Distributed closed dry dust removal system and dust removal method in return air lane

A technology for dry dust removal and return air lanes, applied in separation methods, chemical instruments and methods, dust prevention and other directions, can solve the problems of large resistance of dust collectors, large spray water consumption, increase roadway resistance, etc., and reduce the resistance of dust collectors. , Increase the filtration efficiency and reduce the effect of filtering airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

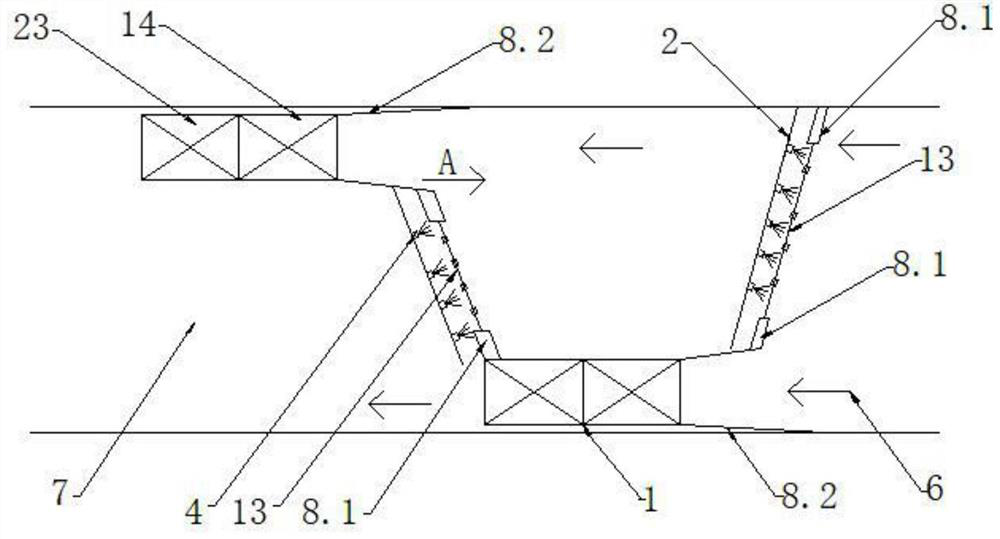

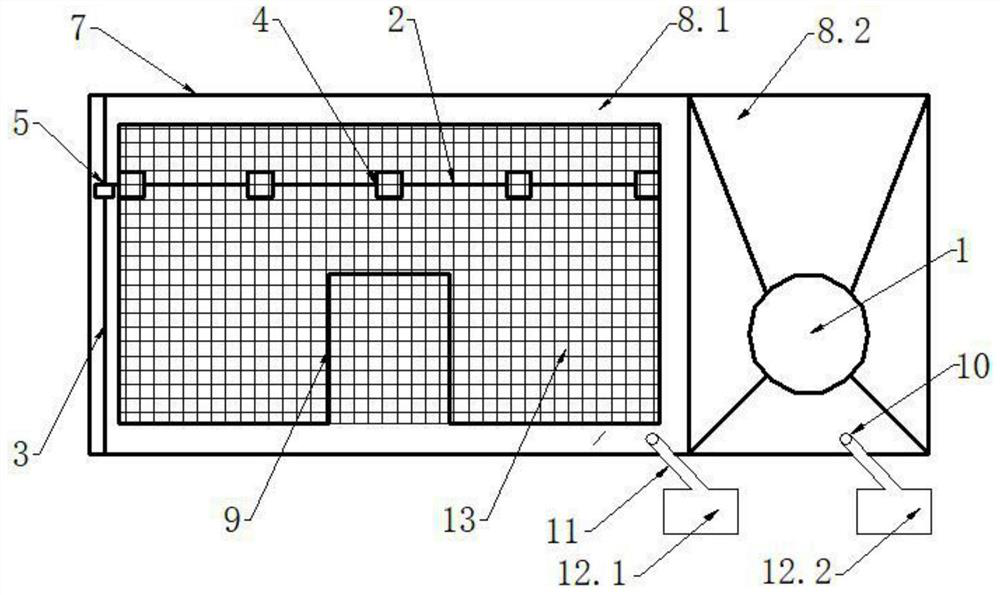

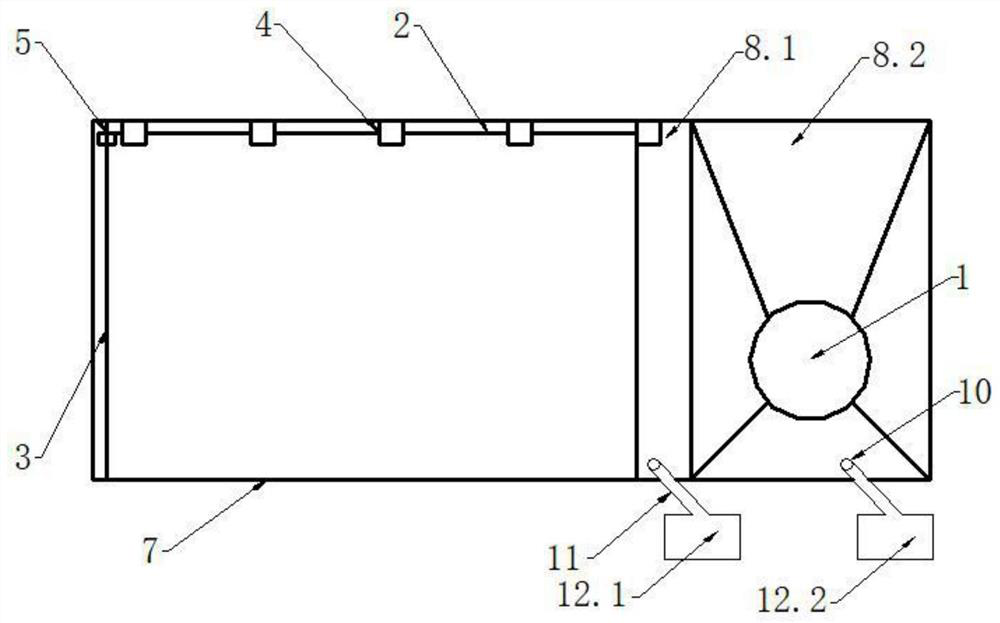

[0090] A distributed airtight dry dust removal system and a dust removal method for a return airway, the specific examples of which are as follows:

[0091] The total air volume Q of the return airway that needs to be treated 总 1500m 3 / min, front side dust collector processing air volume Q 1 Choose 600m 3 / min, the air volume Q of the rear side dust collector 3 Choose 500m 3 / min, you can obtain:

[0092] Front side filter handles air volume Q 2 =Q 总 -Q 1 =1500-600=900m 3 / min

[0093] Rear filter handles air volume Q 4 =Q 总 -Q 1 -Q 3 =1500-600-500=400m 3 / min

[0094] Resistance coefficient k of the selected front filter 2 is 1Pa·s / m, the drag coefficient k of the selected rear filter 4 2Pa·s / m, the filter area of the front filter is s 2 20m 2 , the filter area s of the rear filter 4 19m 2 ,but

[0095] The initial resistances of the front and rear filters are:

[0096] P 02 =k 2 Q 2 / s 2 =1×900 / 20=45Pa

[0097] P 04 =k 4 Q 4 / s 4 =2×400 / 19=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com