Electric push percussion device for percussing anastomat and electric anastomat

A stapler and electric technology, applied in anatomical instruments, medical science, surgery, etc., can solve the problems of anastomotic leakage, large differences in grip strength, and cumbersome manual operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

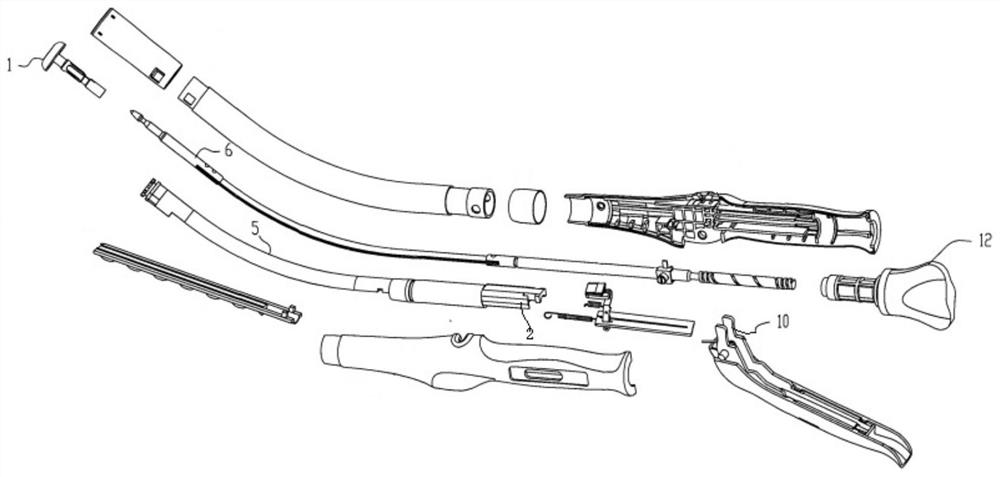

Embodiment 1

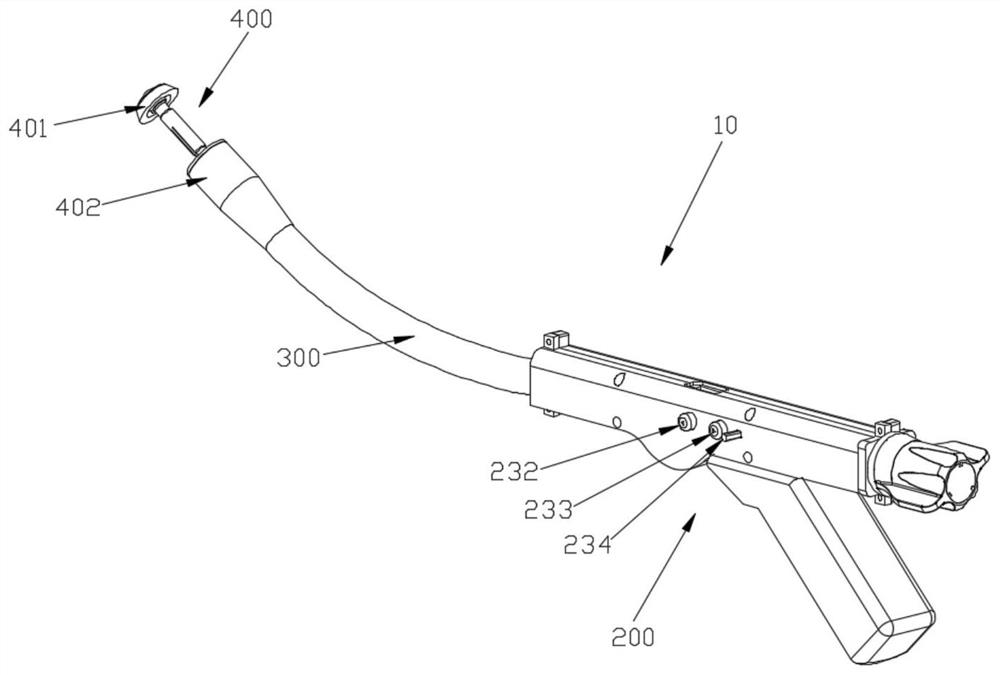

[0026] figure 2 An exemplary powered stapler 10 is shown for use in providing end-to-end stapling between two segments of an anatomical lumen, such as a portion of a patient's digestive tract. The surgical instrument 10 of this example includes a handle assembly 200 , a shaft tube 300 and an end effector 400 , wherein the end effector 400 includes a nail anvil 401 and a nail cartridge 402 . Shaft tube 300 extends distally from handle assembly 200 , and end effector 400 is coupled to the distal end of shaft tube 300 . Briefly, the handle assembly 200 is operable to actuate the end effector 400, selectively open and close the anvil 401 to clamp tissue between the anvil and the cartridge, and drive the staple cartridge 402. The cutting knife and staples in the knife cut through the tissue while the staples pass through the grooves of the tissue against the abutment to suture the tissue contained between the anvil and the staple cartridge.

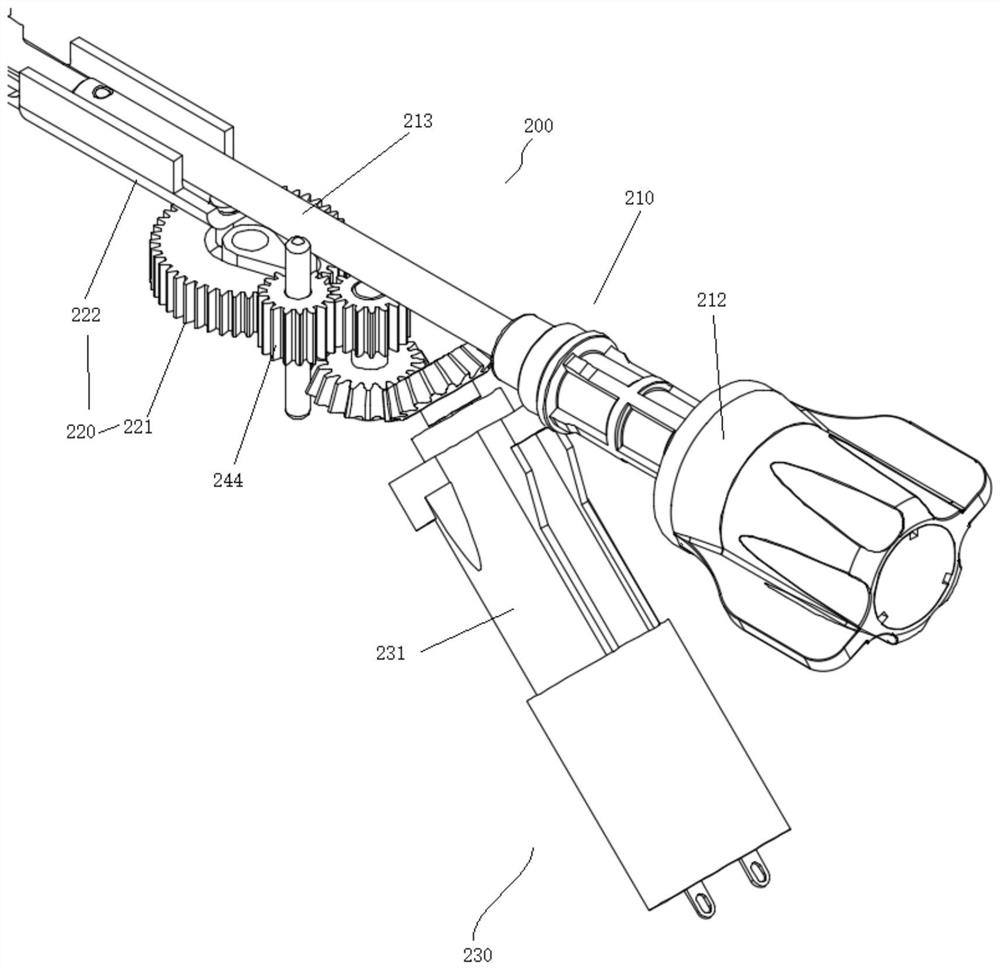

[0027] image 3 Handle assembly 200...

Embodiment 2

[0031] The electric stapler 10 includes a firing assembly 220 composed of a firing push rod 222 , a firing gear 221 , a pin 2214 , and a shaft 2212 in Embodiment 1, and a closing assembly 210 composed of a screw rod 213 and an adjusting nut 212 .

[0032] Such as Figure 7 The closure assembly 210 includes a threaded rod 213 , a rack 211 sleeved on a distal end of the threaded rod, and an adjusting nut 212 connected to a proximal end of the threaded rod 213 . The proximal end of the screw mandrel 213 is provided with a variable-pitch screw thread, and the adjusting nut 212 matches the thread of the screw mandrel 213. The rotation of the adjusting nut 212 will cause the screw mandrel 213 to move to the proximal end or the far end, and then control the screw mandrel 213 to be connected. The nail anvil 401 performs the clamping action of opening or closing. The variable pitch makes the anvil 401 move at different speeds in the longitudinal direction. When the adjusting nut 212 i...

Embodiment 3

[0040] Such as Figure 10 , the electric stapler 10 includes a firing assembly 220 composed of a firing push rod 222, a firing gear 221, a pin 2214, and a shaft 2212 in Embodiment 2, and a closing assembly 210 composed of a screw rod 213, and includes a plectrum 251, a positioning shaft 245, the driving assembly of transmission gear 244 and spring 252, the difference is that in this embodiment, the coupling part on the screw mandrel 213 that coincides with the transmission gear 244 is the basin gear 214, and the inner circumference of the basin gear 214 is threadedly matched with the outer circumference of the screw mandrel 213 The two sides of the basin gear 214 are abutted and limited by the stoppers 216 integrally connected with the shell of the stapler. The right end surface of the basin gear 214 is provided with a gear ring 2141. After the transmission gear 244 is pushed upward by the toggle assembly, the transmission gear 244 can mesh with the gear ring 2141, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com