Method for changing steam feed pump system into full-variable-frequency high-rotating-speed electrically-driven feed pump system and brand-new logic control system of full-variable-frequency high-rotating-speed electrically-driven feed pump system

A technology of electric feed water pump and steam feed water pump, which is applied in the direction of pump control, water supply control, pump, etc., and can solve problems such as poor accuracy, operation safety failure, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

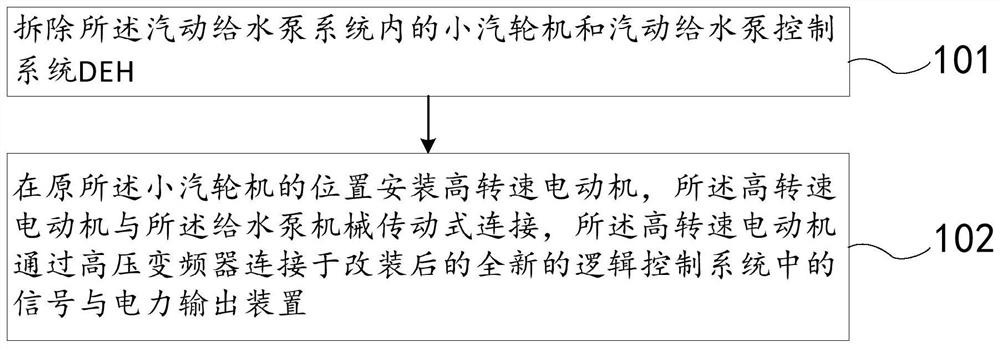

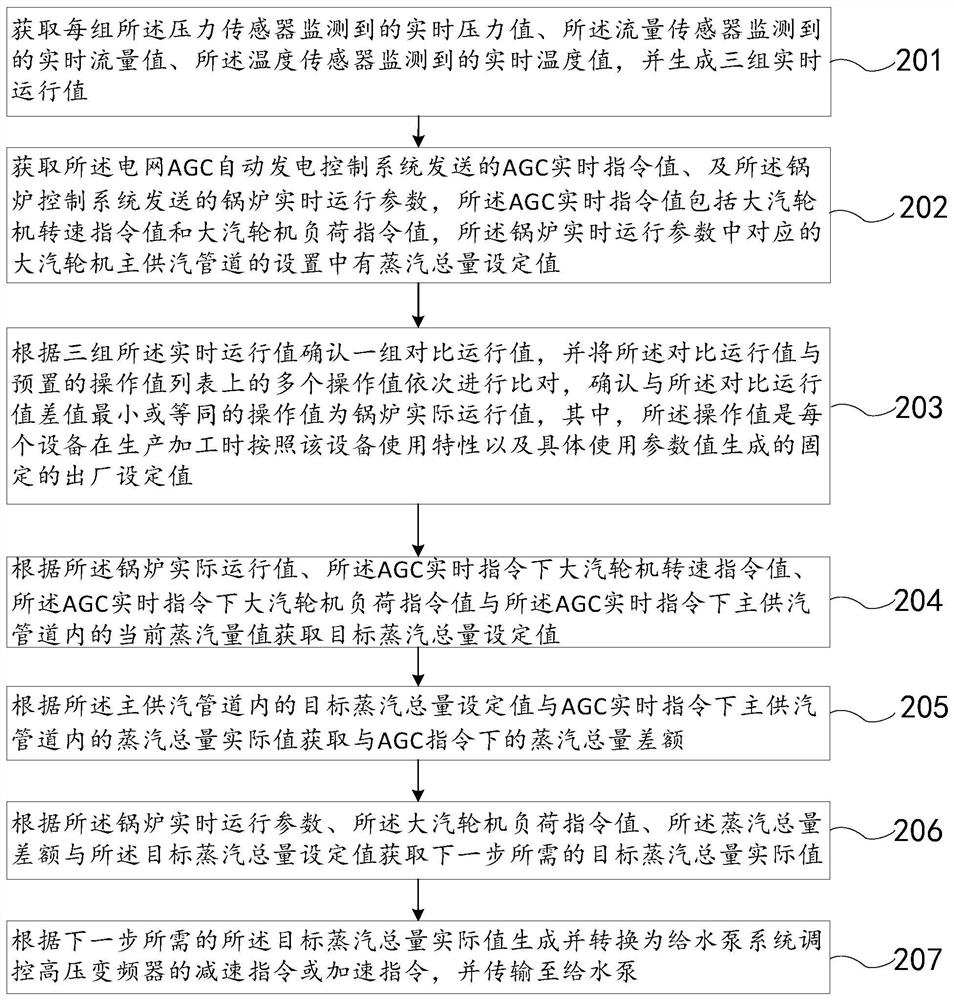

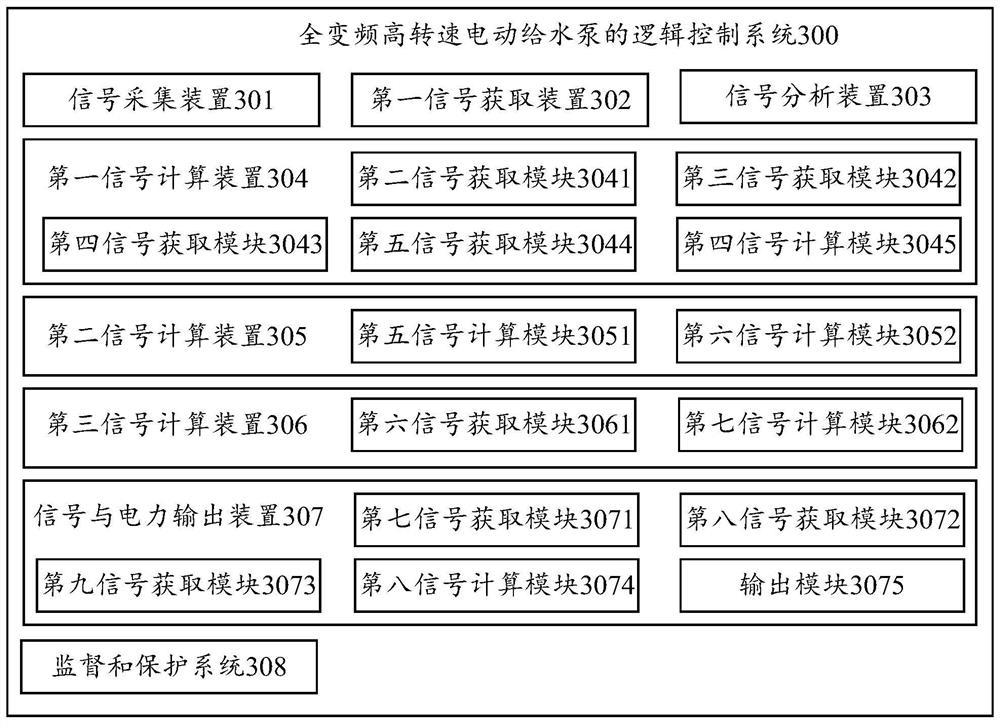

Method used

Image

Examples

Embodiment 1

[0139] Embodiment 1, the main structure of the hardware of the steam-operated water feed pump 315 composed of two 50% capacity feed water pumps 315 is: there are two small steam turbines to respectively drive a 50% capacity water feed pump 315 to work, this kind of structure According to the different positions of the front pump 316 configured in the system, it is also divided into Type A and Type B.

[0140] Type A:

[0141] The structure of the original A-type steam-driven feed water pump consisting of two 50% capacity feed water pumps 315 is: two small steam turbines and two 50% capacity feed water pumps 315 are arranged on the same floor with the large steam turbine (about at the power generation 12-14 meters away from the power plant room), but the two sets of front pump motors 317 and front pumps 316 respectively corresponding to these two sets of feed water pumps 315 are arranged on the zero-meter floor of the power plant ground, which are not on the same floor as the f...

Embodiment 2

[0147] In the second embodiment, a small steam turbine drives a 100% capacity feed water pump 315 to work. This structure is divided into Type A and Type B according to the different positions of the front pump 316 configured in the system.

[0148] Type A:

[0149] The structure of the original A-type steam-driven feedwater pump 315 made up of a 100% capacity feedwater pump 315 is: the small steam turbine and the feedwater pump 315 are arranged on the same floor with the large steam turbine (about 12-14 meters in the engine room of the power plant ), but the pre-pump motor 317 and the pre-pump 316 are arranged on the zero-meter floor of the power plant ground, and the layout of the feed water pump 315 is not on the same floor, that is, "a small steam turbine and a feed water pump 315" are in the machine room 12- The height of 14 meters, and the arrangement of "a front pump motor 317 and a front pump 316" at zero meters in the machine room.

[0150] like Figure 7 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com