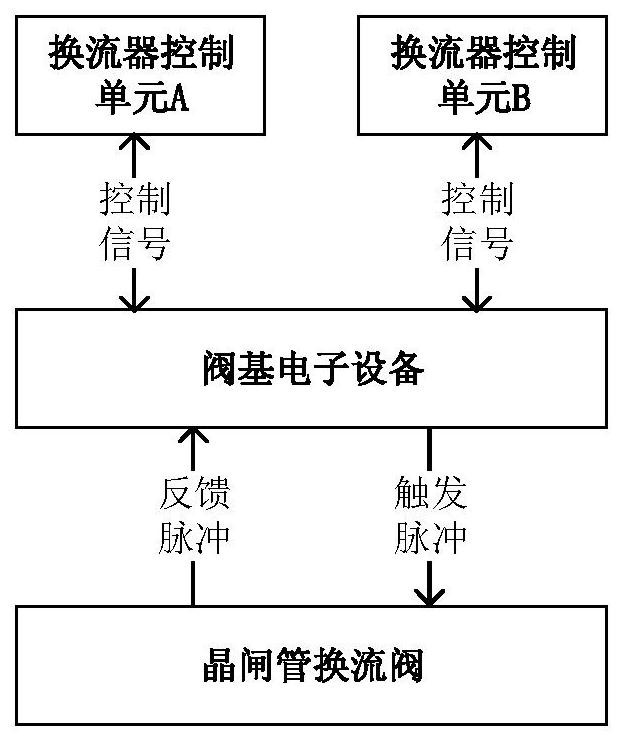

Thyristor converter valve base electronic equipment test system

A technology of valve-based electronic equipment and thyristor converter valves, which is applied in the field of thyristor converter valve-based electronic equipment testing systems, can solve problems such as project delays, difficulty, and inability to provide interface signal types and logical combinations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

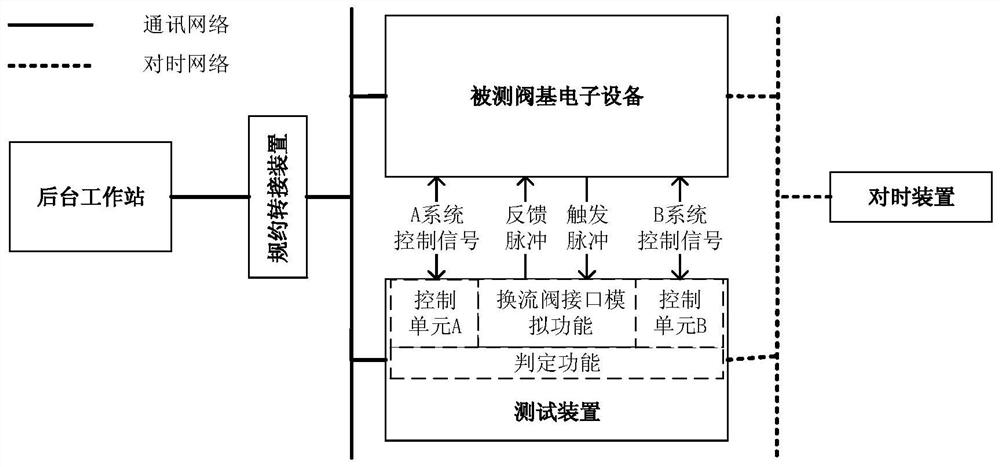

[0022] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 2 As shown, the present invention provides a thyristor converter valve valve base electronic equipment (referred to as VBE) testing system, including a background workstation, a network protocol conversion device, a timing device and a testing device, which are respectively introduced below:

[0024] The testing device provides a signal interface for the tested valve-based electronic equipment, and judges whether the function of the tested valve-based electronic equipment is normal according to the preset judgment logic. The testing device can complete the function simulation of the converter valve control unit in the redundant configuration mode, Implement active / standby mode switching.

[0025] The test device has the function of judging and outputting the operating state of the VBE device un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap