Cold and heat adjustable type upper-air tower crane cab

A heating and cooling type, adjustable technology, applied in sustainable buildings, load suspension components, climate sustainability, etc., can solve problems such as insufficient supply of electricity and other equipment, unfavorable drivers for normal work, limited internal space, etc., to achieve savings Electric power consumption, convenient temperature adjustment, environmental protection and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

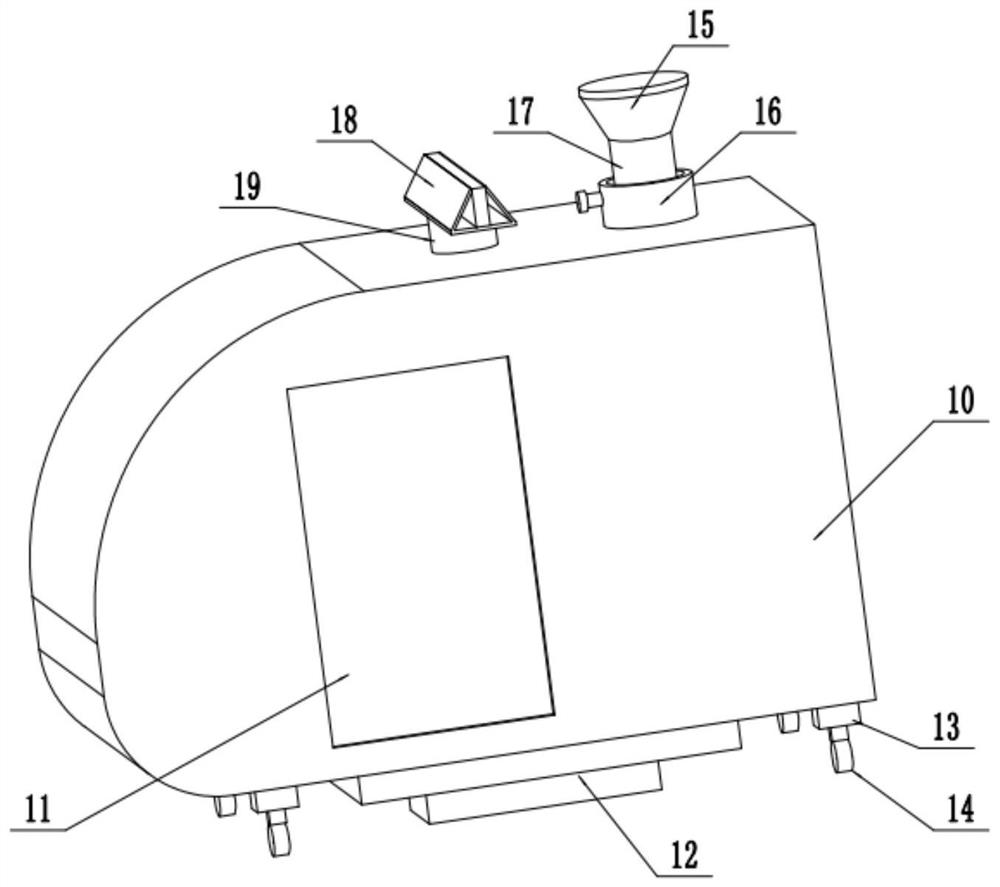

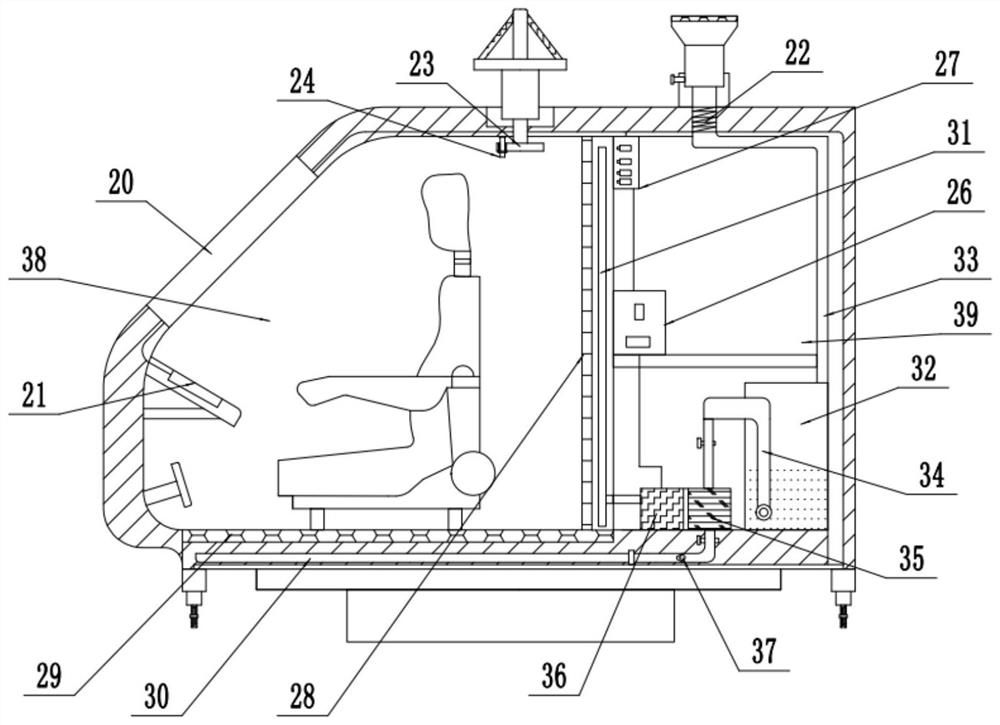

[0026] see Figure 1-5 , an adjustable heating and cooling type high-altitude tower crane cab, including a cockpit 10, the bottom of the cockpit 10 is fixedly installed on the top of the tower crane through a mounting plate 12, the left and right side walls of the cockpit 10 are hinged with doors 11, the cockpit 10 The upper part of the front side is provided with the glass window 20 which is convenient to observe the external situation of the rotating rod 19 which is inclined. The inner left side of the cockpit 10 is fixedly provided with a seat, and the inner wall of the cockpit 10 on the left side of the seat is provided with an operation panel 21 for controlling the operation of various components inside the rotating rod 19 . The inner side of the cockpit 10 is fixedly installed with a group of vertical baffles to divide the interior of the cockpit 10 into two areas, the left side is set as the driving space 38, and the right side is set as the heating and cooling space 39...

Embodiment 2

[0030] On the basis of Embodiment 1, the four corners of the lower surface of the cockpit 10 are fixedly installed with a wind generator 13 downwards, the wind generator 13 is electrically connected to the power storage box 27, and the bottom of the wind generator 13 is connected to a wind wheel. 14. Since the cockpit 10 is erected at a high altitude, it is usually under strong wind force, and then drives the wind wheel 14 to rotate to generate electricity through the wind generator 13, so as to make full use of natural resources to generate electricity and improve resource utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com