Oil inlet and outlet hole of inner cooling oil channel of steel piston

A technology of entering and exiting oil holes and steel pistons, applied in the directions of pistons, engine components, machines/engines, etc., can solve the problems of low oil capture efficiency, fast oil outflow, and failure to lubricate the connecting rod bushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

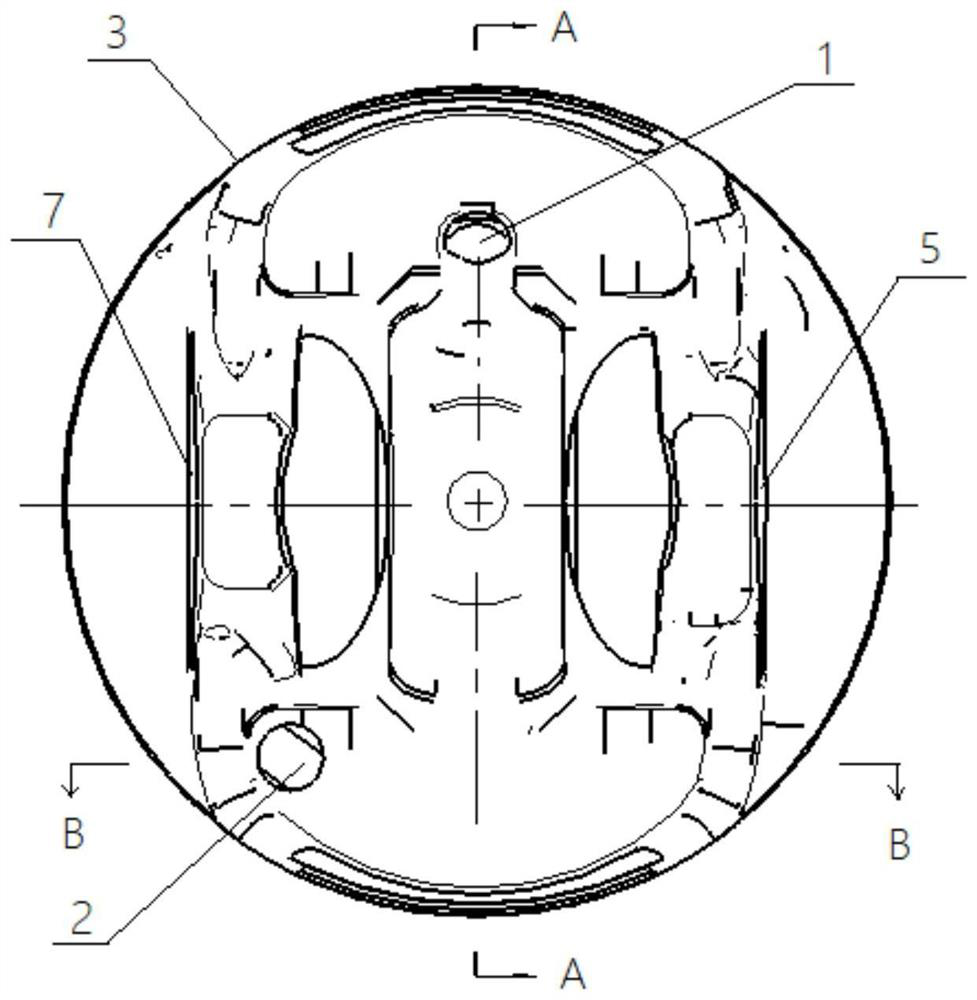

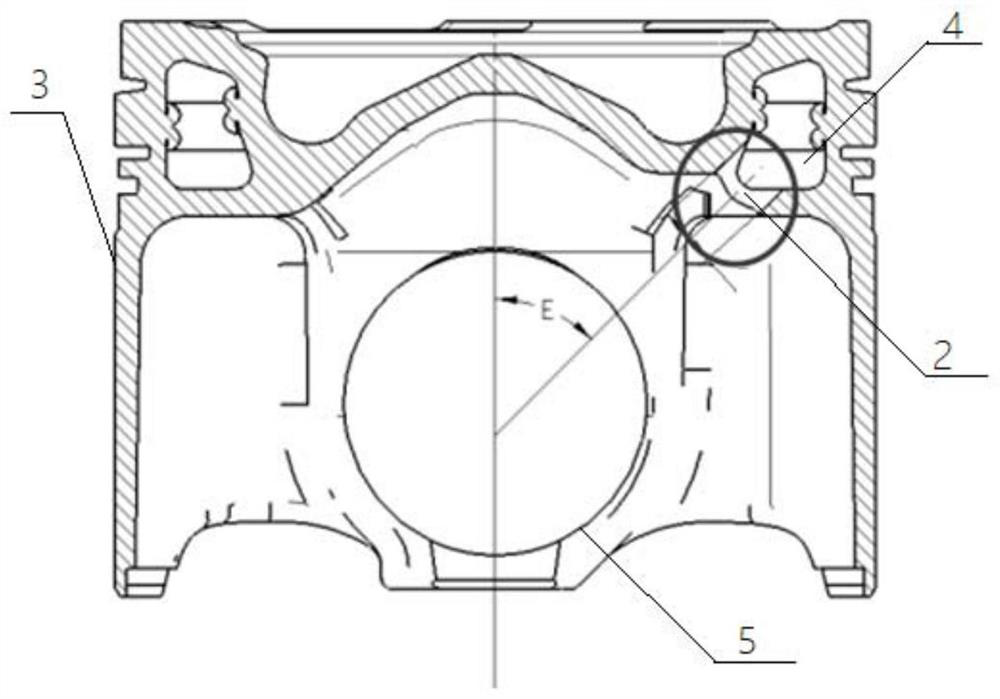

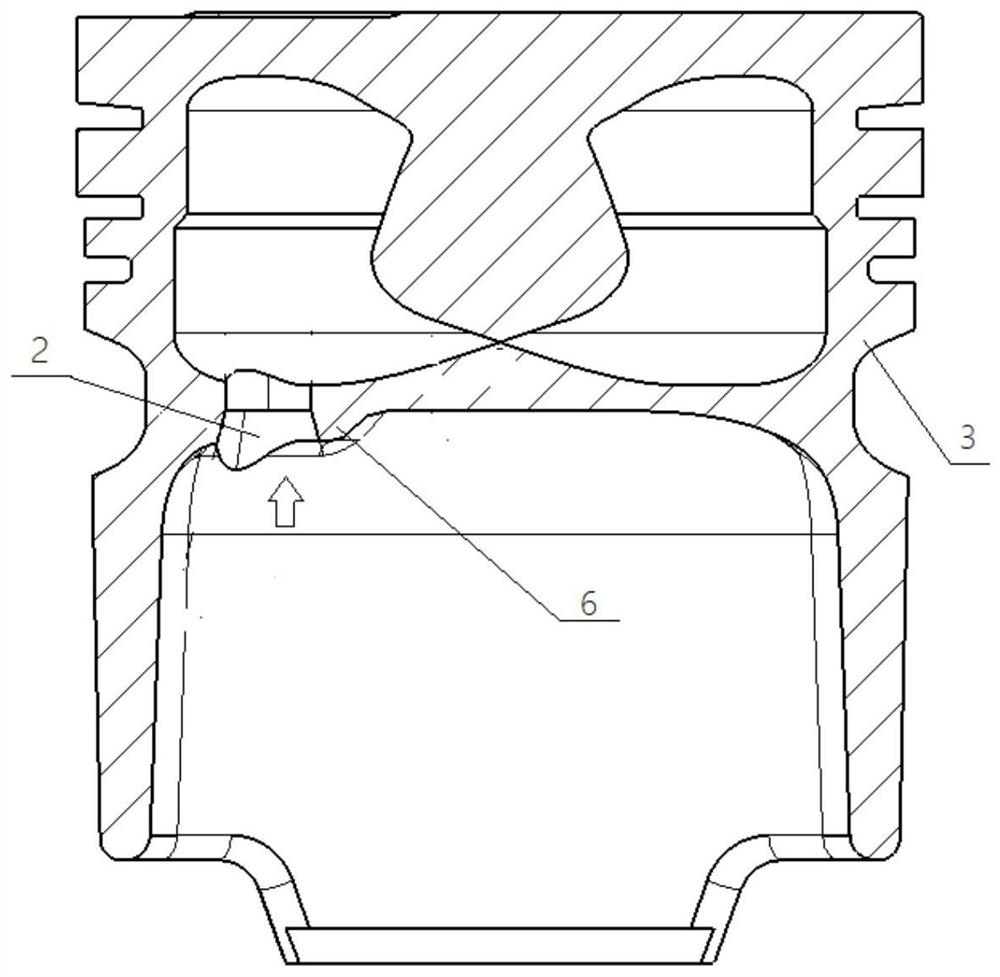

[0017] Such as Figure 1-3 As shown, the present invention provides a steel piston internal cooling oil channel inlet and outlet oil hole, including a piston body 3, a left pin hole 7 and a right pin hole 5 are arranged on the piston body 3, and an inner pin hole 5 is provided in the piston body 3. The cooling oil passage 4 also includes an oil outlet hole 1 and an oil inlet hole 2 on the internal cooling oil passage 4, and the oil outlet hole 1 is arranged in the direction of the perpendicular line between the centers of the left pin hole 7 and the right pin hole 5, And the range of the included angle E formed by the axis of the oil outlet hole 1 and the vertical direction is 40-50°, the engine oil stays in the cooling oil passage in the piston for a long time and absorbs more heat. And when the included angle E is 45°, the effect is better. The oil inlet hole 2 is provided with a flat boss, which can thicken the wall of the inner cavity, and then the diameter of the oil inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com