Activity regeneration method for Pt-based catalyst for preparing propylene through propane dehydrogenation

A propane dehydrogenation and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

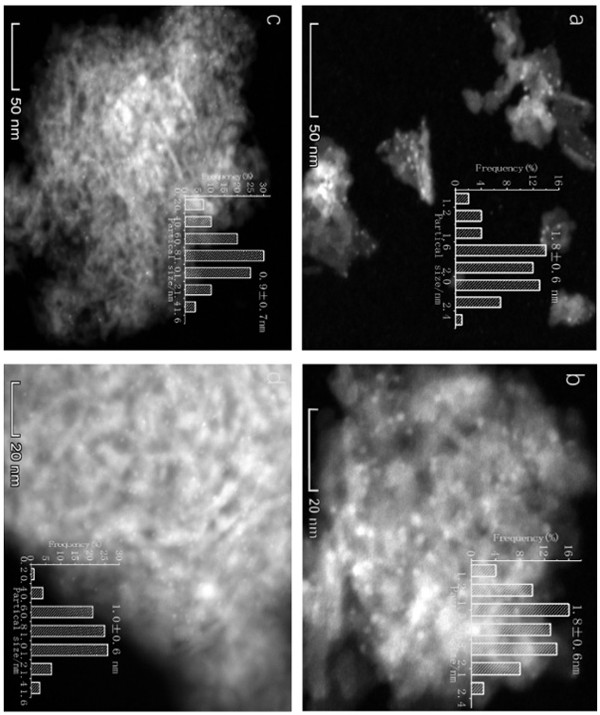

Image

Examples

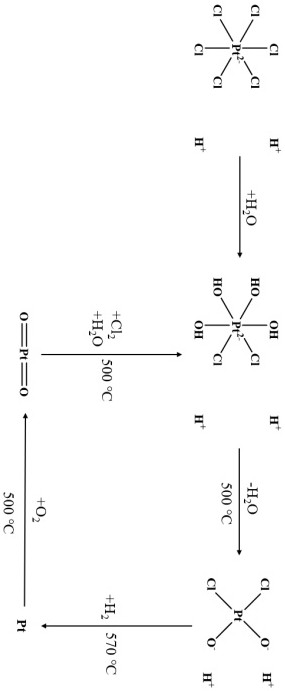

Embodiment 1

[0032] Fill 100 mg Pt-Sn / θ-Al in a fixed-bed tubular reactor 2 o 3 , the reactant is propane, the reaction temperature is 570°C, the reaction pressure is normal pressure, and the propane weight hourly space velocity is 7 h -1 , when the ratio of hydrogen to hydrocarbon was 1, the initial propane conversion rate was 40.5%, and the selectivity was 96.1%. After 16 h of reaction, the propane conversion rate was 28.7%, and the propane selectivity was 98.0%. The reacted catalyst was packed in a fixed-bed tubular reactor, and air was introduced to raise the temperature to 350 °C at a heating rate of 2.5 °C / min, and roasted for 30 min to remove carbon deposits, and then HCl was introduced with a volume concentration of 0.2% and a flow rate of 80 mL / min of HCl / air mixture, the temperature was raised to 360 °C at a heating rate of 2.5 °C / min, after 2 h of treatment, the introduction of HCl was stopped, and it was naturally cooled to room temperature. The treated catalyst was reduced i...

Embodiment 2

[0034] Fill 100 mg Pt-Sn / θ-Al in a fixed-bed tubular reactor 2 o 3 , the reactant is propane, the reaction temperature is 570°C, the reaction pressure is normal pressure, and the propane weight hourly space velocity is 7 h -1 , when the hydrogen-to-hydrocarbon ratio was 1, the initial propane conversion rate was 41.0%, and the selectivity was 96.5%. After 16 hours of reaction, the propane conversion rate was 29.3%, and the propane selectivity was 98.4%. The reacted catalyst was packed in a fixed-bed tubular reactor, and air was introduced to raise the temperature to 350 °C at a heating rate of 2.5 °C / min, and roasted for 30 min to remove carbon deposits, and then HCl was introduced with a volume concentration of 0.9 % and a flow rate of 80 mL / min of HCl / air mixture, the temperature was raised to 360 °C at a heating rate of 2.5 °C / min, after 2 h of treatment, the introduction of HCl was stopped, and it was naturally cooled to room temperature. The treated catalyst was reduced...

Embodiment 3

[0036] Fill 100 mg Pt-Sn / θ-Al in a fixed-bed tubular reactor 2 o 3 , the reactant is propane, the reaction temperature is 570°C, the reaction pressure is normal pressure, and the propane weight hourly space velocity is 7 h -1 , when the hydrogen-to-hydrocarbon ratio was 1, the initial propane conversion rate was 40.0%, and the selectivity was 95.9%. After 16 hours of reaction, the propane conversion rate was 30.5%, and the propane selectivity was 98.2%. The reacted catalyst was packed in a fixed-bed tubular reactor, and air was introduced to raise the temperature to 350 °C at a heating rate of 2.5 °C / min, and roasted for 30 min to remove carbon deposits, and then HCl was introduced with a volume concentration of 0.2% and a flow rate of 80 mL / min of HCl / air mixture, the temperature was raised to 400 °C at a heating rate of 2.5 °C / min, after 2 h of treatment, HCl was stopped, and it was naturally cooled to room temperature. The treated catalyst was reduced in a hydrogen atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com