Battery replacement battery and battery replacement battery system

A technology of electric batteries and battery units, which is applied in the direction of battery/fuel cell control devices, batteries, secondary batteries, etc., which can solve problems such as difficult disassembly and transportation, large overall weight, high-intensity work and increased battery overheating accidents, and achieves easy Effect of mounting and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

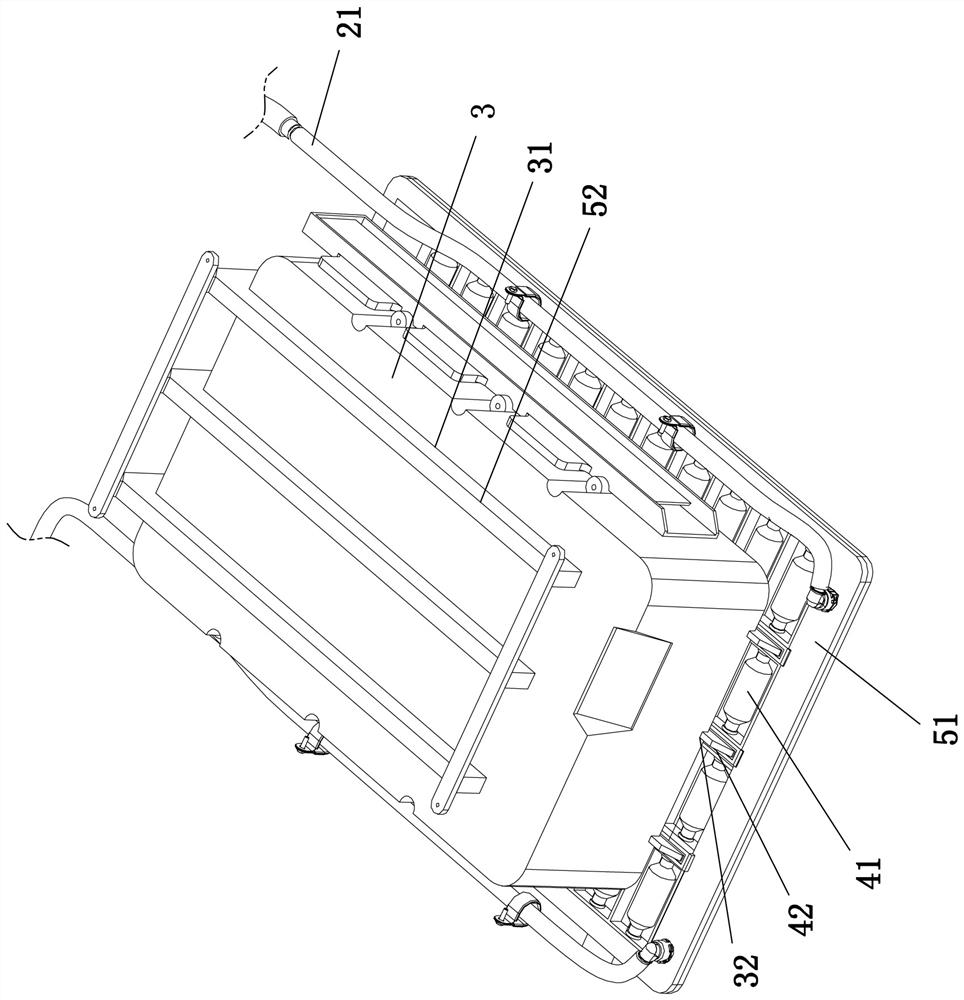

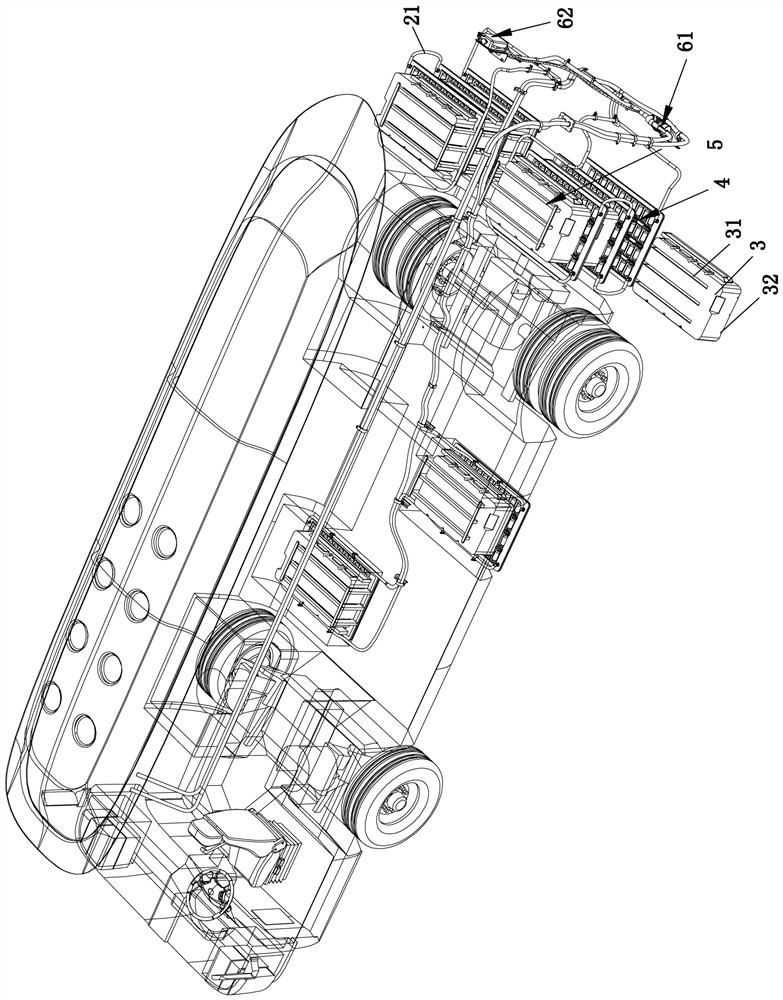

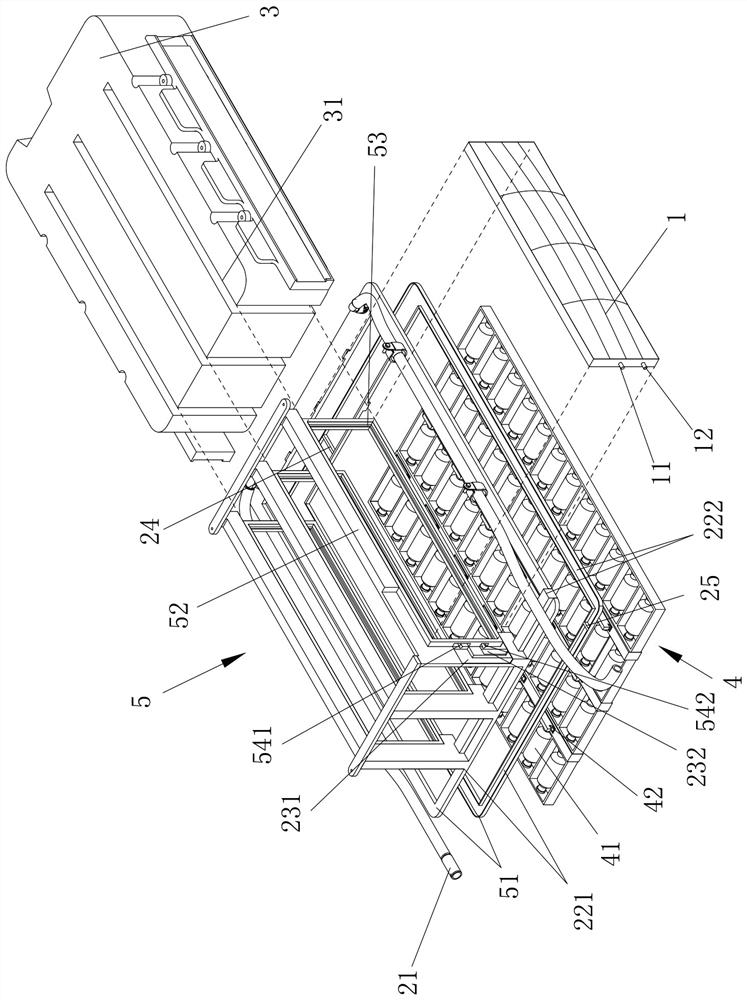

[0027] refer to figure 1 and figure 2 , a replacement battery, comprising a battery unit 3 and a heat dissipation unit, the heat dissipation unit includes a plurality of heat dissipation fins arranged at intervals, the heat dissipation unit is fixed on the vehicle body, and the battery unit 3 is provided with a plurality of heat exchange grooves 31; the battery unit 3 can be inserted It is mounted on the heat dissipation unit, and a heat dissipation fin is detachably inserted in each heat exchange slot 31 . Specifically, the groove direction of the heat exchange groove 31 is consistent with the length direction of the heat dissipation fins, so as to realize the sliding fit between the heat dissipation unit and the battery unit during the insertion and removal process.

[0028] refer to figure 1 and figure 2 , the heat dissipation unit includes a bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com