Three-dimensional simulation debugging and monitoring method for automatic production line

An automated production line and 3D simulation technology, applied in design optimization/simulation, general control system, control/regulation system, etc., can solve the problem of small capacity of state monitoring data, poor user experience, inability to design, implement, and verify mechanical and electrical parts issues of parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

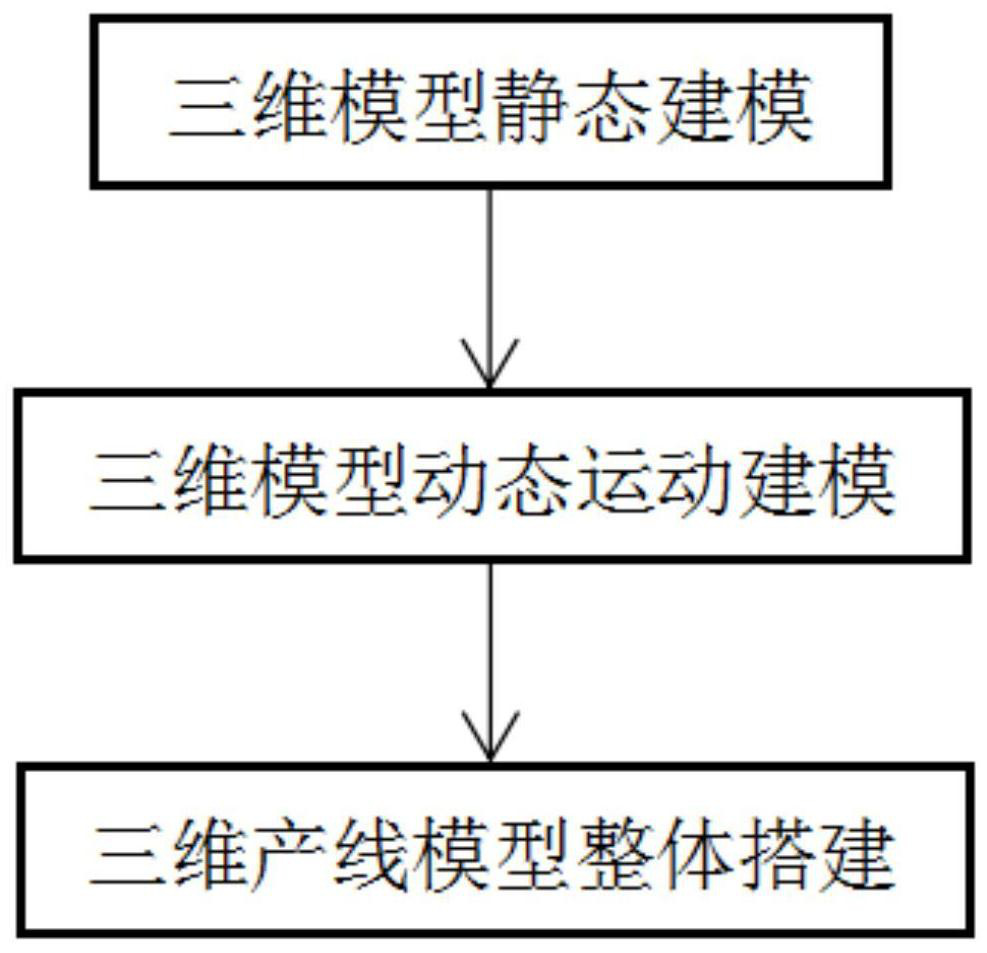

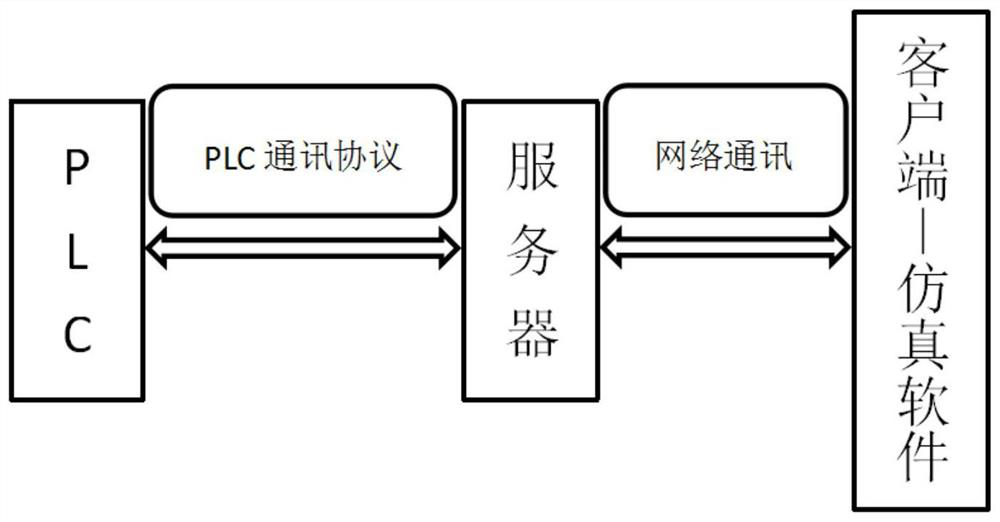

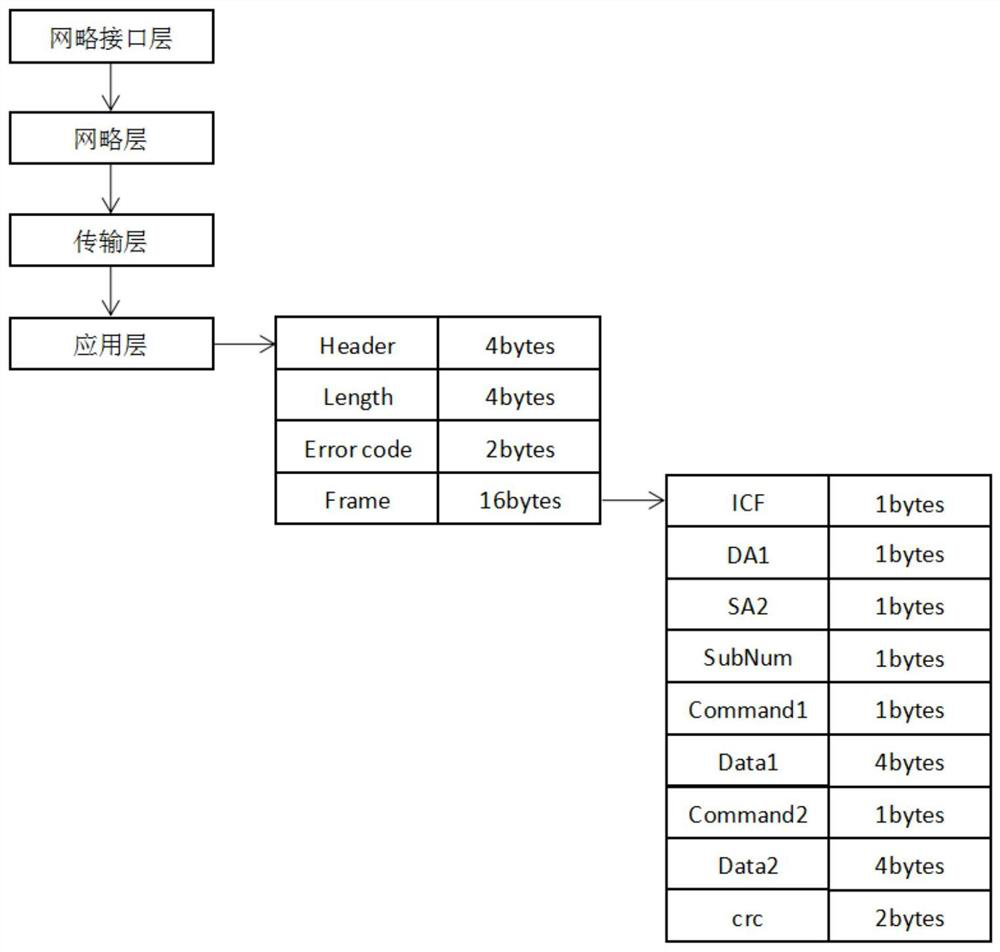

[0047] 1. A 3D simulation modeling method for an automated production line based on OpenGL simulation software.

[0048] OpenGL has advantages that other simulation software cannot match in the field of interactive 3D modeling and simulation. First of all, one of the biggest features of OpenGL is that it has nothing to do with hardware and can be implemented on different platforms; secondly, OpenGL has excellent functions on PCs and can provide a systematic solution for realizing realistic simulation effects and developing interactive 3D simulation applications. Finally, OpenGL has good openness, especially the seamless combination with Visual C++ object-oriented programming software, which can embed various simulation algorithms to realize real-time control of 3D models. The OpenGL drawing process follows a basic rendering sequence, that is, the rendering pipeline, which is also the basic method for OpenGL to process data. In this example, the simulation modeling of the 3D m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com