Material cooling conveyor with steel belt surface cleaning and protection functions

A technology for cooling conveyors and surface cleaning, which is applied to conveyors, conveyor objects, and devices for coating liquid on the surface, etc., and can solve problems such as poor reliability, slipping of supporting wheels, and affecting the heat transfer and cooling effect of the steel belt surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

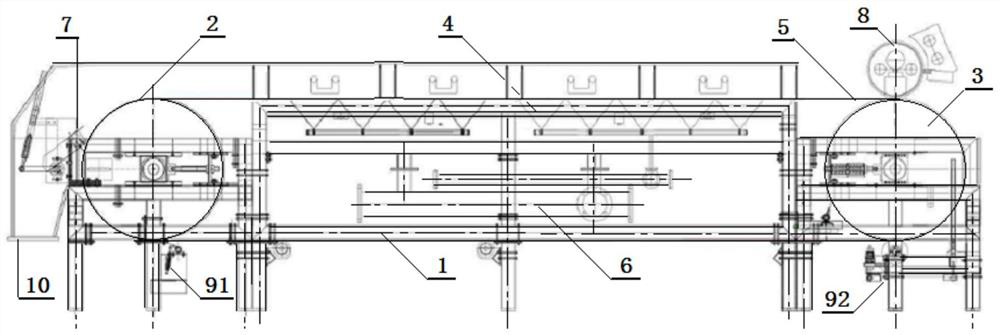

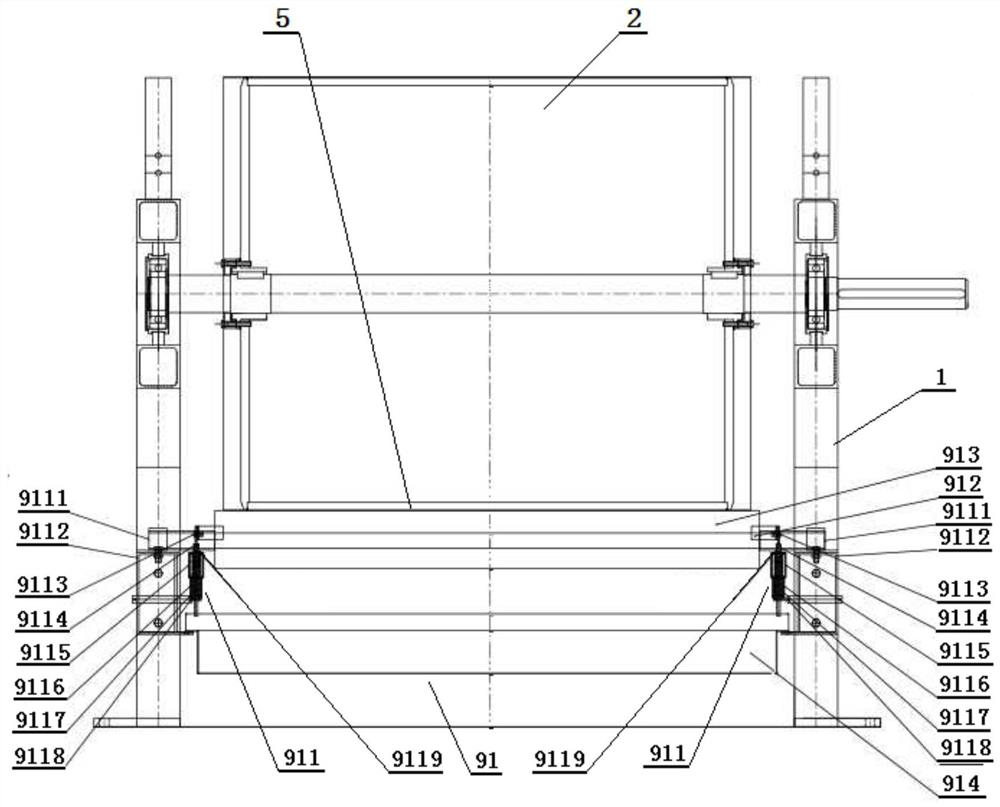

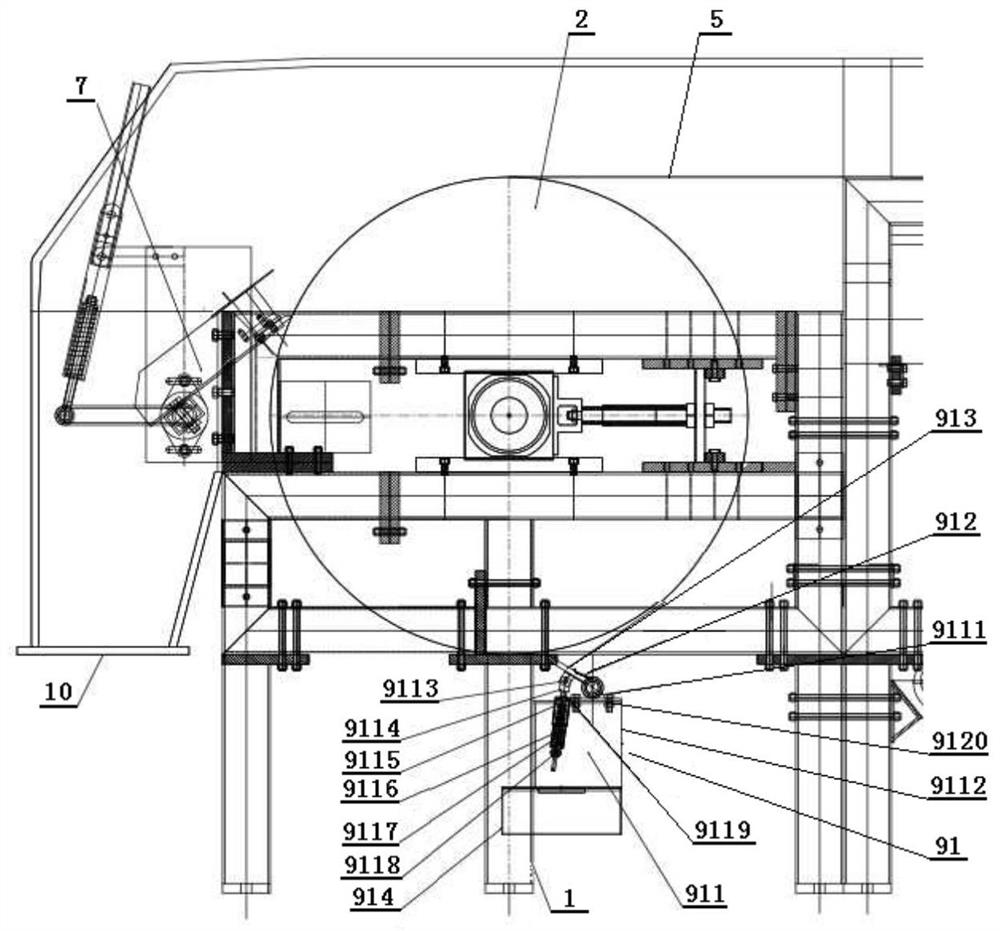

[0048] exist figure 1 Among them, a material cooling conveyor with the functions of cleaning and protecting the steel belt surface of the present invention mainly includes a frame 1, a main driving drum 2 and a driven tensioning drum 3 respectively arranged at the front and rear ends of the frame, and the The steel belt carrying platform 4 between the left and right side frames of the frame, the closed loop steel belt 5 arranged between the main driving drum 2 and the driven tensioning drum 3, and the water cooling cooling mechanism 6 arranged under the steel belt carrying platform 4, The molten material distributor 8 arranged above the driven tension drum 3, and the unloading scraper 7 and the unloading hopper 10 arranged on the side of the main driving drum 2 are characterized in that: it also includes a The steel belt surface cleaning mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com