700-DEG-C boiler water wall arrangement structure capable of inhibiting negative flow response characteristics

A technology of response characteristics and layout structure, applied in boiler water pipes, steam boilers, steam boiler accessories, etc., can solve the risk of increasing local overtemperature of the cold wall, wall temperature deviation, and can not be very effective in suppressing flow and wall temperature deviation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with embodiment.

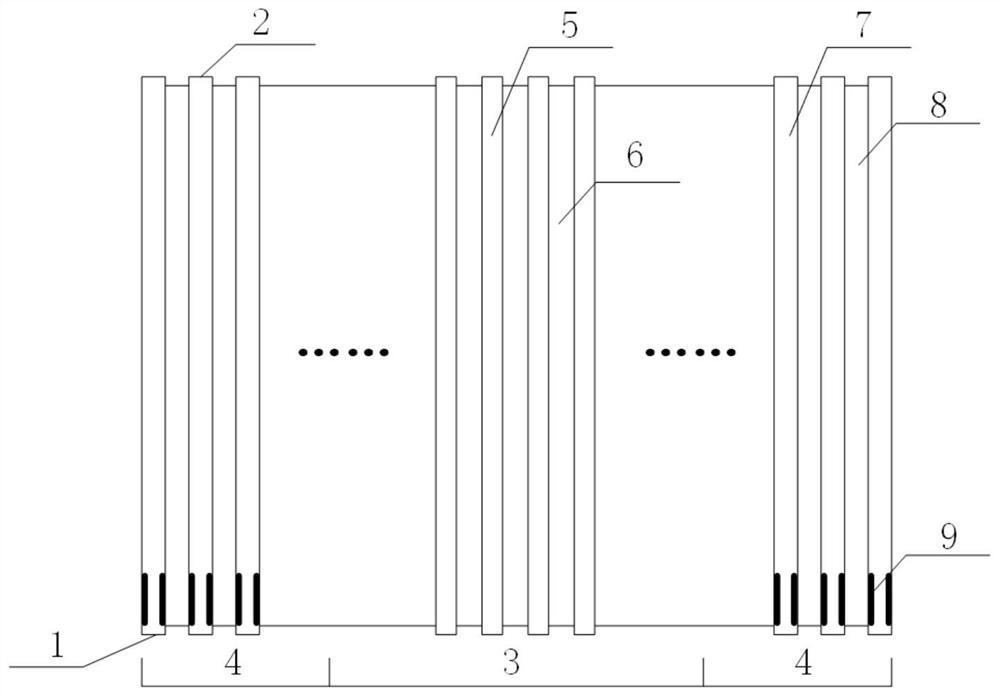

[0019] Such as figure 1 As shown, a 700°C ultra-supercritical boiler water-cooled wall arrangement that suppresses negative flow response characteristics is characterized in that it includes water-cooled wall tube inlet 1, water-cooled wall tube outlet 2, water-cooled wall 3 in the high heat load area, and water-cooled wall in the low heat load area. Wall 4, water wall tube 5 in high heat load area, water wall fin 6 in high heat load area, water wall tube 7 in low heat load area, water wall fin 8 in low heat load area, inlet throttle ring 9 for water wall tube in low heat load area.

[0020] The water-cooled wall is divided into water-cooled wall 3 in the high heat load area and water-cooled wall 4 in the low heat load area. The water-cooled wall 3 in the high heat load area is arranged in the middle of the water-cooled wall, and the water-cooled wall 4 in the low heat load area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com