ACF pasting device of liquid crystal display ACF pressing and pasting equipment and using method thereof

A liquid crystal display and pasting device technology, which is applied to lighting and heating equipment, transportation and packaging, conveyor objects, etc., and can solve problems such as difficulty in pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

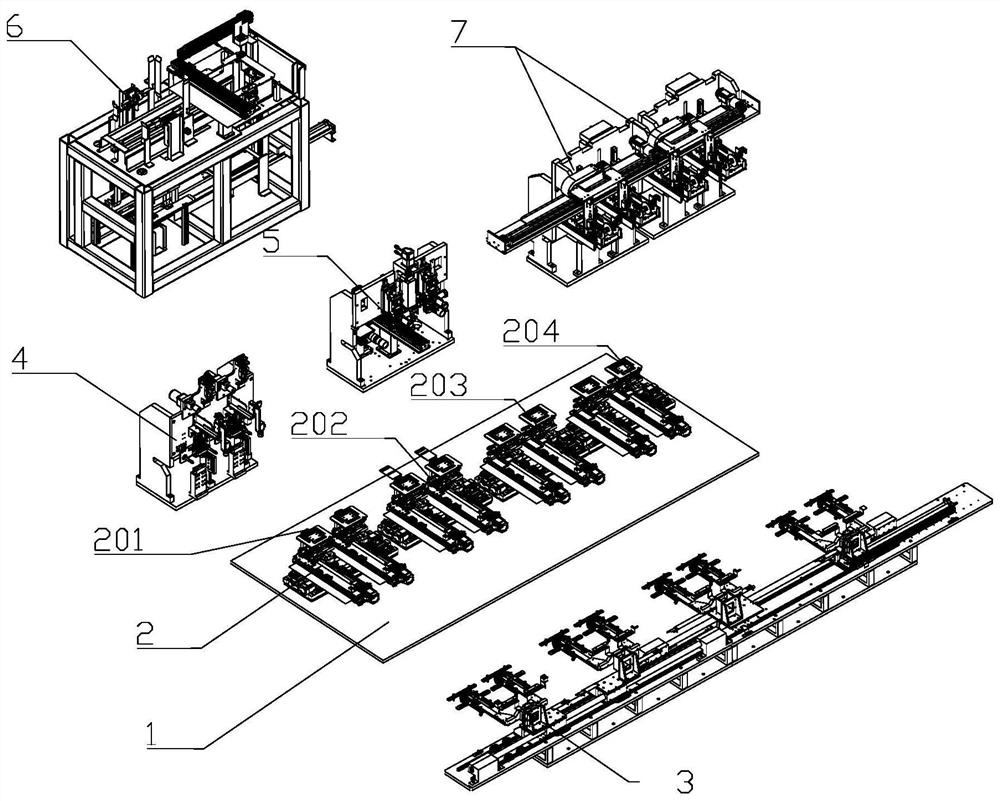

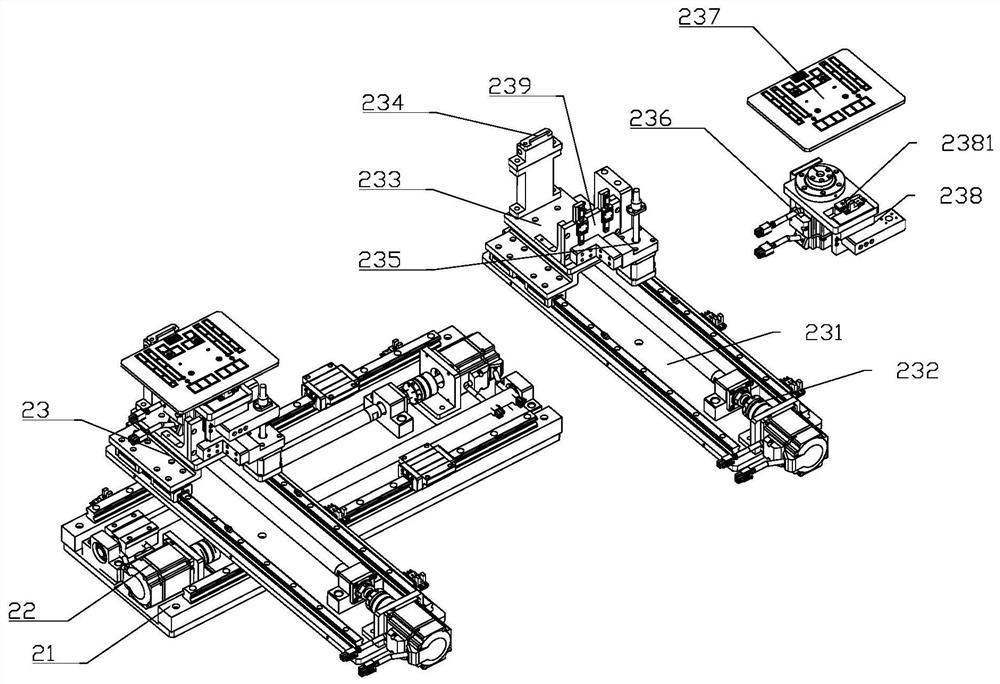

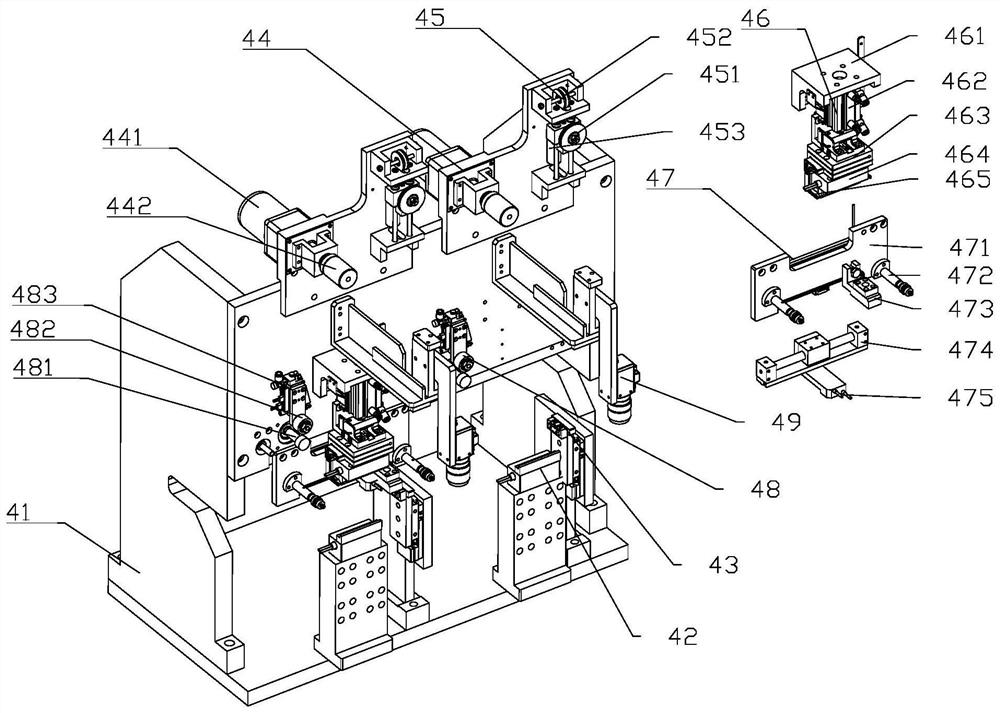

[0024] Such as figure 1 As shown, a liquid crystal display ACF pressing equipment includes a frame 1 and a display feeding device, a fixture device 2, a transfer device 3, an ACF pasting device 4, and a cable pre-pressing device installed on the frame 1. 5. The arranging wire feeding device 6, the pressing device 7 and the discharging device; the jig device 2 is arranged in multiple groups side by side, and the jig device 2 corresponds to the ACF pre-pressing station 201 and the arranging wire pre-pressing station Position 202, the first primary pressing station 203, and the second primary pressing station 204; the transfer device 3 corresponds to the side of the transfer device 3; along the processing direction, the display screen feeding device, ACF paste The device 4, the cable pre-pressing device 5 and the pressing device 7 are arranged in sequence. The ACF pasting device 4 corresponds to the ACF pre-pressing station 201, and the cable pre-pressing device 5 corresponds to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com