High-voltage cable cross interconnection loop resistance live-line detection system and method

A technology of cross-connection and loop resistance, which is applied in the measurement of resistance/reactance/impedance, short-circuit test, impedance measurement, etc. It can solve the problems of inability to detect small-sized defects in metal connections, and the inability to detect high-voltage cable cross-connection loop resistance in a timely and accurate manner. , to achieve the effect of reducing cable failure rate, strong anti-interference function, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

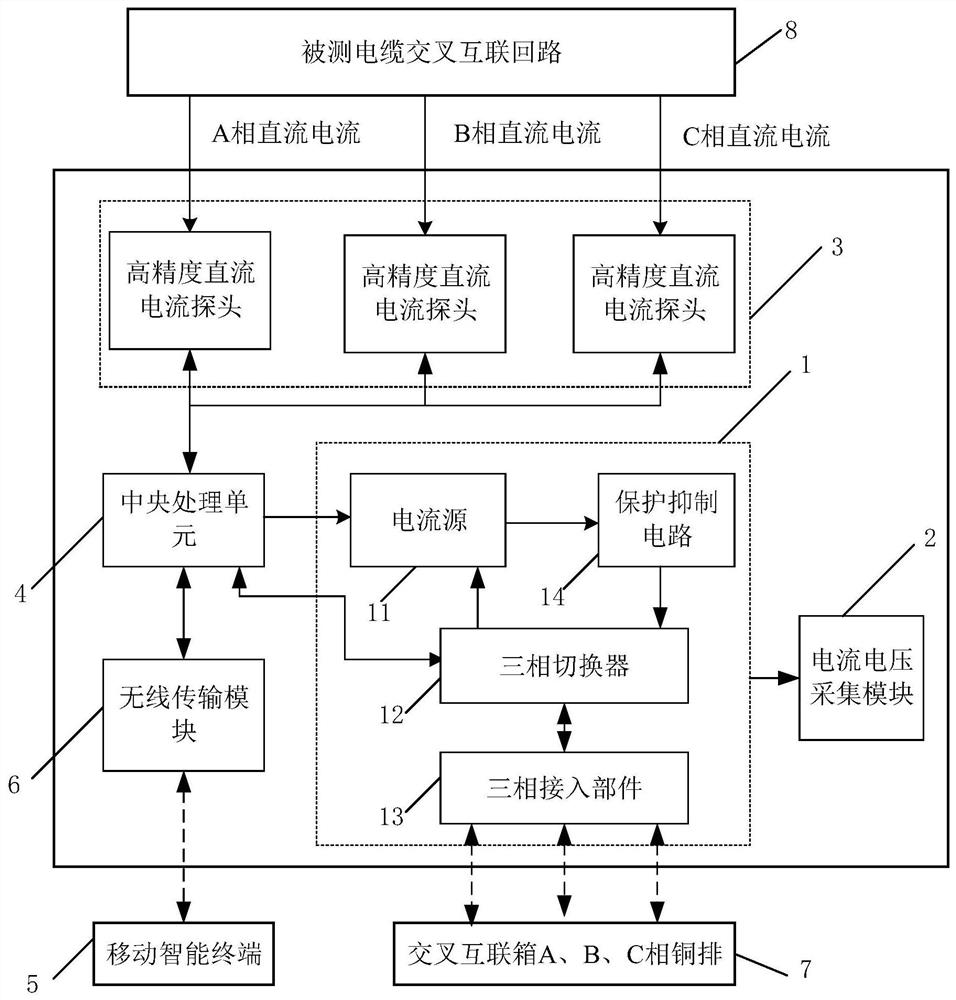

[0037] Such as figure 1 As shown, a high-voltage cable cross-connection loop resistance live detection system, the system includes:

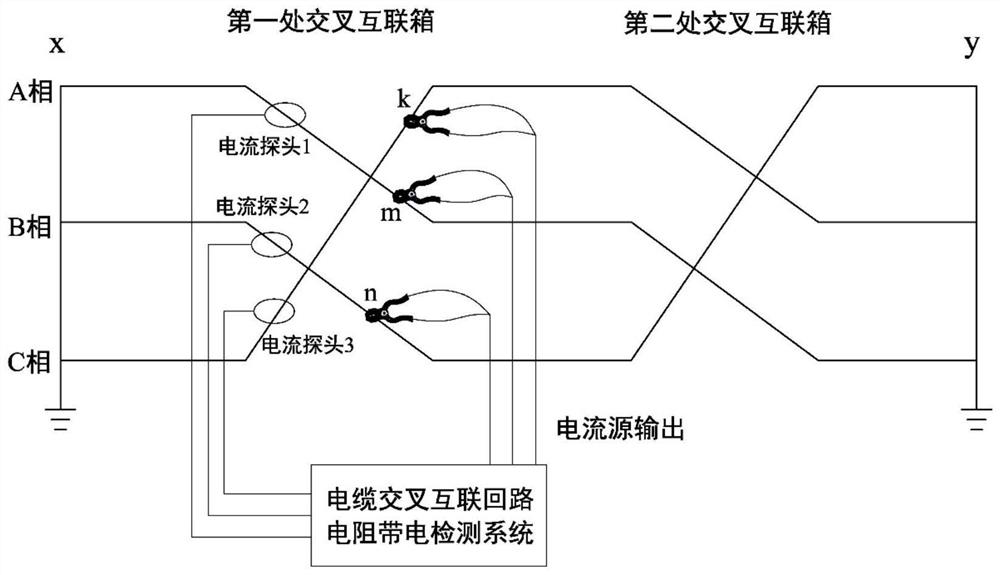

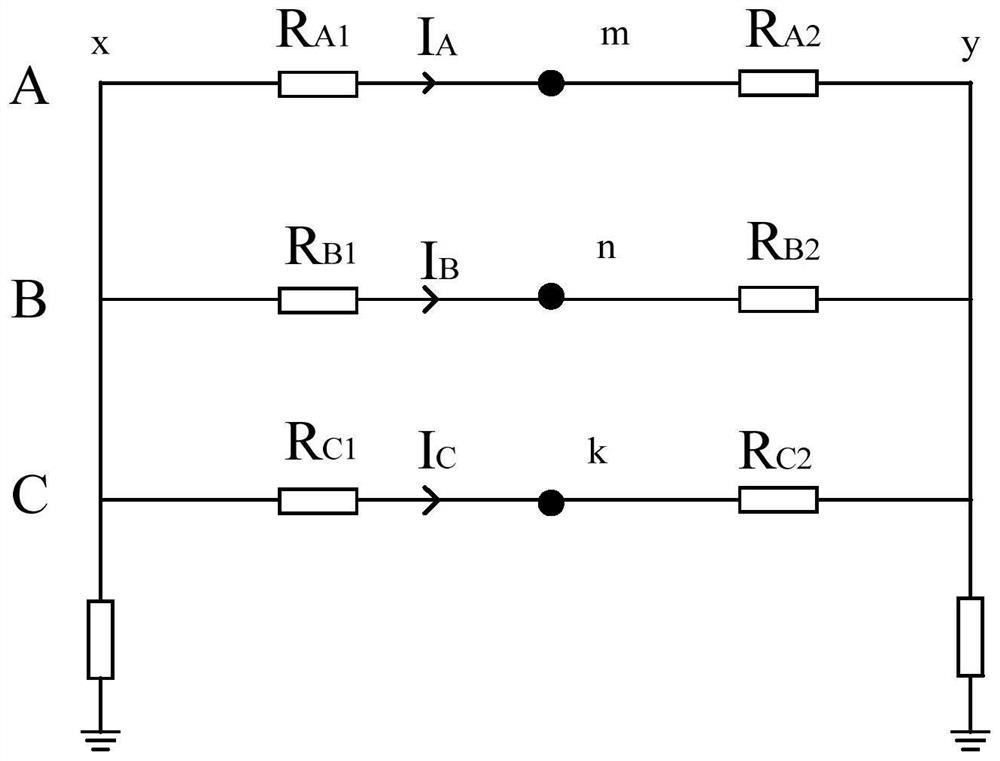

[0038] Current injection module 1: It is used to inject DC current into any two-phase metal sleeves of the A, B, and C three-phase cables of the high-voltage cable cross-connection loop on one side of the cross-connection box to form a current loop;

[0039] Current and voltage acquisition module 2: used to test the magnitude of the injected current and the voltage difference between the two-phase injection points forming the current loop when injecting direct current;

[0040] Loop DC current detection module 3: used to detect the magnitude of the DC current in the metal sleeves of the A, B, and C three-phase cables on the other side of the cross-connection box located on the grounding side of the high-voltage cable cross-connection loop when direct current is injected;

[0041] Central processing unit 4: used to control the switching of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com