A kind of enhanced polycarboxylate water reducer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of water reducing agent to achieve the effects of improving compressive strength and flexural strength, enhancing adsorption capacity and improving water reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

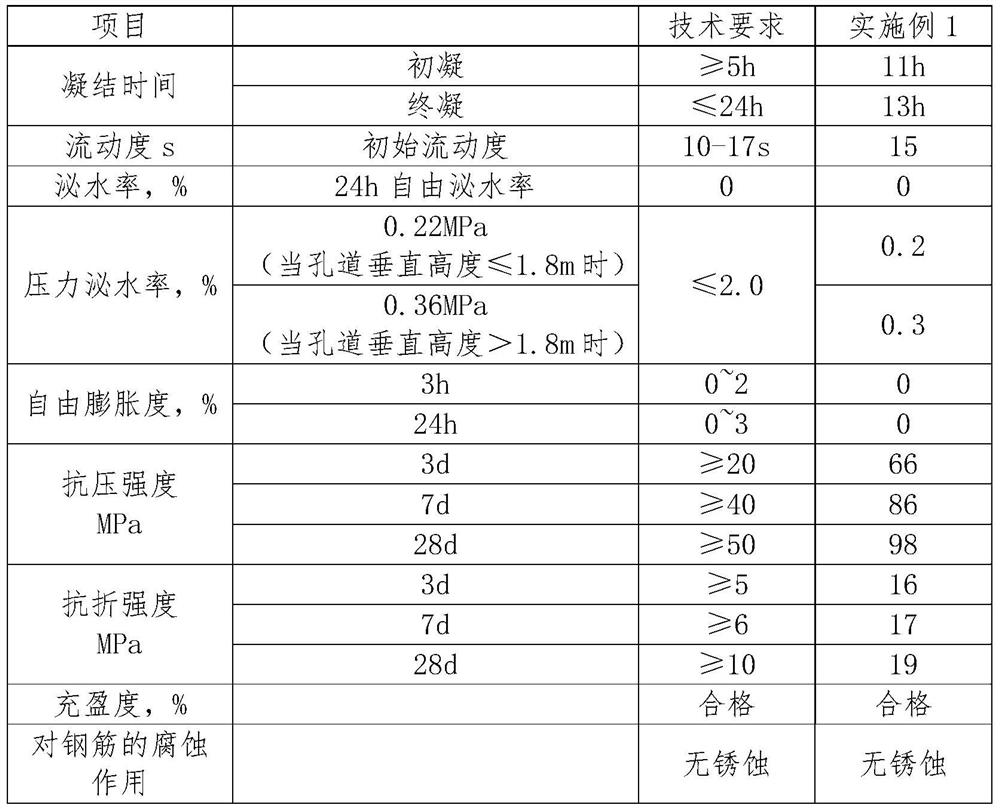

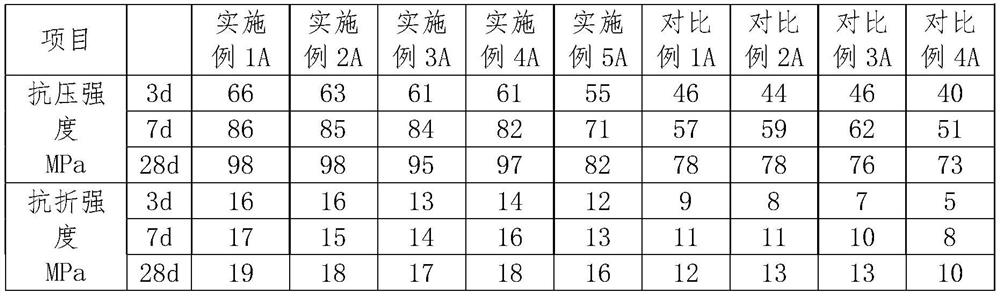

Examples

Embodiment 1

[0044] Add 1000g TPEG6000 and 1500g water into the reaction kettle, raise the temperature to 60°C, and stir evenly. In the reaction kettle, dropwise add 50g of ammonium persulfate aqueous solution containing 2wt% and 0.34g of dodecyl mercaptan at the same time, after 2 hours, the dropwise addition is completed, and the reaction is continued at 60°C for 1 hour;

[0045] In the reaction kettle, add 100g of acrylic acid, 150g of γ-methacryloxypropyltrimethoxysilane, 200g of 2wt% ammonium persulfate aqueous solution and 1.33g of dodecyl mercaptan dropwise at the same time, and the addition is completed in 3 hours , keep warm at 60°C and continue to react for 3 hours;

[0046] Mix 1000g TPEG600 with 1500g water evenly. While adding the homogeneous solution dropwise to the above reaction kettle, add dropwise 50 g of ammonium persulfate aqueous solution containing 2 wt %, and 0.33 g of dodecyl mercaptan, and finish adding dropwise in 3 hours, then keep warm at 60° C. and continue to...

Embodiment 2

[0051] Add 1500g TPEG8000 and 2250g water into the reaction kettle, raise the temperature to 55°C, and stir evenly. In the reaction kettle, dropwise add 50g of sodium persulfate aqueous solution containing 2wt% and 0.34g of cetyl mercaptan at the same time, after 2 hours, the dropwise addition is completed, and the reaction is continued at 55°C for 1 hour;

[0052] In the reactor, dropwise 100g methacrylic acid, 300g vinyl tris (b-methoxyethoxysilane), 200g aqueous solution of sodium persulfate containing 2wt% and 1.33g hexadecyl mercaptan, 3 hours After the dropwise addition is completed, the reaction is continued at 55° C. for 3 hours;

[0053] Mix 500g TPEG400 with 750g water evenly. While adding the homogeneous solution dropwise to the above-mentioned reaction kettle, add dropwise 50 g of an aqueous solution of sodium persulfate containing 2 wt % and 0.33 g of cetyl mercaptan, and complete the dropwise addition in 3 hours, and continue to react at 55° C. for 3 hours;

[...

Embodiment 3

[0058] Add 500g of TPEG4000 and 750g of water into the reaction kettle, raise the temperature to 60°C, and stir evenly. In the reaction kettle, dropwise add 50g of ammonium persulfate aqueous solution containing 2wt% and 0.34g of cetyl mercaptan at the same time, after 2 hours, the dropwise addition is completed, and the reaction is continued at 60°C for 1 hour;

[0059] In the reaction kettle, add 100g of itaconic acid, 200g of vinyltrimethoxysilane, 200g of 2wt% ammonium persulfate aqueous solution and 1.33g of hexadecyl mercaptan dropwise at the same time. After 3 hours, the dropwise addition is completed and the temperature is kept at 60°C to continue Reaction for 3 hours;

[0060] Mix 1500g TPEG800 with 2250g water evenly. While adding the homogeneous solution dropwise to the above-mentioned reaction kettle, add dropwise 50 g of ammonium persulfate aqueous solution containing 2 wt %, and 0.33 g of cetyl mercaptan, the dropwise addition is completed in 3 hours, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com