Cleaning equipment for construction waste

A technology for cleaning equipment and construction waste, applied in grain processing, using liquid separating agent, grading, etc., can solve the problems of reducing grinding efficiency, high labor intensity, manpower and physical strength, etc., and achieve the effect of reducing grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

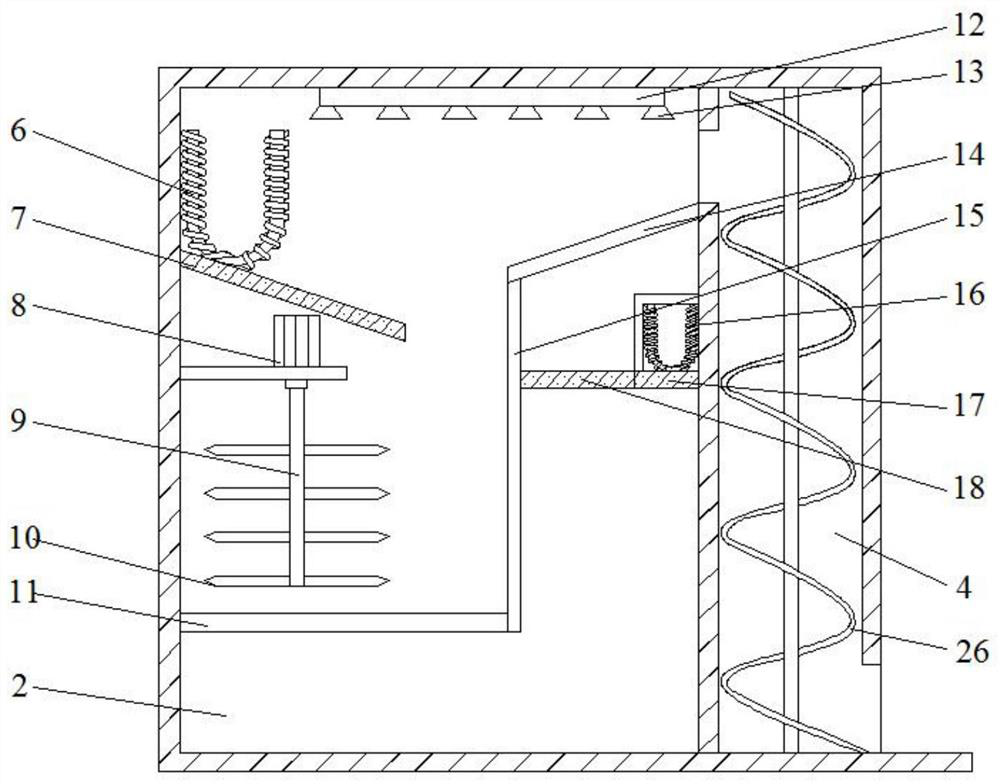

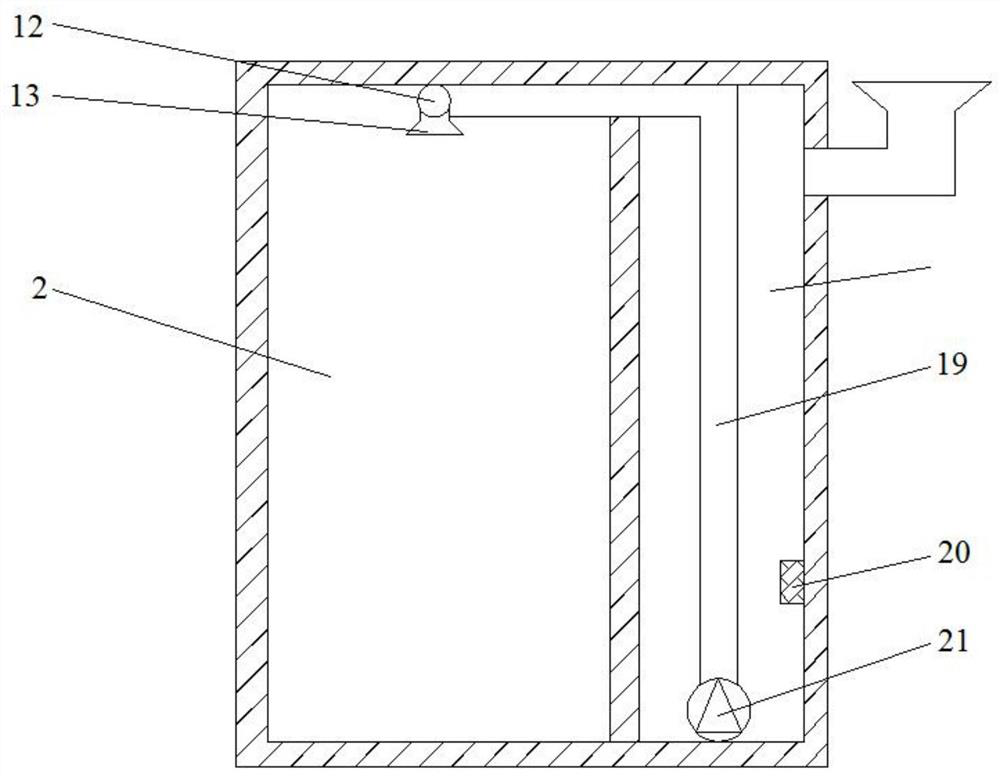

[0030] refer to Figure 1-4 , a cleaning device for construction waste, comprising a water tank 1, a processing chamber 2 and a lifting chamber 4, the upper part of the inner wall of the processing chamber 2 near the lifting chamber 4 is provided with a screening mechanism for screening the volume of garbage, and the processing chamber 2 is far away from the lifting chamber The upper part of one side of the inner wall of 4 is provided with a first sorting mechanism for sorting large pieces of metal and other large pieces of garbage, and the bottom of the screening mechanism is provided with a second sorting mechanism for sorting small pieces of metal and other small pieces of garbage. The bottom of the mechanism is provided with a rotating shaft 9, on which a plurality of crushing knives 10 are welded, the top of the rotating shaft 9 is provided with a rotating mechanism that drives the rotating shaft 9 to rotate, and the inner wall of the processing chamber 2 below the crushin...

Embodiment 2

[0035] refer to Figure 5-6 The only difference between this embodiment and Embodiment 1 is that the rotating mechanism includes an electric telescopic rod 22, a rotating disk 23, a limit frame 24, and a protruding rod 25, and a mounting plate is welded on the inner wall of the processing chamber 2 below the first iron plate 7. The electric telescopic rod 22 is horizontally installed on the top of the mounting plate, the top of the telescopic end of the electric telescopic rod 22 is welded to the side of one end of the limit frame 24, the protruding rod 25 is slidably connected to the inside of the limit frame 24, and both sides of the top of the mounting plate are welded Limiting blocks, the two ends of the limiting frame 24 are respectively slidably connected to the two limiting blocks, the bottom end of the protruding rod 25 is welded to the top edge of the turntable 23, the turntable 23 is connected to the mounting plate in rotation, and the rotating shaft 9 is welded to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com