High-temperature stabilizer for high-density cement paste, and preparation method thereof

A technology of high temperature stabilizer and cement slurry, which is applied in the field of downhole operations in oil and gas fields, and can solve problems such as unfavorable industrial production and complex preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

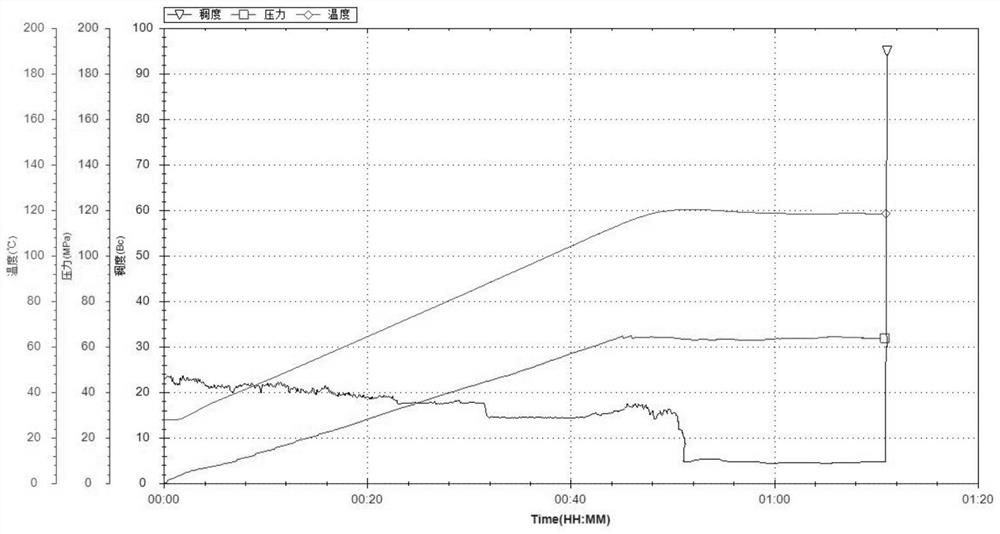

Embodiment 1

[0036] A high-temperature stabilizer for high-density cement slurry, the preparation method of which is as follows:

[0037] 1) Slowly add 15g of Diyou gum to 80g of water, stir the solution continuously during the adding process, and control the stirring rate between 300-500r / min; NaOH and 5g of 2-acrylamide-2-methylpropanesulfonic acid, continue to stir until they are completely dissolved, and dropwise add NaOH solution until the pH of the solution is 5; heat the reaction solution to 60°C, add 0.2g of ammonium persulfate to carry out Free radical polymerization reaction, and continue to react for 4h, spray drying to make a uniform powdery solid, which is modified diyou gum;

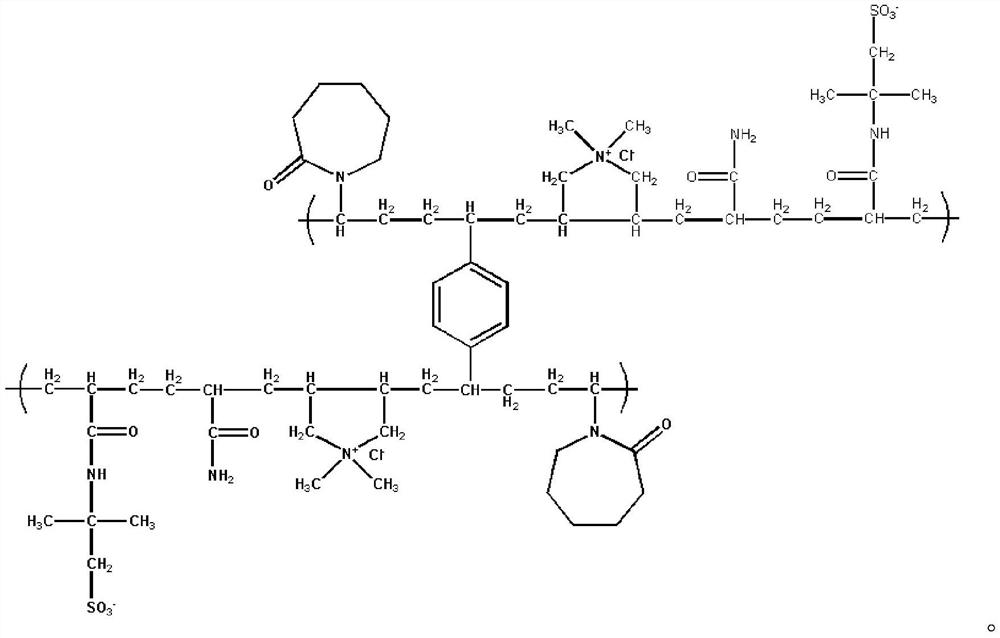

[0038]2) Weigh 40g 2-acrylamido-2-methylpropanesulfonic acid, 15g acrylamide, 16.7g dimethyl diallyl ammonium chloride (60% solution), 35g N-vinyl caprolactam, 2g Dissolve divinylbenzene in 400g of water so that the monomer mass fraction in the resulting solution is 20%; add sodium hydroxide to adjust ...

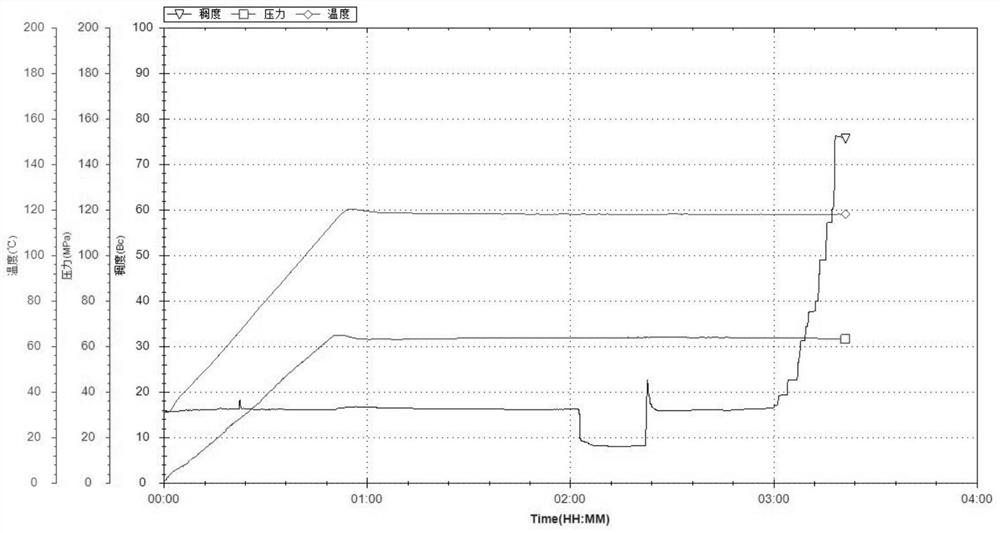

Embodiment 2

[0041] A high-temperature stabilizer for high-density cement slurry, the preparation method of which is as follows:

[0042] 1) Slowly add 12g of Diyoujiao to 70g of water, stir the solution continuously during the adding process, the stirring rate is controlled between 300-500r / min; NaOH and 10g of 2-acrylamide-2-methylpropanesulfonic acid, continue to stir until they are completely dissolved, add NaOH solution dropwise until the pH of the solution is 5, heat the reaction solution to 60°C, add 0.3g of ammonium persulfate to initiate the reaction , after reacting for 4 hours, spray-dry to make a uniform powdery solid for subsequent use;

[0043] 2) Weigh 41.5g of 2-acrylamido-2-methylpropanesulfonic acid, 17.8g of acrylamide, 10.8g of dimethyl diallyl ammonium chloride (60% solution), 27.8g of N -Vinylcaprolactam, 1.30g of divinylbenzene was added in 533g of water, so that the monomer mass fraction in the resulting solution was 15%; sodium hydroxide was added to adjust the pH...

Embodiment 3

[0046] A high-temperature stabilizer for high-density cement slurry, the preparation method of which is as follows:

[0047] 1) Slowly add 10g of Diyou gum to 60g of water, stir the solution continuously during the addition process, and control the stirring rate between 300-500r / min; when the undetermined gum is fully hydrated and appears colloidal, add 5g of p-styrene Sodium sulfonate and 10g 2-acrylamide-2-methylpropanesulfonic acid, continue to stir until they are all dissolved, and add NaOH solution dropwise until the pH of the solution is 5.5 to obtain a reaction mixture; add 0.5g initiator I to the reaction mixture Carry out free radical polymerization, and continue to react for 4 hours, spray dry to make uniform powdery solid, which is modified diyou gum;

[0048] 2) Weigh 50g of 2-acrylamido-2-methylpropanesulfonic acid, 20g of acrylamide, 8.34g of dimethyl diallyl ammonium chloride (60% solution), 25g of N-vinylcaprolactam, 1g Divinylbenzene is dissolved in 476g wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com