Novel industrial robot servo driver electromagnetic compatibility test method

A technology of servo drive and industrial robot, applied in the field of servo drive, can solve the problems of servo drive equipment hardware and software system interference, affect the technological progress of servo drive equipment research and development, limit the stability and reliability of servo drive equipment, etc., to improve detection Operational efficiency and detection accuracy, reduced detection operation cost and labor intensity, and convenient detection data acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

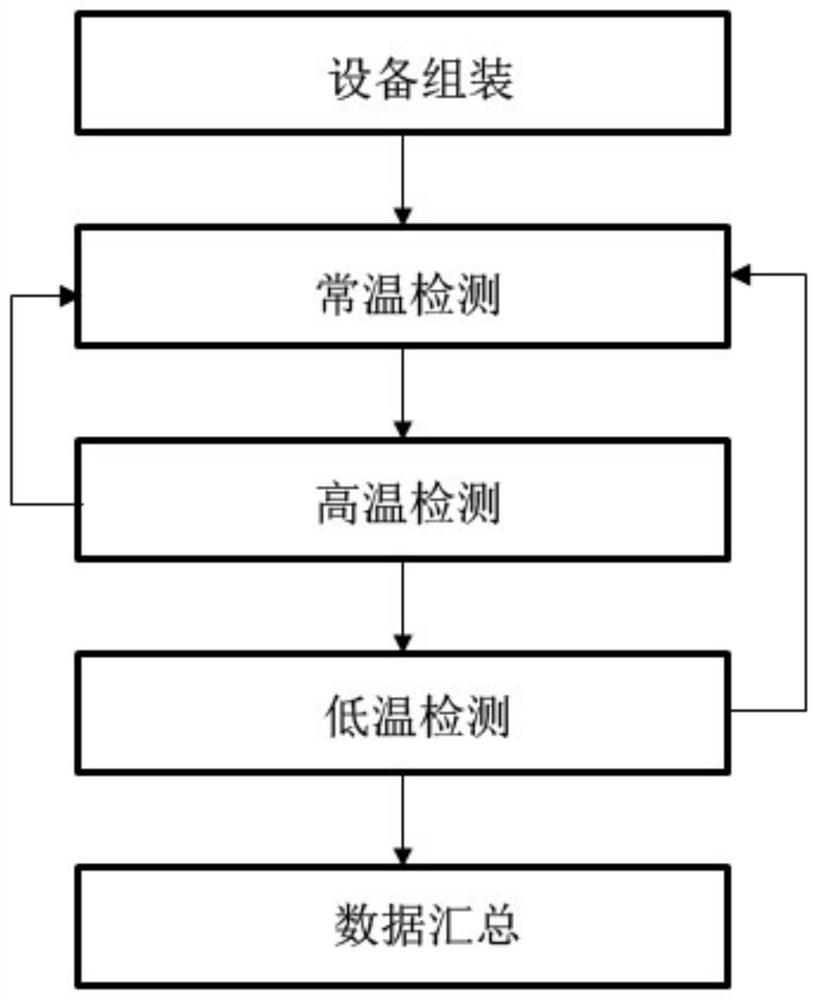

[0022] Such as figure 1 Shown is a new type of electromagnetic compatibility test method for industrial robot servo drives, including the following steps:

[0023] The first step is equipment assembly. First, install three servo drives with different capacities to be tested on the testing equipment, and electrically connect at least one servo motor to each other, and then connect the servo motor and the load matching its rated power to each other. , and then both the servo drive to be tested and the servo motor to be tested are covered with a sealed protective cover at the same time, and the servo drive to be tested and the servo motor to be tested are located in the same closed space, and then evenly distributed in the closed space at least two Electromagnetic radiation sources, and each electromagnetic radiation source is evenly distributed around each servo driver to be detected, and the axis of the electromagnetic radiation source is at an angle of 90° to the surface of th...

Embodiment 2

[0033] Such as figure 1 As shown, a new type of electromagnetic compatibility test method for industrial robot servo drives includes the following steps:

[0034] Assembling the equipment, first install three servo drives with different capacities to be tested on the testing equipment, and electrically connect at least one servo motor to each other, then connect the servo motor and the load matching its rated power to each other, and then connect the servo drives to be tested The tested servo drive and the test servo motor are covered with a sealed protective cover at the same time, and the servo drive to be tested and the test servo motor are located in the same closed space, and then at least two electromagnetic radiation sources are evenly distributed in the closed space , and each electromagnetic radiation source is evenly distributed around each servo driver to be tested, and the axis of the electromagnetic radiation source is at an angle of 45° to the surface of the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com