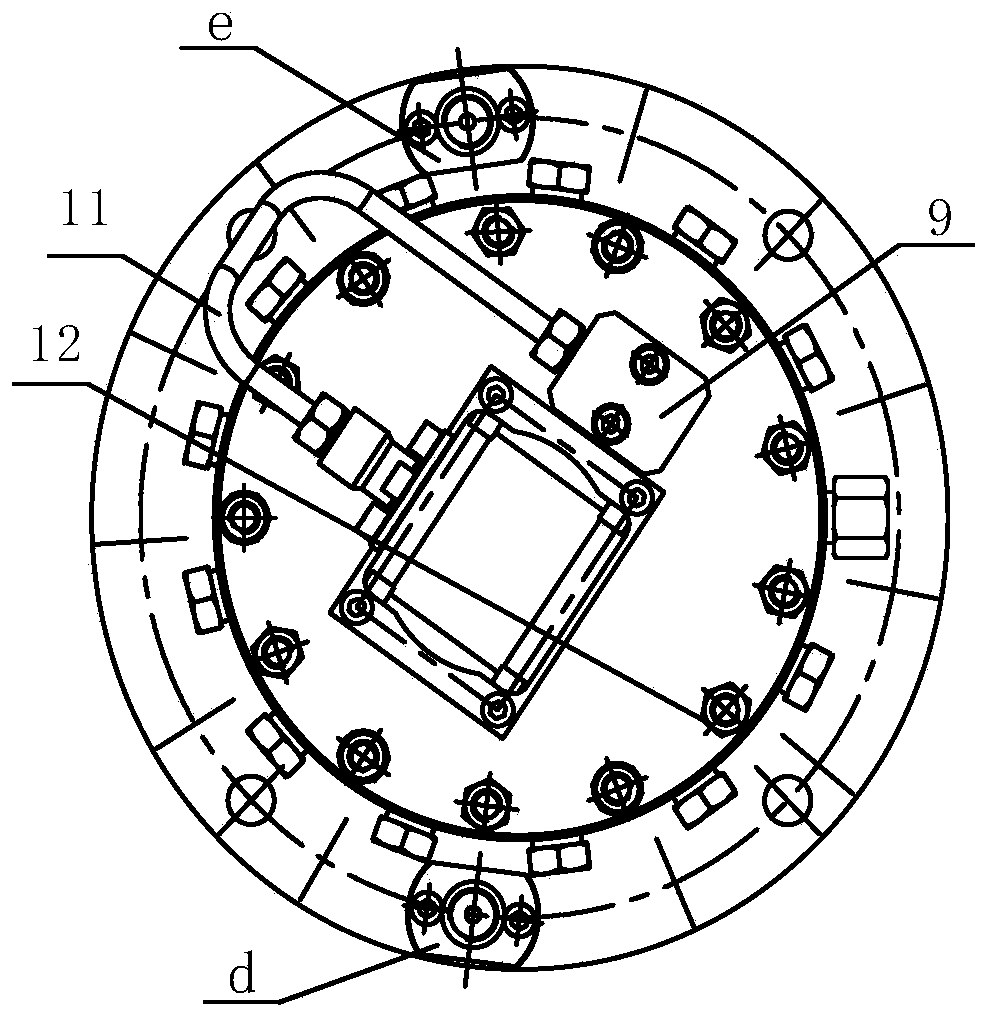

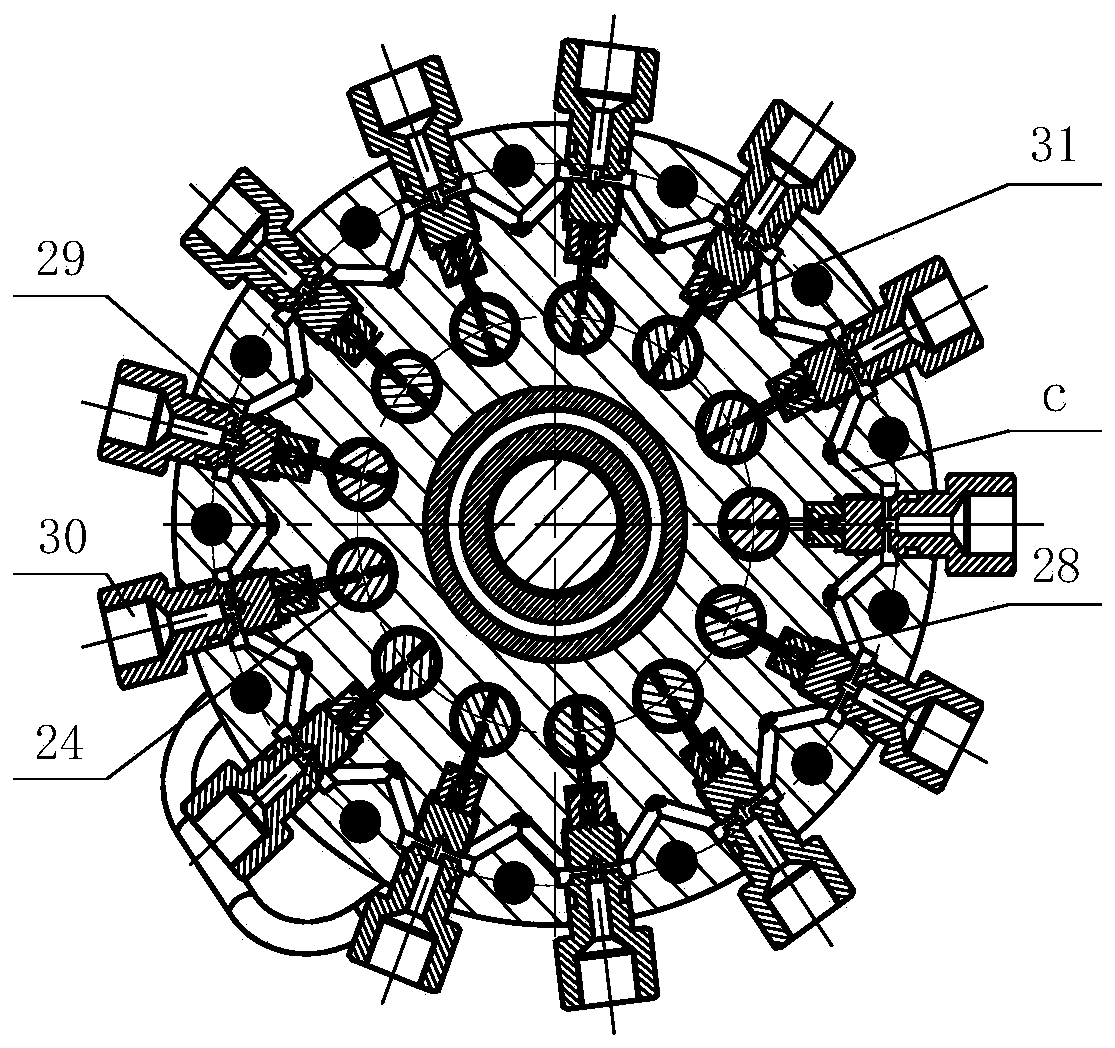

[0031] The present invention describes a new type of ultra-high pressure plunger pump, which includes a housing 6, which is relatively installed on the cylinder blocks at both ends of the housing 6, the main shaft 1 which runs through the cylinder and is placed inside the housing, and is installed coaxially with the main shaft 1 A double-sided balance swash plate 5 together; thrust ball bearings 16 are arranged on both sides of the double-side balance swash plate 5; a plurality of plungers squeezed by the thrust ball bearings 16 are evenly distributed radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com