Method for detecting industrial ammoximation reaction liquid of caprolactam

An ammoximation reaction and caprolactam technology, applied in the chemical industry, can solve the problems of interfering with the determination of impurities in the reaction solution, inability to accurately detect the composition of the reaction solution, and poor reproducibility of test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

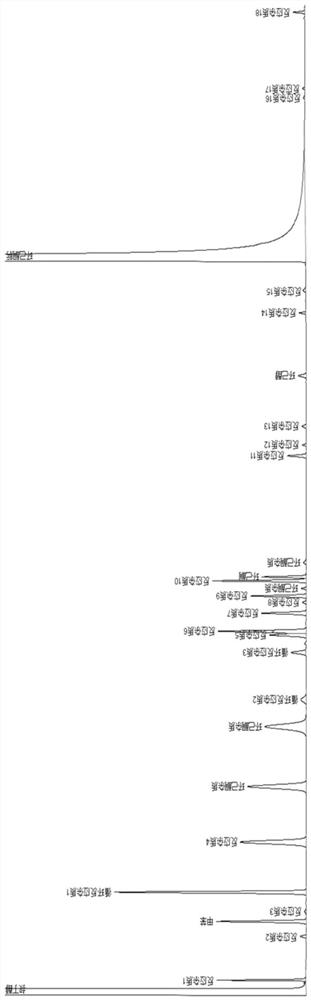

[0031] A chromatograph equipped with HP-INNOWAX 60m*0.32mm*0.25μm chromatographic column was used for detection and analysis. First use the pretreatment method to process the chromatographic empty run (no sample injection), and immediately use the gradient temperature rise scheme to detect the ammoximation reaction solution and circulating tert-butanol respectively. The chromatographic detection conditions are: inlet temperature 260°C, split ratio 30:1, sample volume 0.5μL; detector temperature 280°C, detector hydrogen flow rate 30ml / min, detector air flow rate 300ml / min; column carrier gas flow rate 1ml / min. In this example, the chromatographic conditions of the pretreatment method are adopted. The initial temperature is 40° C., kept for 1 min, and then raised to 200° C. at a rate of 20° C. / min, and kept for 1 min. This example adopts N=2 gradient heating scheme, the initial temperature is 40°C, keep for 15min, raise the temperature to 110°C at 10°C / min, keep for 10min, rais...

Embodiment 2

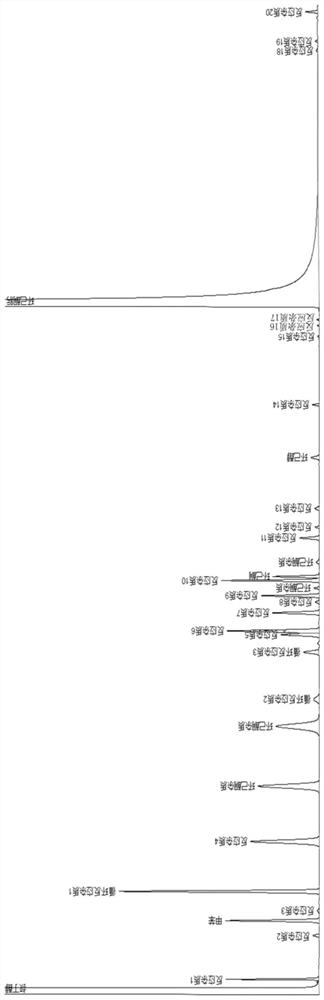

[0038] The chromatograph equipped with HP-INNOWAX 60m*0.32mm*0.5μm chromatographic column is used for detection and analysis. First use the pretreatment method to process the chromatographic empty run (no sample injection), and immediately use the gradient temperature rise scheme to detect the ammoximation reaction solution and circulating tert-butanol respectively. The chromatographic detection conditions are: inlet temperature 260°C, split ratio 30:1, sample volume 0.5μL; detector temperature 280°C, detector hydrogen flow rate 30ml / min, detector air flow rate 300ml / min; column carrier gas flow rate 1ml / min. In this embodiment, the chromatographic conditions of the pretreatment method are adopted. The initial temperature is 35° C., kept for 2 minutes, then raised to 200° C. at a rate of 15° C. / min, and kept for 2 minutes. This example adopts N=3 gradient heating scheme, the initial temperature is 35°C, keep for 10min, raise the temperature to 110°C at 10°C / min, keep for 10mi...

Embodiment 3

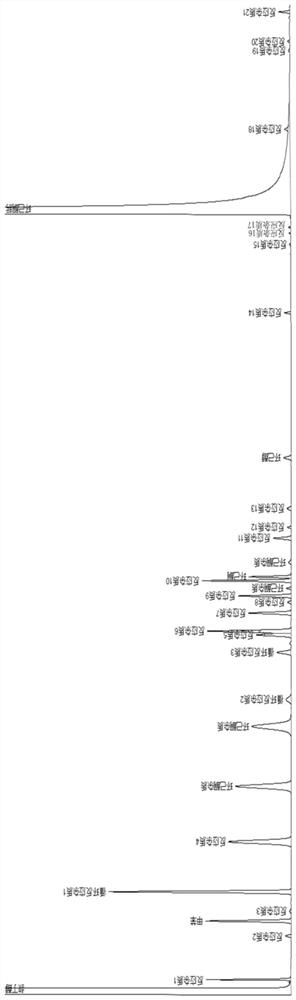

[0045]The chromatograph equipped with HP-INNOWAX 60m*0.25mm*0.5μm chromatographic column is used for detection and analysis. First use the pretreatment method to process the chromatographic empty run (no sample injection), and immediately use the gradient temperature rise scheme to detect the ammoximation reaction solution and circulating tert-butanol respectively. The chromatographic detection conditions are: inlet temperature 300°C, split ratio 50:1, sample volume 1μL; detector temperature 300°C, detector hydrogen flow rate 40ml / min, detector air flow rate 400ml / min; column carrier gas flow rate 2ml / min. In this example, the chromatographic conditions of the pretreatment method are adopted. The initial temperature is 30° C., kept for 1 min, and then raised to 220° C. at a rate of 20° C. / min, and kept for 1 min. This example adopts N=3 gradient heating scheme, the initial temperature is 30°C, keep it for 10min, raise the temperature to 90°C at 8°C / min, keep it for 12min, ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com